Neuromorphic chips mimic the brain to deliver faster, lower-power AI. Explore where this next-gen tech could make the biggest impact.

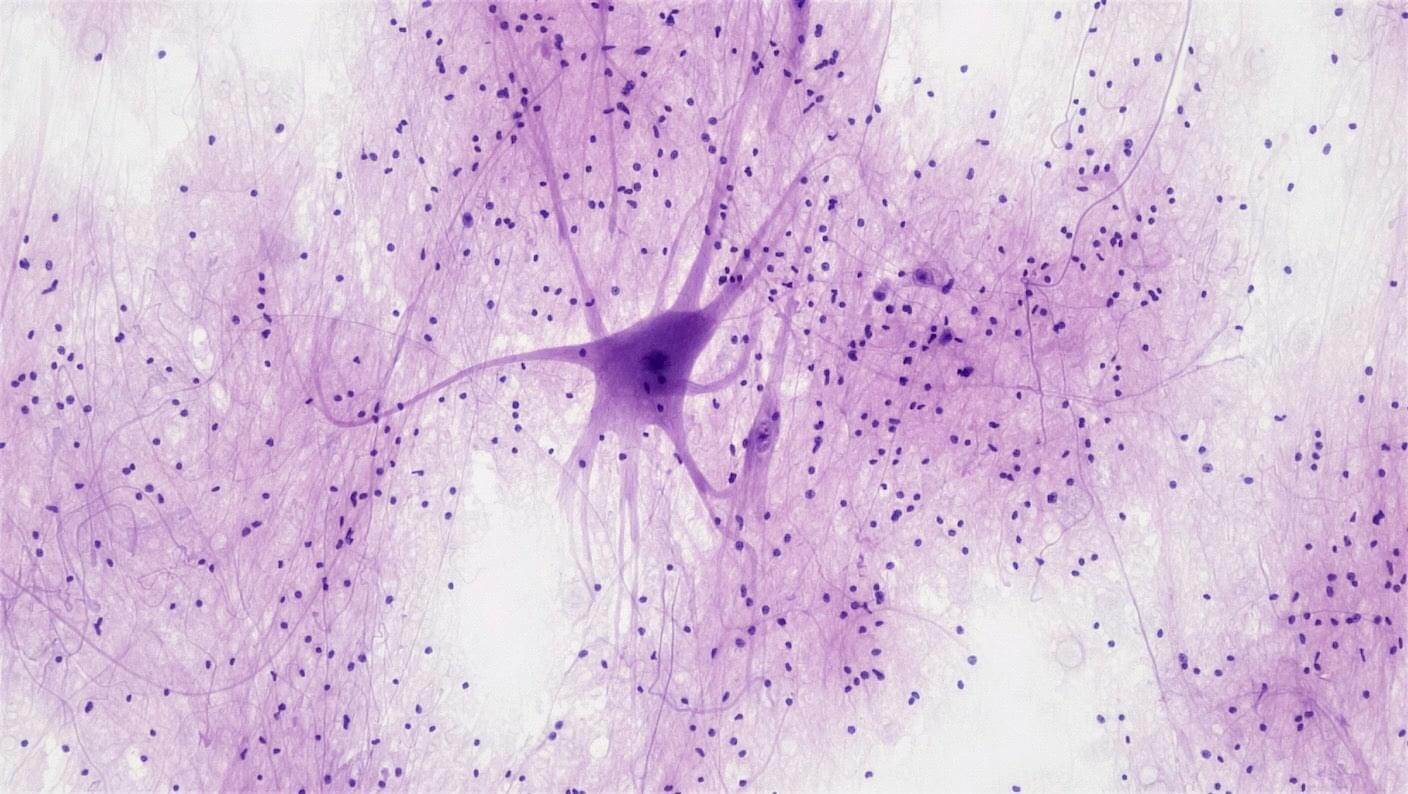

For every motor skill you’ve ever learned, whether it’s walking or watchmaking, there is a small ensemble of neurons in your brain that makes that movement happen. Our brains trigger these ensembles—what we sometimes call “muscle memories”—to get our bodies cooking, showering, typing, and every other voluntary thing we do.

Watching the robot crawl around is amusing, but the study’s main goal is to see if a biohybrid robot can form a sort of long-lasting biological “mind” that directs movement. Neurons are especially sensitive cells that rapidly stop working or even die outside of a carefully controlled environment. Using blob-like amalgamations of different types of neurons to direct muscles, the sponge-bots retained their crawling ability for over two weeks.

Scientists have built biohybrid bots that use electricity or light to control muscle cells. Some mimic swimming, walking, and grabbing motions. Adding neurons could further fine-tune their activity and flexibility and even bestow a sort of memory for repeated tasks.

These biohybrid bots offer a unique way to study motion, movement disorders, and drug development without lab animals. Because their components are often compatible with living bodies, they could be used for diagnostics, drug delivery, and other medical scenarios.

Artificial intelligence is now part of our daily lives, with the subsequent pressing need for larger, more complex models. However, the demand for ever-increasing power and computing capacity is rising faster than the performance traditional computers can provide.

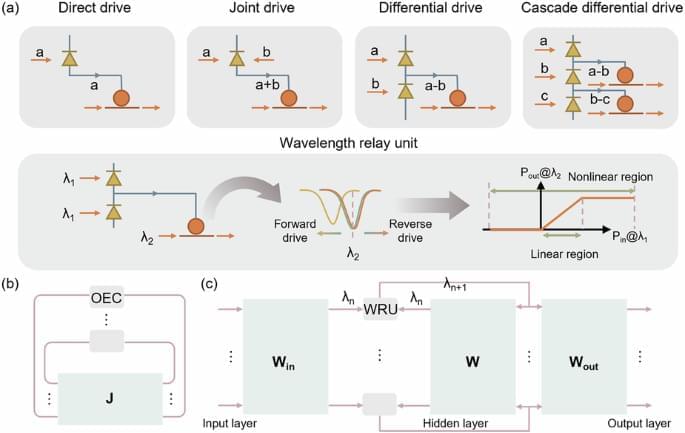

To overcome these limitations, research is moving towards innovative technologies such as physical neural networks, analog circuits that directly exploit the laws of physics (properties of light beams, quantum phenomena) to process information. Their potential is at the heart of the study published in the journal Nature. It is the outcome of collaboration between several international institutes, including the Politecnico di Milano, the École Polytechnique Fédérale in Lausanne, Stanford University, the University of Cambridge, and the Max Planck Institute.

The article entitled “Training of Physical Neural Networks” discusses the steps of research on training physical neural networks, carried out with the collaboration of Francesco Morichetti, professor at DEIB—Department of Electronics, Information and Bioengineering, and head of the university’s Photonic Devices Lab.

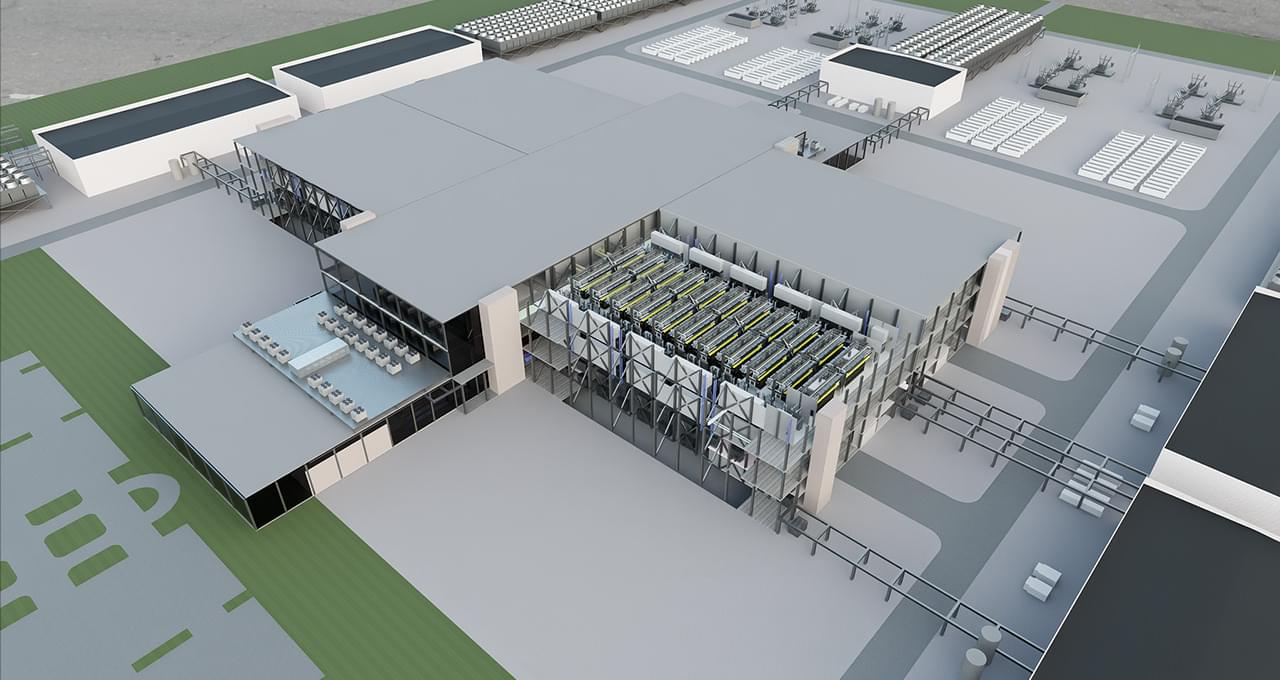

At this week’s AI Infrastructure Summit in Silicon Valley, NVIDIA’s VP of Accelerated Computing Ian Buck unveiled a bold new vision: the transformation of traditional data centers into fully integrated AI factories.

As part of this initiative, NVIDIA is developing reference designs to be shared with partners and enterprises worldwide — offering an NVIDIA Omniverse Blueprint for building high-performance, energy-efficient infrastructure optimized for the age of AI reasoning.

Already, NVIDIA is collaborating with scores of companies across every layer of the stack, from building design and grid integration to power, cooling and orchestration.

Motor brain–computer interfaces (BCIs) decode neural signals to help people with paralysis move and communicate. Even with important advances in the past two decades, BCIs face a key obstacle to clinical viability: BCI performance should strongly outweigh costs and risks. To significantly increase the BCI performance, we use shared autonomy, where artificial intelligence (AI) copilots collaborate with BCI users to achieve task goals. We demonstrate this AI-BCI in a non-invasive BCI system decoding electroencephalography signals. We first contribute a hybrid adaptive decoding approach using a convolutional neural network and ReFIT-like Kalman filter, enabling healthy users and a participant with paralysis to control computer cursors and robotic arms via decoded electroencephalography signals. We then design two AI copilots to aid BCI users in a cursor control task and a robotic arm pick-and-place task. We demonstrate AI-BCIs that enable a participant with paralysis to achieve 3.9-times-higher performance in target hit rate during cursor control and control a robotic arm to sequentially move random blocks to random locations, a task they could not do without an AI copilot. As AI copilots improve, BCIs designed with shared autonomy may achieve higher performance.

Published September 2025 Nature Machine Intelligence:

Preprint: 2024 Oct 12:2024.10.09. https://pmc.ncbi.nlm.nih.gov/articles/PMC11482823/