Modular, 3D printed or skintight, the new space suits for life on Mars need to be comfortable and fiercely protective of the human inside.

3D printed models of dog skulls are helping University of Queensland vets to save animals and educate tomorrow’s veterinary students.

The models, showcased at the World Science Festival, were the result of a collaboration between UQ Library’s Digital Scholars Hub and the School of Veterinary Science.

UQ veterinarian and Associate Professor Rachel Allavena used the skulls to help children understand how dogs with short noses can suffer from the condition brachycephalia.

With the rise of enhanced being the world will change at a fast pace similar games such as black ops 3 are a proper representation of possible outcomes in warfare. Like for instance sentient warfighting robot beings or cybernetically enhanced humans. The extremes of these also are seen in wetware which can essentially not have many limits so increased strength intelligence really anything you can imagine. Really sci-fi games such as halo are not far off at the possibilities of warfare. Really we are only limited by our imagination.

The author of “Ghost Fleet” has some guesses — and some questions that U.S. defenders will have to answer.

Robots, artificial intelligence, cyberwar, 3D printing, bio-enhancements, and a new geopolitical competition; the 21st century is being shaped by a range of momentous, and scary, new trends and technologies. We should also expect them to shape the worlds of insurgency and terrorism.

With so much change, it is too early to know all that will shake out from these new technologies in the years leading toward 2030 and beyond. But we can identify a few key trends of what will matter for war and beyond, and resulting questions that future counter-insurgents will likely have to wrestle with. Below are three, pulled from a recent New America report on what the tech and wars of 2030 might portend.

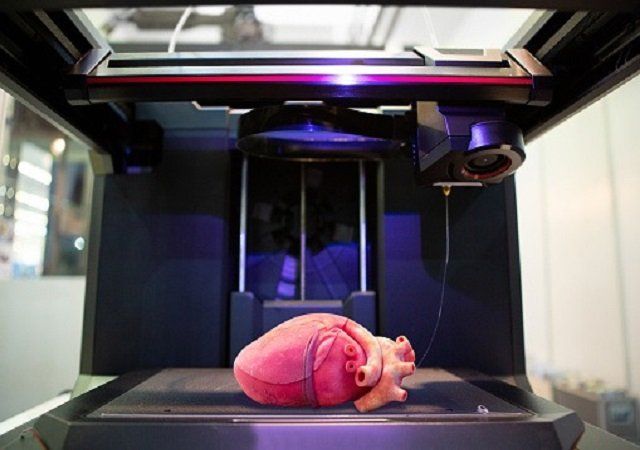

We’re tantalizingly close to growing organs in the lab, but the biggest remaining challenge has been creating the fine networks of blood vessels required to keep them alive. Now researchers have shown that a common food dye could solve the problem.

In the US there are currently more than 100,000 people on organ transplant waiting lists. Even if you’re lucky enough to receive a replacement, you face a lifetime on immunosuppressant drugs. That’s why scientists have long dreamed of growing new organs from patients’ own cells, which could simultaneously tackle the shortage and the risk of organ rejection.

The field of tissue engineering has seen plenty of progress. Lab-grown skin has been medically available for decades, and more recently stem cells have been used to seed scaffolds—either built form synthetic materials or made by stripping cells from natural support structures—to reproduce more complex biological tissue.

3D printing is moving ever closer to gaining a true home in mainstream commercial applications, thanks to the impact the technology is having on consumer fashion products such as jewelry, footwear, and clothing. While 3D printed fashion was still considered to be more of a novelty a few years ago, efforts have been increasing to make it more common – even in the classroom. Additionally, the technology is helping to usher in a more sustainable and eco-friendly way of manufacturing garments…and designer Julia Daviy is helping to lead the charge.

3D printing is moving ever closer to gaining a true home in mainstream commercial applications, thanks to the impact the technology is having on consumer fashion products such as jewelry, footwear, and clothing. While 3D printed fashion was still considered to be more of a novelty a few years ago, efforts have been increasing to make it more common – even in the classroom. Additionally, the technology is helping to usher in a more sustainable and eco-friendly way of manufacturing garments…and designer Julia Daviy is helping to lead the charge.

In addition to designing clothes, Daviy is also an ecologist and clean technology industry manager, and uses 3D printing to make cruelty-free, zero-waste clothing. She believes that the technology will change how the world produces clothing, especially when it comes to some of the more problematic issues of garment manufacturing, such as animal exploitation, chemical pollution, energy consumption, and material waste.

“Our goal was never to demonstrate the viability of 3D printed clothing and leave things at that. We’ll have succeeded when beautiful, comfortable, ethically manufactured and environmentally friendly clothes are the standard,” Daviy stated. “The innovations we’ve made on the production and marketing side of the equation are just as important as the technological breakthroughs that have gotten us this far.”

Up-and-coming fashion designer Ganit Goldstein may not have had her 3D printed wearables on display at the recent Met Gala (where Zac Posen became the latest designer to use 3D printing in his work), but her designs are striking nonetheless. Her most recent collection, Shifted Craft, was debuted at Milan Design Week last month.

Goldstein prides herself as a fashion designer working at the intersection of craft and technology. This means she frequently combines new technologies, such as 3D scanning, modeling and printing with more traditional textile and garment-making practices. Shifted Craft, which comprises seven pieces of jewelry and two pairs of shoes, embodies these overlapping approaches seamlessly and stylishly.

“One of the biggest roadblocks to generating functional tissue replacements has been our inability to print the complex vasculature that can supply nutrients to densely populated tissues,” said Jordan Miller, assistant professor at Rice University in the US.

“Further, our organs actually contain independent vascular networks — like the airways and blood vessels of the lung or the bile ducts and blood vessels in the liver,” Miller said.

“These interpenetrating networks are physically and biochemically entangled, and the architecture itself is intimately related to tissue function. Ours is the first bioprinting technology that addresses the challenge of multi vascularisation in a direct and comprehensive way,” he said.

A few years ago, a friend and fellow author Manu Saadia (author of Trekonomics: The Economics of Star Trek) posed a question to me about the viability of creating actual cities on other planets. It was, in his mind, one of the few things about Star Trek which seemed unrealistic, because of the fact that cities here on Earth thrive due to one important reason: imports/exports, i.e. resource exchange.

As we continue planning ahead for the future of both space travel and space colonization, the need for advanced 3D printing will ultimately dictate our ability to maintain viable civilizations on other planets.