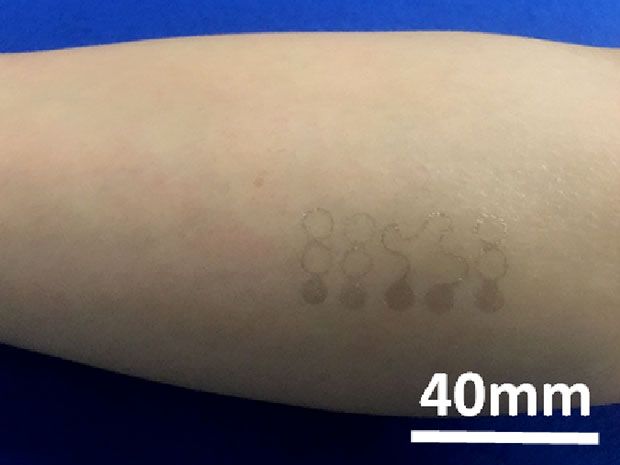

The graphene temporary tattoo seen here is the thinnest epidermal electronic device ever and according to the University of Texas at Austin researchers who developed it, the device can take some medical measurements as accurately as bulky wearable sensors like EKG monitors. From IEEE Spectrum:

Graphene’s conformity to the skin might be what enables the high-quality measurements. Air gaps between the skin and the relatively large, rigid electrodes used in conventional medical devices degrade these instruments’ signal quality. Newer sensors that stick to the skin and stretch and wrinkle with it have fewer airgaps, but because they’re still a few micrometers thick, and use gold electrodes hundreds of nanometers thick, they can lose contact with the skin when it wrinkles. The graphene in the Texas researchers’ device is 0.3-nm thick. Most of the tattoo’s bulk comes from the 463-nm-thick polymer support.

The next step is to add an antenna to the design so that signals can be beamed off the device to a phone or computer, says (electrical engineer Deji) Akinwande.