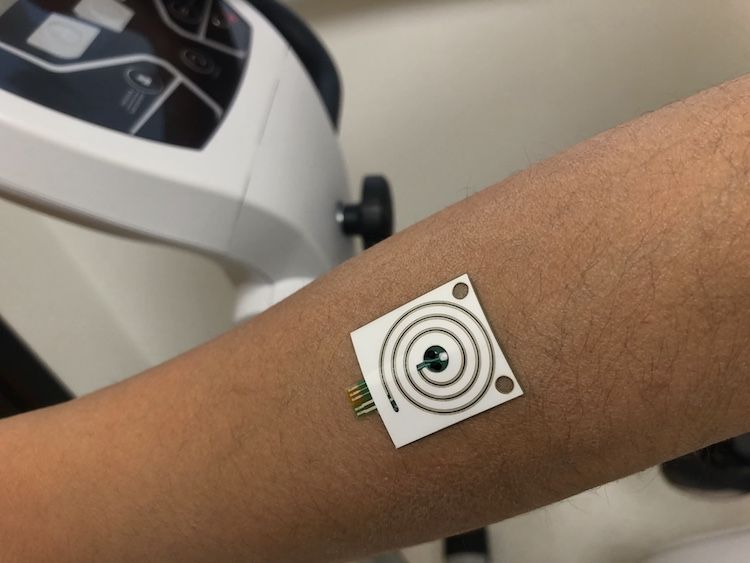

Cambridge engineers have developed a new augmented reality (AR) head mounted display (HMD) that delivers a realistic 3D viewing experience, without the commonly associated side effects of nausea or eyestrain.

The device has an enlarged eye-box that is scalable and an increased field of view of 36º that is designed for a comfortable viewing experience. It displays images on the retina using pixel beam scanning which ensures the image stays in focus regardless of the distance that the user is fixating on. Details are reported in the journal Research.

Developed by researchers at the Centre for Advanced Photonics and Electronics (CAPE) in collaboration with Huawei European Research Centre, in Munich, the HMD uses partially reflective beam splitters to form an additional “exit pupil” (a virtual opening through which light travels). This, together with narrow pixel beams that travel parallel to each other, and which do not disperse in other directions, produces a high quality image that remains unaffected by changes in eye focus.