As of this month, over 4,000 Americans are on the waiting list to receive a heart transplant. With failing hearts, these patients have no other options; heart tissue, unlike other parts of the body, is unable to heal itself once it is damaged. Fortunately, recent work by a group at Carnegie Mellon could one day lead to a world in which transplants are no longer necessary to repair damaged organs.

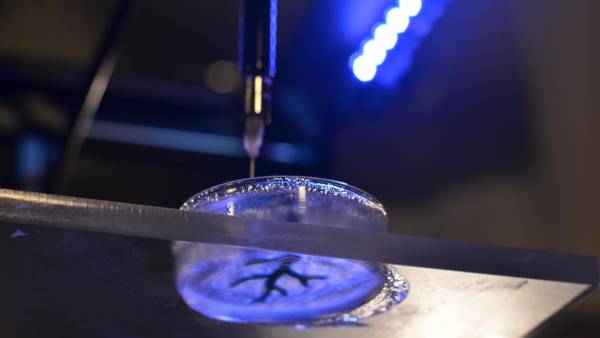

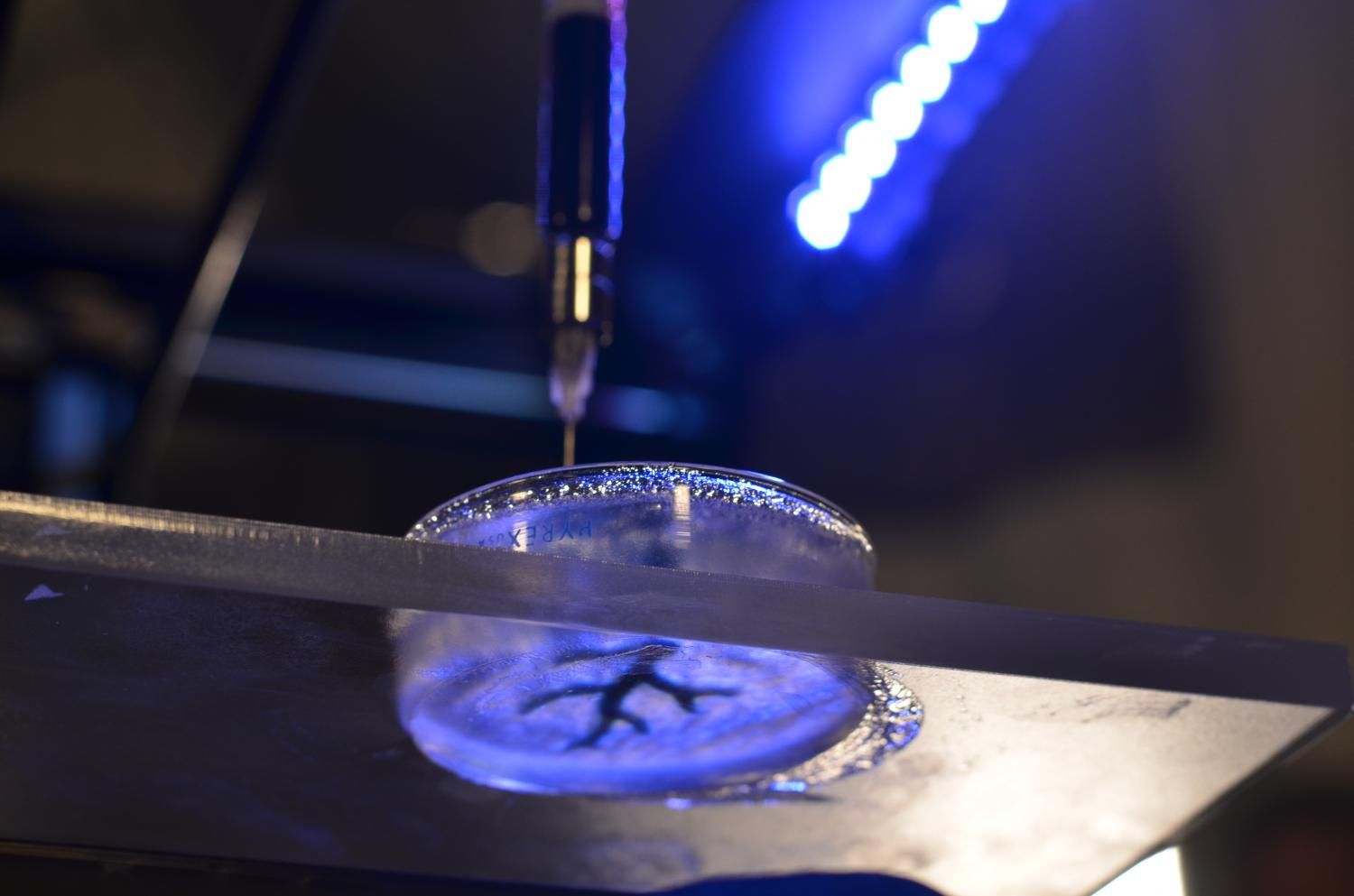

“We’ve been able to take MRI images of coronary arteries and 3-D images of embryonic hearts and 3-D bioprint them with unprecedented resolution and quality out of very soft materials like collagens, alginates and fibrins,” said Adam Feinberg, an associate professor of Materials Science and Engineering and Biomedical Engineering at Carnegie Mellon University. Feinberg leads the Regenerative Biomaterials and Therapeutics Group, and the group’s study was published in the October 23 issue of the journal Science Advances. A demonstration of the technology can be seen below.

“As excellently demonstrated by Professor Feinberg’s work in bioprinting, our CMU researchers continue to develop novel solutions like this for problems that can have a transformational effect on society,” said Jim Garrett, Dean of Carnegie Mellon’s College of Engineering. “We should expect to see 3-D bioprinting continue to grow as an important tool for a large number of medical applications.”

Read more