O,.o.

AMD has patented Infinity Cache, lending credence to the rumors of its existence.

Harworth Group plc has announced the completion of the UK Atomic Energy Authority’s (UKAEA’s) new nuclear fusion technology research facility at the Advanced Manufacturing Park in Rotherham, South Yorkshire. When it opens later this year, the 2500-square-metre facility will develop and test joining technologies for fusion materials and components, including novel metals and ceramics.

Property developer Harworth said completion of the GBP22 million (USD28 million) Fusion Technology facility triggers UKAEA’s 20-year lease with Harworth at a rent in line with other manufacturers at the Advanced Manufacturing Park. UKAEA will now prepare the building prior to taking formal occupation of it later this year.

The new facility is being funded as part of the government’s Nuclear Sector Deal delivered through the Department for Business, Energy and Industrial Strategy. An additional GBP2 million of investment came from Sheffield City Region’s Local Growth Fund.

Circa 2017

Quantum computing is the next big technological revolution, and it’s coming sooner than you might think. IBM unveiled its own quantum processor this past May, scientists have been experimenting with silicon-laced diamonds (and basic silicon, too) as a quantum computing substrate, Google is already looking at cloud-based solutions and Microsoft is already creating a new coding language for the technology. Now Intel has taken another big step towards a quantum computing reality: the company has created a new superconducting chip using advanced material science and manufacturing techniques, and delivered it to Intel’s research partner in the Netherlands, QuTech.

O,.o.

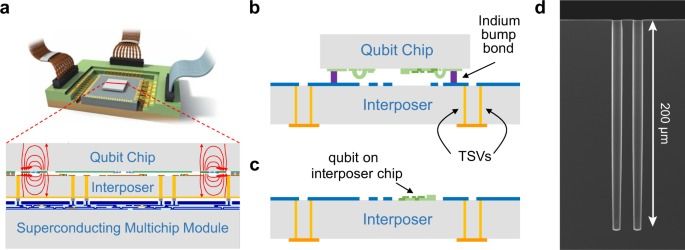

As superconducting qubit circuits become more complex, addressing a large array of qubits becomes a challenging engineering problem. Dense arrays of qubits benefit from, and may require, access via the third dimension to alleviate interconnect crowding. Through-silicon vias (TSVs) represent a promising approach to three-dimensional (3D) integration in superconducting qubit arrays—provided they are compact enough to support densely-packed qubit systems without compromising qubit performance or low-loss signal and control routing. In this work, we demonstrate the integration of superconducting, high-aspect ratio TSVs—10 μm wide by 20 μm long by 200 μm deep—with superconducting qubits. We utilize TSVs for baseband control and high-fidelity microwave readout of qubits using a two-chip, bump-bonded architecture. We also validate the fabrication of qubits directly upon the surface of a TSV-integrated chip. These key 3D-integration milestones pave the way for the control and readout of high-density superconducting qubit arrays using superconducting TSVs.

At 870 degrees Fahrenheit and 90 times Earth’s atmospheric pressure, we’re going to need something a little more robust than your Macbook to run future rovers.

Humanity has sent four rovers to Mars, and worldwide there are four more missions in the works to continue populating the red planet with robotic explorers. Why haven’t we sent a rover to Venus, our other next door planetary neighbor? Because the caustic surface of Venus will incinerate electronics with its 872º F temperatures and seize mechanical components with its immense atmospheric pressures. At 90 times the surface pressure of Earth, the surface of Venus is the equivalent of being almost 3,000 feet underwater.

The Great Galactic Ghoul might devour half the spacecraft we send to Mars, but Venus torched any ghouls living there long ago.

Fortunately, NASA recently took a big step toward achieving the dream of a Venusian rover. As reported by Ars Technica, researchers at the NASA Glenn Research Center built a computer chip that survived Venus-like conditions for an impressive 521 hours, almost 22 days. Even then, the experiment had to end not because the chip was breaking down, but because the Glenn Extreme Environments Rig (GEER) —the chamber that maintains simulated Venus temperatures and pressures—needed to be shut down after running for over three weeks straight.

Astrobiology students cultivated leafy greens, sweet potatoes, and even hops in simulated Martian dirt.

NASA and private entrepreneurs are pushing to land people on Mars within the next generation. To survive on Mars, colonists will need a lot of gear, not least of which is food. Since lugging food adds a lot of weight to spacecraft — and packaged food only retains its nutrients for so long, anyway — any would-be Martians will need to grow food on site in order to survive.

But conditions on the Red Planet are different than on Earth. The surface receives less than half the amount of sunlight that Earth does, and dust in the atmosphere can attenuate it even more. Due to the absence of an ozone layer, more ultraviolet radiation reaches the ground. As to the Martian surface itself, the dirt (technically “regolith”) is more iron-rich, particularly in iron oxides.

The next decade is going to be a transforming decade as many many technologies (some of which we all like to share in this group) are converging and maturing enough to rearrange our society in almost any aspect we can conceive.

I’m calling to those who are interested in creating and implementing an alternative model for the current social and governance systems, let’s build an open state that we can all support and trust regardless of our age, sex, geographical location, or belief system.

In the next 10 years, key technologies will converge to completely disrupt the five foundational sectors—information, energy, food, transportation, and materials—that underpin our global economy. We need to make sure the disruption benefits everyone.

Today we catch up on all the latest Starship and Super Heavy updates. Go over recent Dragon news. Talk Starlink and other upcoming missions, and finish with today’s Honorable Mention.

SUBSCRIBE: https://www.youtube.com/spacexcentric

BECOME AN XCENTRIC MEMBER: https://www.youtube.com/spacexcentric/join

SUPPORT ON PATREON: https://www.patreon.com/spaceXcentric

JOIN OUR DISCORD: https://discord.gg/UCv4yx4

WEBSITE: https://spacexcentric.com

Does this make you feel uncomfortable?? Take a look at the tech 🤩 in this truck! Mercedes-Benz truck of the future…thoughts?