Binding reagents may lower error rate compared to sequencing by synthesis by.

Laurel Oldach

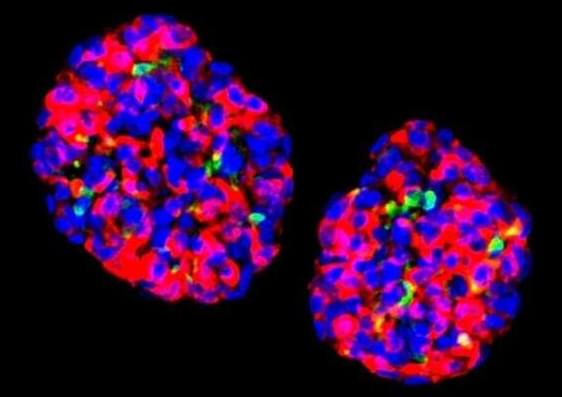

Scientists have repurposed human stomach cells into tissues that release insulin in response to rising blood sugar levels in a breakthrough that promises an effective way to manage conditions such as type 1 diabetes.

The experiment, led by researchers from Weill Cornell Medicine in the US, revealed transplants of gastric insulin-secreting (GINS) cells reversed diabetes in mice.

Pancreatic beta cells normally do the job of releasing the hormone insulin in response to elevated sugar levels in the blood. In people with diabetes, these tissues are damaged or die off, compromising their ability to move glucose into cells for fuel.

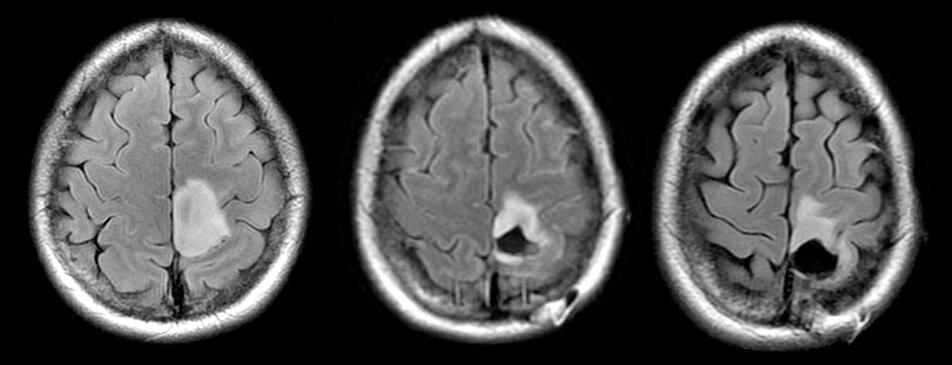

Mindfulness-based awareness training can help people learn to better control brain-computer interfaces. But a new study has found that a single guided mindfulness meditation exercise isn’t enough to boost performance. The findings, published in Frontiers in Human Neuroscience, suggest that a longer period of meditation is needed in order for people to experience observable improvements.

The authors of the research are interested in exploring the potential benefits of using mindfulness meditation as a training tool to improve the performance of brain-computer interfaces, which allow individuals to control machines or computers directly from their brain, bypassing the traditional neuromuscular pathway. These devices have the potential to greatly benefit people with conditions such as spinal cord injuries, stroke, and neurodegenerative diseases like amyotrophic lateral sclerosis (ALS).

Previous studies have shown that one of the most effective signals for brain-computer interface control is the sensorimotor rhythm produced in the primary sensorimotor areas during motor imagery. However, not everyone is able to effectively control brain-computer interfaces, with approximately 20% of the population being “BCI-inefficient” even with extensive training. Therefore, researchers are looking for ways to improve performance, and one potential method is through meditation.

Join us on Patreon! https://www.patreon.com/MichaelLustgartenPhD

Discount Links:

NAD+ Quantification: https://www.jinfiniti.com/intracellular-nad-test/

Use Code: ConquerAging At Checkout.

Epigenetic Testing: https://trudiagnostic.com/?irclickid=U-s3Ii2r7xyIU-LSYLyQdQ6…M0&irgwc=1

Use Code: CONQUERAGING

At-Home Blood Testing: https://getquantify.io/mlustgarten.

Oral Microbiome: https://www.bristlehealth.com/?ref=michaellustgarten.

Enter Code: ConquerAging.

Green Tea: https://www.ochaandco.com/?ref=conqueraging.

Neuralink Corp. has been cleared by the FDA to start human trials for its medical technology — and there’s no shortage of potential volunteers.

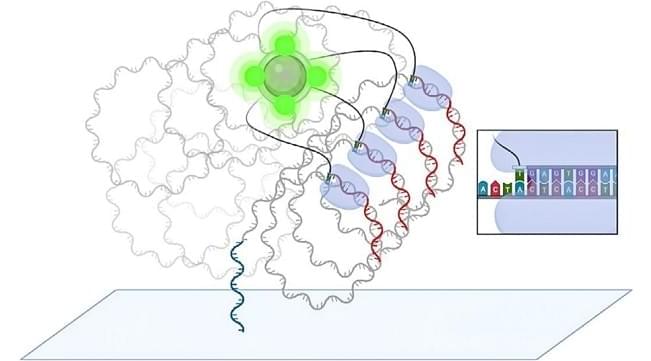

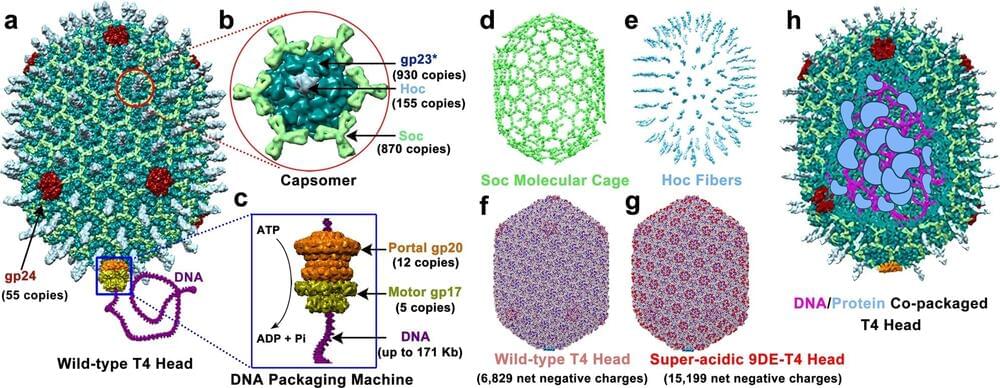

A team of medical scientists at The Catholic University of America, in Washington, D.C., working with a colleague from Purdue University, has developed a way to engineer the bacteriophage T4 to serve as a vector for molecular repair. The study is reported in the journal Nature Communications.

Prior research has shown that many human ailments arise due to genetic mutations: cystic fibrosis, Down syndrome, sickle cell disease and hemophilia are just a few. Logic suggests that correcting such genetic mutations could cure these diseases. So researchers have been working toward developing gene editing tools that will allow for safe editing of genes.

One of the most promising is the CRISPR gene editing system. In this new effort, the research team took a more general approach to solving the problem by working to develop a vector that could be used to carry different kinds of tools to targeted cells and then enter them to allow for healing work to commence.