For Immediate Release.

IDTechEx Asks if Tesla’s Humanoid Robot “Optimus” Will Really Be Able to Serve People

IDTechEx.

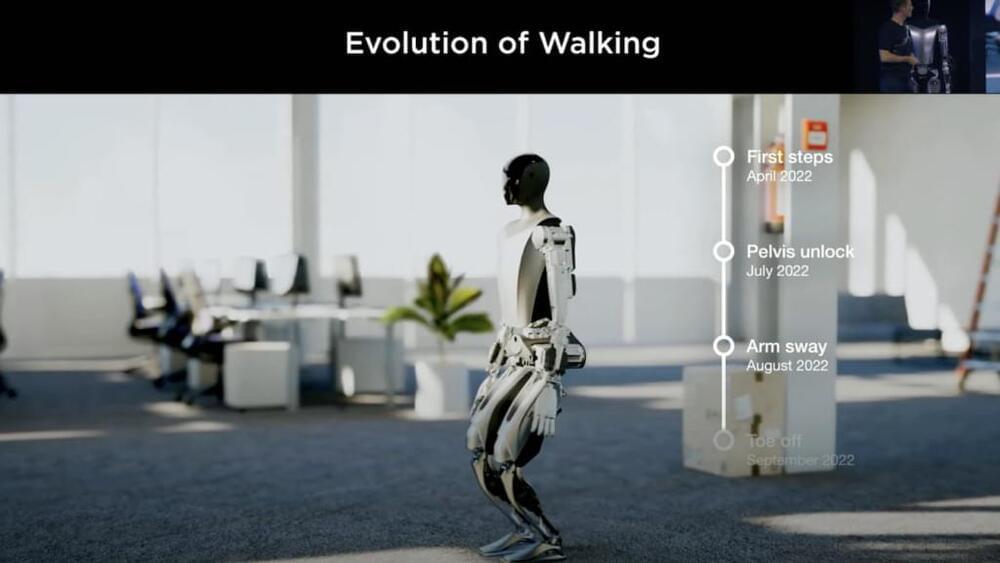

I’m not a robotics expert, so I’ve been particularly keen to hear what robotics experts think of Tesla’s Optimus presentation the other day. The core arguments from Elon Musk and many Tesla fans regarding why Optimus is such a big deal are: Tesla will find a way to mass produce it at relatively low cost, Tesla is adding a brain to the robot, and it needs to be in the form of a human so that it can perform tasks designed to be done by humans. I don’t see any strong arguments against those things, but I know they are broad-brushed claims and quite vague. What about the details that I can’t see, that a common Tesla fan can’t see, and that perhaps even an engineer working on Optimus can’t see?

Let’s start with Dennis Hong. Dennis is a professor of mechanical & aerospace engineering at UCLA. He’s Director of RoMeLa: Robotics & Mechanisms Laboratory. With this title and being an independent expert in the separate world of academia, I was particularly interested to see his opinion. He was clearly excited as AI Day 2 arrived, but not in a sycophantic way. Luckily, he put his thoughts in a good little 13-post Twitter thread.

Scientists trained a machine learning tool to capture the physics of electrons moving on a lattice using far fewer equations than would typically be required, all without sacrificing accuracy. A daunting quantum problem that until now required 100,000 equations has been compressed into a bite-size task of as few as four equations by physicists using artificial intelligence. All of this was accomplished without sacrificing accuracy. The work could revolutionize how scientists investigate systems containing many interacting electrons. Furthermore, if scalable to other problems, the approach could potentially aid in the design of materials with extremely valuable properties such as superconductivity or utility for clean energy generation.

From an AI that makes videos from text prompts to a robot running track, check out this week’s awesome tech stories from around the web.

Researchers at Google Deepmind and the University of Oxford have concluded that it’s now “likely” that superintelligent AI will spell the end of humanity — a grim scenario that more and more researchers are starting to predict.

In a recent paper published in the journal AI Magazine, the team — comprised of DeepMind senior scientist Marcus Hutter and Oxford researchers Michael Cohen and Michael Osborne — argues that machines will eventually become incentivized to break the rules their creators set to compete for limited resources or energy.

“Under the conditions we have identified, our conclusion is much stronger than that of any previous publication — an existential catastrophe is not just possible, but likely,” Cohen, Oxford University engineering student and co-author of the paper, tweeted earlier this month.

What about the Chinese Room thought experiment by Searle, doesn’t that disprove true AI and mind uploading?

The Chinese Room Argument is a thought experiment designed by philosopher John Searle and published in his article, Can Computers Think? This experiment is in opposition to strong-artificial intelligence (AI), specifically to claims that computers may someday be able to have cognitive states. Searle argues that cognitive states must have semantic content, yet programs are purely syntactic, and that computers are constrained by structures that disallow them from creating their own meaning.

To make this argument, Searle imagines a “Chinese Room” in which a person receives a string of Chinese characters, and using a computer, returns the appropriate response in Chinese. The person has no understanding of the Chinese language yet using syntactic and instructions, the person is able to mimic an understanding of Chinese. Searle demonstrates that an ability to follow formal instructions and produce appropriate responses does not equate to an understanding, due to the lack of semantic content. Similarly, a computer that substitutes for said person, would not understand Chinese.

Microgrids are the right solution for rural and remote energy production and distribution because they are grids designed for smaller populations.

In the United States, there are at least 60,000 people who have no access to electricity. It is not a large number but poses for this population a barrier to participating in the modern world. You cannot find a job working from home without electricity and Internet access. You cannot visit your doctor virtually. You cannot use electricity to light and heat your home.

But with microgrids that can operate autonomously from the main power grid, rural and remote communities can do everything that people living in big cities can do leading to a better quality of life for those living there.

A Toronto, Canada, based company is a microgrid solutions provider. Called Clear Blue Technologies, it offers energy-as-a-service to rural and remote communities. In Nigeria, it is installing microgrids and distributed energy solutions to help rural communities to access energy and telecommunications services. Its service model manages these installations remotely at a low cost delivering clean renewable electricity while giving rural users access to the Internet. For Nigerian remote communities, it brings them into the 21st century. That’s why in March of this year, Clear Blue was awarded a contract covering 120 telecommunications sites across the country with plans in the next five years to grow that number to 1,060. Talk about levelling the playing field for these communities to give them access to clean energy and cellular phone services.

An electrolyte moves ions – atoms that have been charged by either gaining or losing an electron – between the two electrodes in a battery. Lithium ions are created at the negative electrode, the anode, and flow to the cathode where they gain electrons. When a battery charges, the ions move back to the anode.

Battery innovations can take years to come to fruition because there are so many different chemicals involved in their production. Working out the ratio of chemicals and optimising them for peak use can be an arduous task.

However, when the research team used an automated arrangement of pumps, valves, vessels, and other lab equipment to mix together three potential solvents and one salt, and then fed those results through ‘Dragonfly’, they found that the AI delivered six solutions that out-performed an existing electrolyte solution.

Artificial intelligence researchers are doubling down on the concept that we will see artificial general intelligence (AGI) — that’s AI that can accomplish anything humans can, and probably many we can’t — within our lifetimes.

Responding to a pessimistic op-ed published by TheNextWeb columnist Tristan Greene, Google DeepMind lead researcher Dr. Nando de Freitas boldly declared that “the game is over” and that as we scale AI, so too will we approach AGI.

Greene’s original column made the relatively mainstream case that, in spite of impressive advances in machine learning over the past few decades, there’s no way we’re gonna see human-level artificial intelligence within our lifetimes.