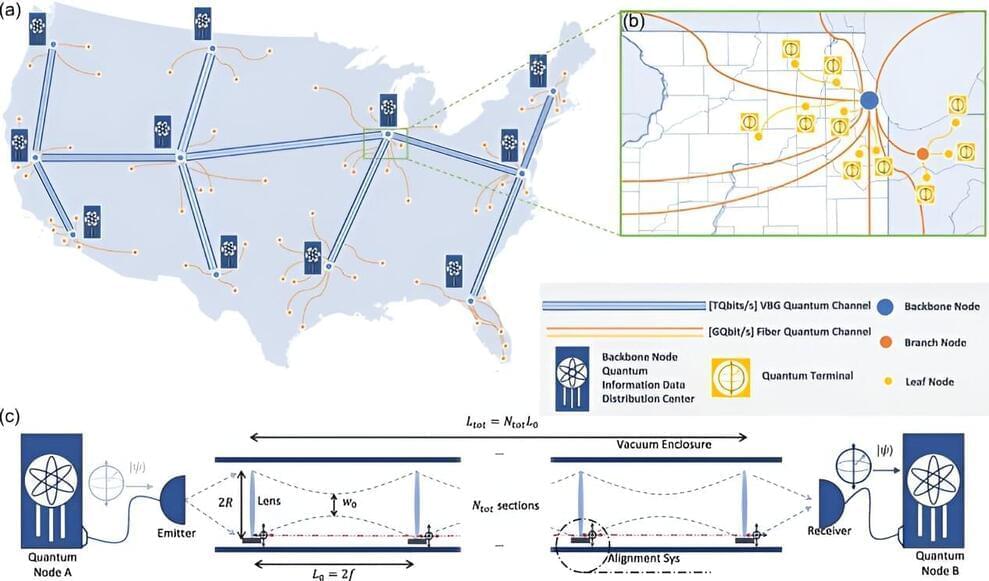

Quantum computers offer powerful ways to improve cybersecurity, communications, and data processing, among other fields. To realize these full benefits, however, multiple quantum computers must be connected to build quantum networks or a quantum internet. Scientists have struggled to come up with practical methods of building such networks, which must transmit quantum information over long distances.

Now, researchers at the University of Chicago Pritzker School of Molecular Engineering (PME) have proposed a new approach—building long quantum channels using vacuum sealed tubes with an array of spaced-out lenses. These vacuum beam guides, about 20 centimeters in diameter, would have ranges of thousands of kilometers and capacities of more than 1,013 qubits per second, better than any existing quantum communication approach. Photons of light encoding quantum data would move through the vacuum tubes and remain focused thanks to the lenses.

“We believe this kind of network is feasible and has a lot of potential,” said Liang Jiang, professor of molecular engineering and senior author of the new work. “It could not only be used for secure communication, but also for building distributed quantum computing networks, distributed quantum sensing technologies, new kinds of telescopes, and synchronized clocks.”