Circa 2020

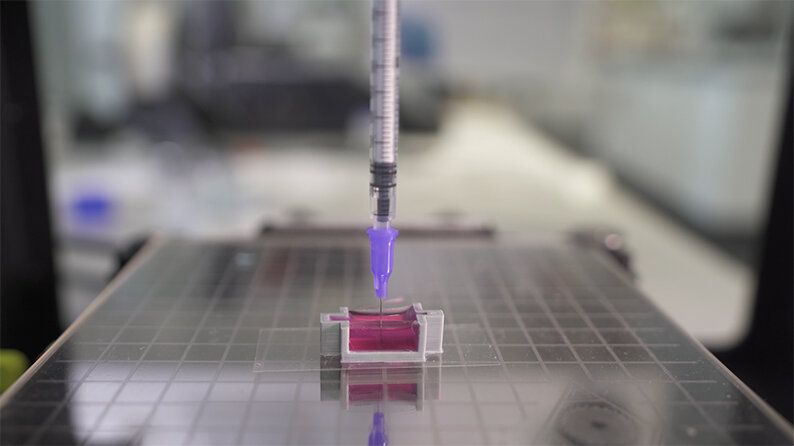

The FRESH technique of 3D bioprinting was invented in Feinberg’s lab to fill an unfilled demand for 3D printed soft polymers, which lack the rigidity to stand unsupported as in a normal print. FRESH 3D printing uses a needle to inject bioink into a bath of soft hydrogel, which supports the object as it prints. Once finished, a simple application of heat causes the hydrogel to melt away, leaving only the 3D bioprinted object.

While Feinberg, a professor of biomedical engineering and materials science and engineering, has proven both the versatility and the fidelity of the FRESH technique, the major obstacle to achieving this milestone was printing a human heart at full scale. This necessitated the building of a new 3D printer custom made to hold a gel support bath large enough to print at the desired size, as well as minor software changes to maintain the speed and fidelity of the print.