A new “atlas” developed by researchers at Duke University School of Medicine, University of Tennessee Health Science Center, and the University of Pittsburgh will increase precision in measuring changes in brain structure and make it easier to share results for scientists working to understand neurological diseases such as Alzheimer’s disease.

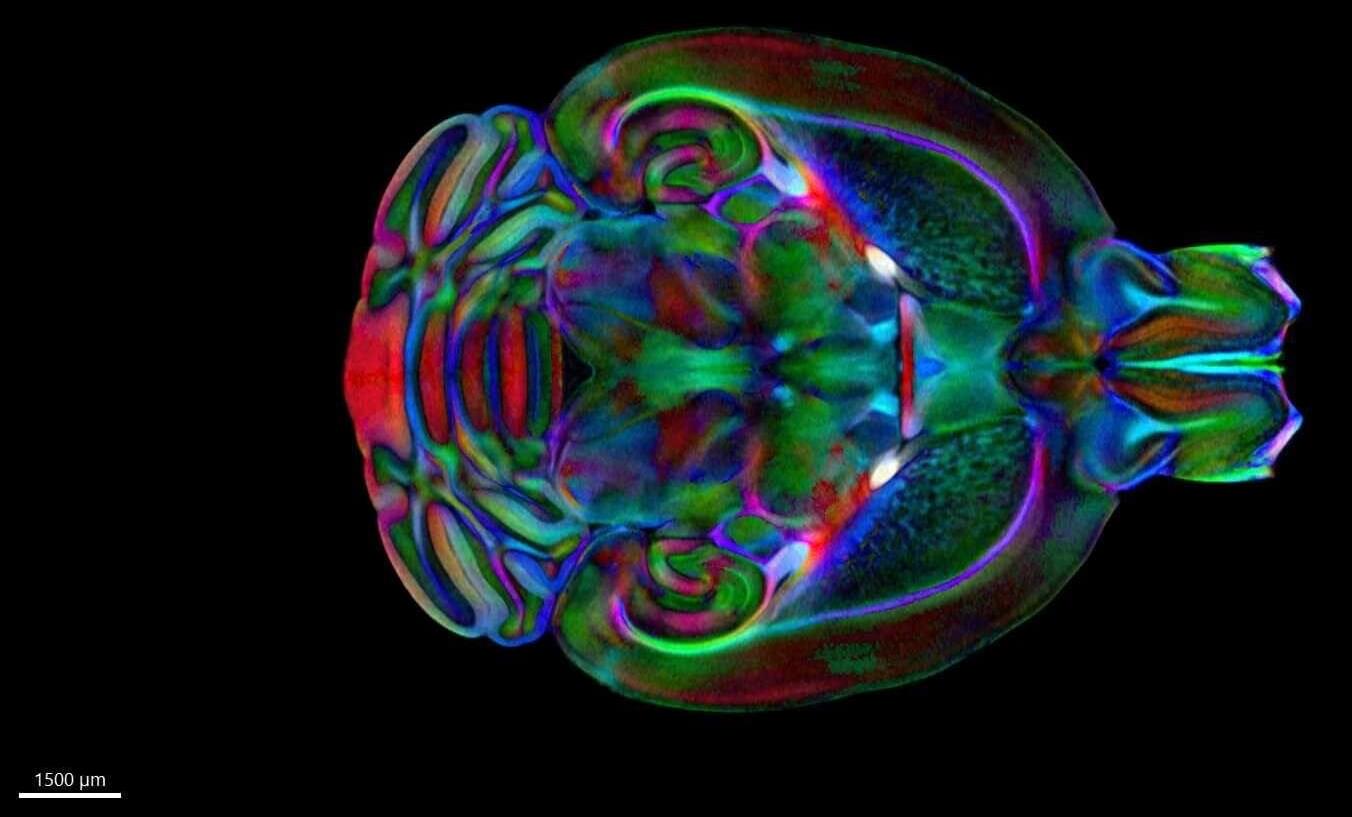

The tool, the Duke Mouse Brain Atlas, combines microscopic resolution, three-dimensional images from three different techniques to create a detailed map of the entire mouse brain, from large structures down to individual cells and circuits.

“This is the first truly three-dimensional, stereotaxic atlas of the mouse brain,” said G. Allan Johnson, Ph.D., Charles E. Putman University Distinguished Professor of Radiology at Duke. He is also professor in the Department of Physics and the Department of Biomedical Engineering.