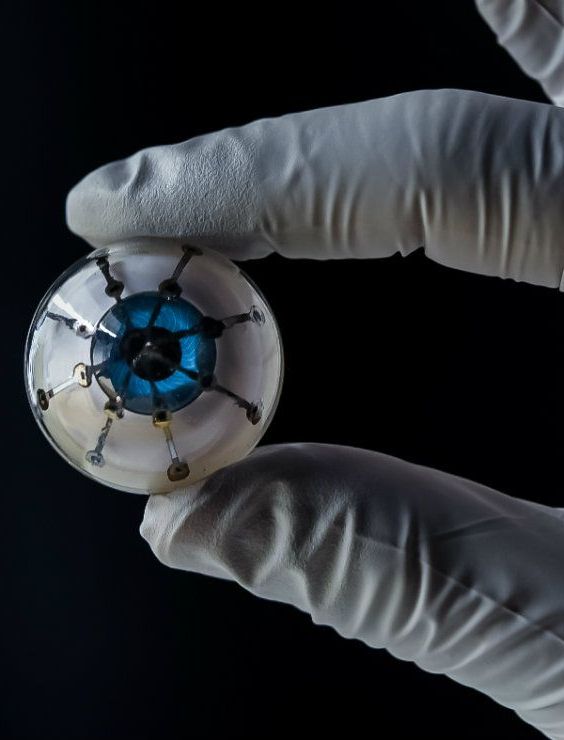

#Technology in #medicine: What will the #future #healthcare be like? https://www.neurozo-innovation.com/post/future-health Technologies have made many great impacts on our medical system in recent years. The article will first give a thorough summarization of them, and then the expectations and potential problems regarding future healthcare will be discussed. #AI #5G #VR #AR #MR #3DPrinting #BrainComputerInterface #telemedicine #nanotechnology #drones #SelfDriving #blockchain #robotics #innovation #trend

Technology has many beneficial effects on modern people’s lives, and one of them is to prolong our lifespan through advancing the medical field. In the past few years, new techniques such as artificial intelligence, robots, wearable tech, and so on have been used to improve the quality of our healthcare system, and some even newer innovations such as flying vehicles and brain computer interface are also considered valuable to the field. In this article, we will first give a thorough discussion about how these new technologies will shape our future healthcare, and then some upcoming problems that we may soon face will be addressed.