Circa 2015

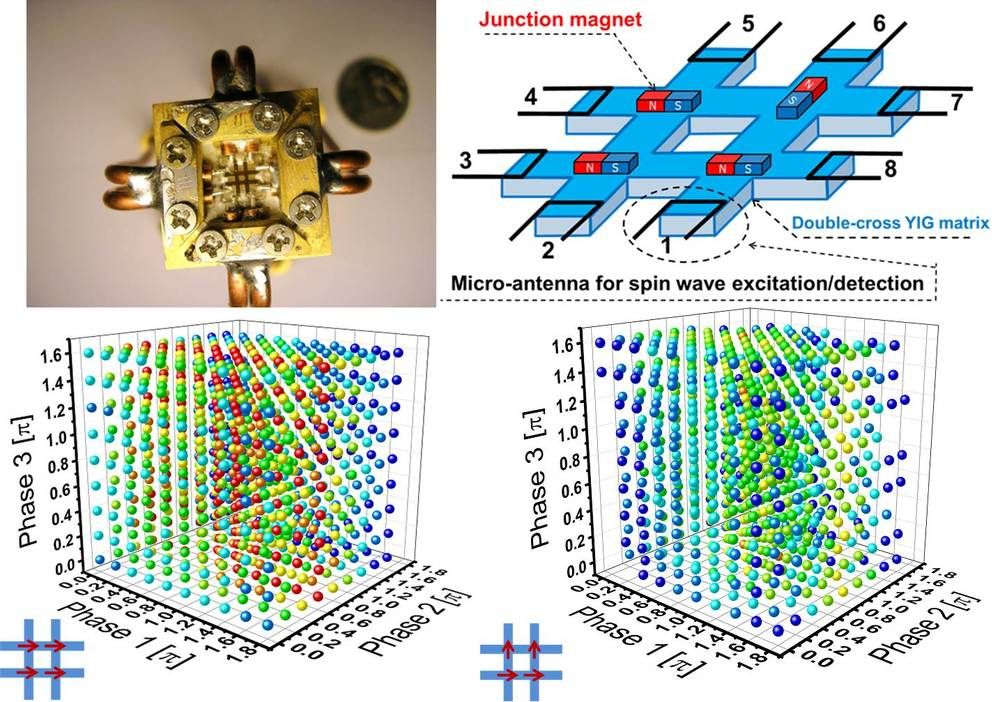

Researchers at the University of California, Riverside Bourns College of Engineering and the Russian Academy of Sciences have successfully demonstrated pattern recognition using a magnonic holographic memory device, a development that could greatly improve speech and image recognition hardware.

Pattern recognition focuses on finding patterns and regularities in data. The uniqueness of the demonstrated work is that the input patterns are encoded into the phases of the input spin waves.

Spin waves are collective oscillations of spins in magnetic materials. Spin wave devices are advantageous over their optical counterparts because they are more scalable due to a shorter wavelength. Also, spin wave devices are compatible with conventional electronic devices and can be integrated within a chip.