“The partners are working together to develop the world’s first laboratory-produced chicken nuggets. The 3D printed nuggets are expected to be similar in taste and appearance to KFC’s original product, but will have the benefit of being more environmentally friendly to produce.”

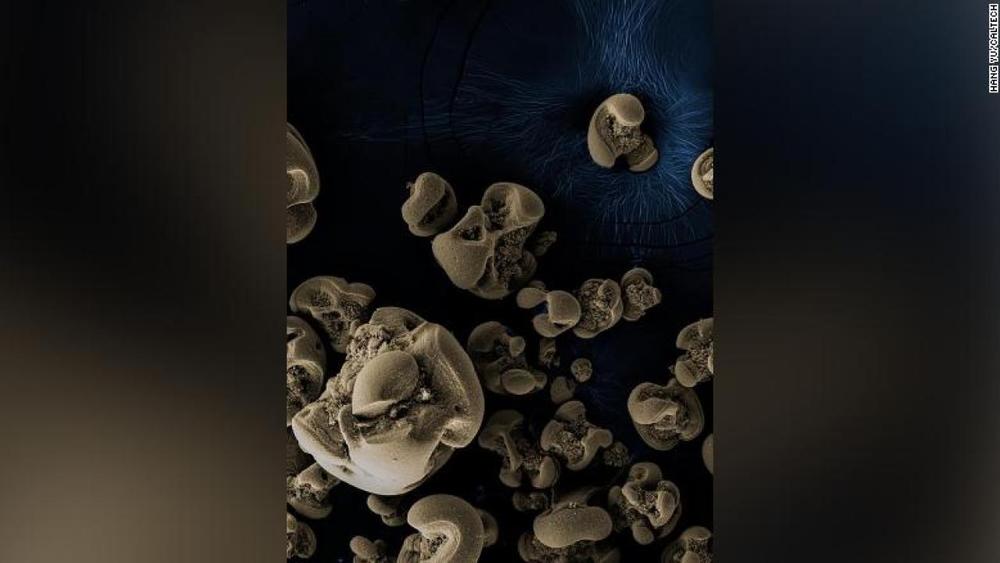

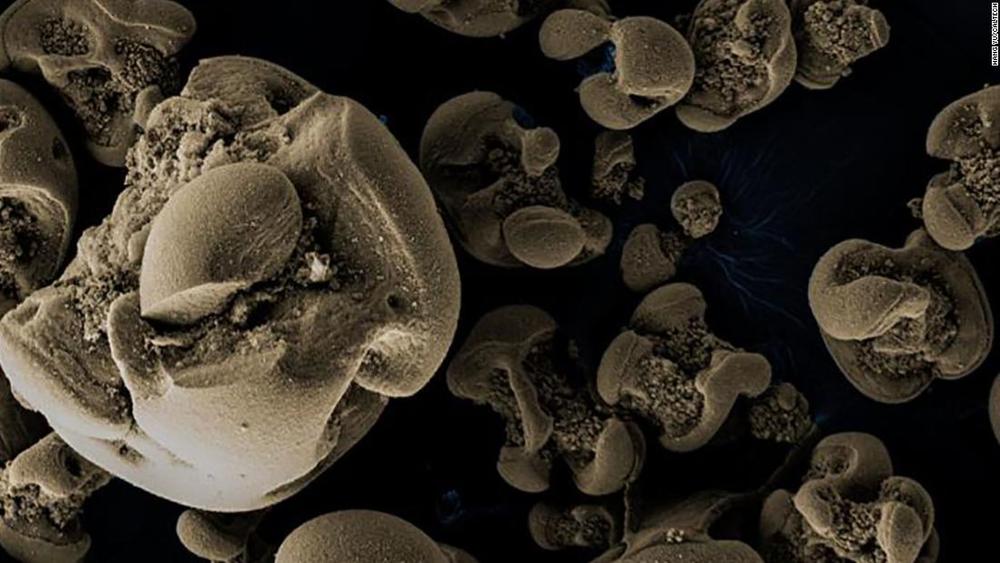

When I think of KFC and its largely unchanging menu of fried chicken, I do not immediately think of innovation. However a new collaboration forged between the fast-food company and Russia-based bioprinting firm 3D Bioprinting Solutions might just change my mind. The partners are working together to develop the world’s first laboratory-produced chicken nuggets. The 3D printed nuggets are expected to be similar in taste and appearance to KFC’s original product, but will have the benefit of being more environmentally friendly to produce.

The bioprinted chicken nugget project is already underway, and the unlikely partners plan to have a final product ready for testing by this fall. The effort is part of KFC’s mission to create a “restaurant of the future” which leverages state-of-the-art technologies like 3D bioprinting to overcome solutions in the food industry today: such as finding more eco-friendly alternatives to traditional meat.

“At KFC, we are closely monitoring all of the latest trends and innovations and doing our best to keep up with the times by introducing advanced technologies to our restaurant networks,” said Raisa Polyakova, General Manager of KFC Russia & CIS. “Crafted meat products are the next step in the development of our “restaurant of the future” concept. Our experiment in testing 3D bioprinting technology to create chicken products can also help address several looming global problems. We are glad to contribute to its development and are working to make it available to thousands of people in Russia and, if possible, around the world.”