If you’re a programmer seeking to develop cost-free code for your projects while saving time and effort, explore these AI tools that help you generate free code.

Researchers who created a soft robot that could navigate simple mazes without human or computer direction have now built on that work, creating a “brainless” soft robot that can navigate more complex and dynamic environments. The paper, “Physically Intelligent Autonomous Soft Robotic Maze Escaper,” was published Sept. 8 in the journal Science Advances.

“In our earlier work, we demonstrated that our soft robot was able to twist and turn its way through a very simple obstacle course,” says Jie Yin, co-corresponding author of a paper on the work and an associate professor of mechanical and aerospace engineering at North Carolina State University. “However, it was unable to turn unless it encountered an obstacle. In practical terms this meant that the robot could sometimes get stuck, bouncing back and forth between parallel obstacles.

We’ve developed a new soft robot that is capable of turning on its own, allowing it to make its way through twisty mazes, even negotiating its way around moving obstacles. And it’s all done using physical intelligence, rather than being guided by a computer.

In an effort to create robots capable of controlling their own life-cycles, researchers have developed squishy little devices that can melt themselves into a puddle of goo.

“We have mimicked death in a life cycle where the robot could end itself,” Seoul National University engineer Min-Ha Oh told Peter Grad at Tech Xplore.

This ‘death’ is triggered by internal ultraviolet LEDs that destabilize the chemical composition of the robot. This process takes about an hour though, so it’s likely we have a few decades before we’ll see robots being employed as the kinds of vanishing spies proposed by the researchers.

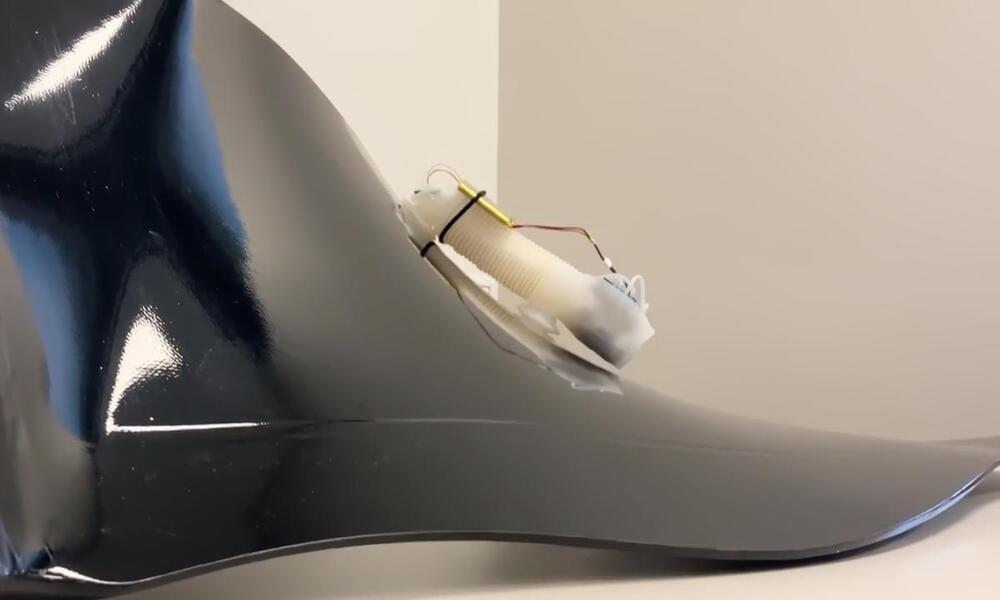

GE Aerospace has demonstrated a worm-like robot that could one day inspect and repair jet engines. The Sensiworm (Soft ElectroNics Skin-Innervated Robotic Worm) is designed to serve as “extra sets of eyes and ears” for service operators as they examine the insides of aircraft. GE says the soft robot can minimize downtime and perform less invasive inspections and, in the future, make repairs itself.

The company compares the Sensiworm’s role in aerospace engineering and repairs to how soft robotics have allowed for minimally intrusive patient surgeries. “These technologies are enabling less invasive inspection and repair of jet engines on the wing to reduce downtime,” the company wrote. GE says the worm-like machine could give operators “virtually unfettered access” to inspect engines without disassembling them.

Resembling an inchworm, the Sensiworm (remote-controlled by operators) can crawl across various engine parts, including rotating wind turbine blades. It can sense and avoid obstacles automatically, reach places where gravity may stop other tools (thanks to its suction-cup feet) and measure the thickness of thermal barrier coatings. GE says it can even sniff out gas leaks. “With their soft, compliant design, they could inspect every inch of a jet engine, transmitting live video and real-time data about the condition of parts that operators typically check,” the company wrote.

Yet the automation of such tasks also means the chance to eliminate or reduce certain roles, not just in administration, but across many fields as the technology becomes more sophisticated. According to a survey of professionals by Thomson Reuters published last week, 67% of respondents believe AI will have a great impact on their profession in the next five years, while more than half predict the technology will create new career paths.

So exactly what are those new professional opportunities that the next generation of workers should be trying to pursue?

“There is no such thing as a future-proof career anymore,” says Dr Andrew Rogoyski, the director of innovation and partnerships at the Surrey Institute for People-Centred Artificial Intelligence at the University of Surrey.

Concrete is responsible for 8 percent of the world’s carbon emissions.

In construction, concrete emissions refer to the greenhouse gas emissions associated with the production and use of concrete, one of the most widely used construction materials globally. Due to energy-intensive cement production processes and chemical reactions that take place during concrete curing, the concrete industry is a substantial source of carbon dioxide (CO2) emissions, responsible for an estimated 8 percent of the world’s emissions.

Cement, which is a byproduct of heating limestone (calcium carbonate) and other minerals to high temperatures in a kiln, is the main component of concrete. In order to produce the… More.

Jewett is on the hunt for materially efficient components that can be utilized to construct structures such as bridges and buildings. He does this through the use of computational power. During his work, he also takes into account additional restrictions, particularly making sure the manufacturing cost isn’t too expensive.

Before beginning his PhD studies, Jewett worked in the construction industry, he spent a year and a half as a structural engineer in New York City, which gave him a knack for producing work that can actually be put into practice. Jewett adds that the sooner he can complete his work, the better.

“The time horizon of when these things need to be implemented is relatively short if we want to make an impact before global temperatures have already risen too high. My PhD research will be developing a framework for how that could be done with concrete construction, but I’d like to keep thinking about other materials and construction methods even after this project is finished,” explained the student.