New spacecraft experience setbacks all the time. SpaceX Starship prototype violently disassembled several times. Boeing launched the CST-100 but ended up in the wrong orbit. China isn’t a stranger to setbacks either.

China tested a prototype spacecraft on May 5th, 2020 in efforts to prove the technology was ready. It’s good it was a test and not an actual mission since the spacecraft did not perform as expected. The news agency Xinhua reported the spacecraft launched from Hainan China, operated abnormally during its return.

Heat Shields Need to work or expect a terrible day.

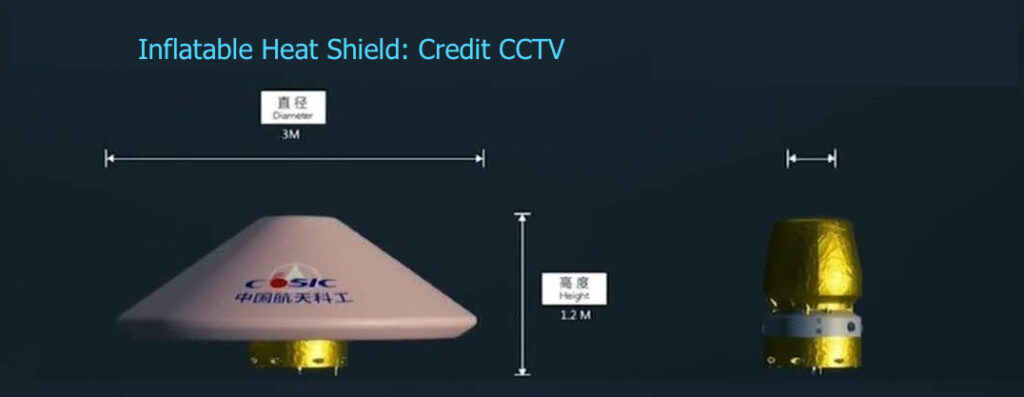

Spacecraft experience tremendous heat during the last minutes of their mission. The heat shield protects the spacecraft from that heat. NASA looked at lots of materials and tested many before using for heat shields.