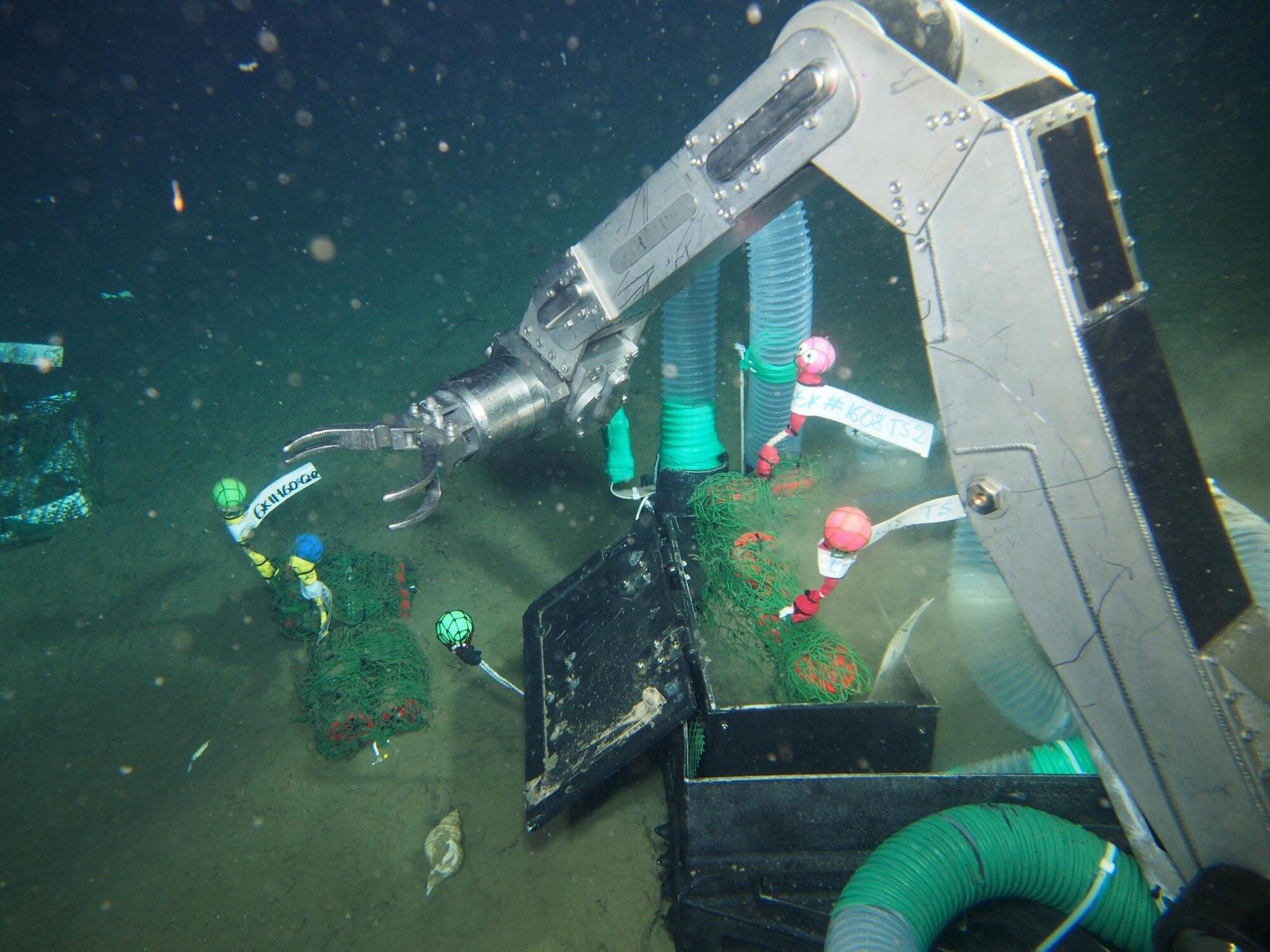

Animals like bats, whales and insects have long used acoustic signals for communication and navigation. Now, an international team of scientists has taken a page from nature’s playbook to model micro-sized robots that use sound waves to coordinate into large swarms that exhibit intelligent-like behavior.

The robot groups could one day carry out complex tasks like exploring disaster zones, cleaning up pollution, or performing medical treatments from inside the body, according to team lead Igor Aronson, Huck Chair Professor of Biomedical Engineering, Chemistry, and Mathematics at Penn State.

“Picture swarms of bees or midges,” Aronson said. “They move, that creates sound, and the sound keeps them cohesive, many individuals acting as one.”