This engine will let us stay there for months, if not years.

Could the key to interstellar exploration be a nuclear-powered flyer that circles Jupiter?

Lightmatter bets that optical computing can solve AI’s efficiency problem.

In a study published in Physical Review Letters, a team led by academician Guo Guangcan from the University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS) has made progress in high dimensional quantum teleportation. The researchers demonstrated the teleportation of high-dimensional states in a three-dimensional six-photon system.

To transmit unknown quantum states from one location to another, quantum teleportation is one of the key technologies to realize long-distance transmission.

Compared with two-dimensional systems, high-dimensional system quantum networks have the advantages of higher channel capacity and better security. In recent years more and more researchers of the quantum information field have been working on generating efficient generation of high-dimensional quantum teleportation to achieve efficient high-dimensional quantum networks.

Elon Musk’s Neuralink has a straightforward outlook on artificial intelligence: “If you can’t beat em, join em.” The company means that quite literally — it’s building a device that aims to connect our brains with electronics, which would enable us, in theory, to control computers with our thoughts.

But how? What material would companies like Neuralink use to connect electronics with human tissue?

One potential solution was recently revealed at the American Chemical Society’s Fall 2020 Virtual Meeting & Expo. A team of researchers from the University of Delaware presented a new biocompatible polymer coating that could help devices better fuse with the brain.

Mercedes’ new AI screen is extremely wide! Check out how it could up the stakes against Tesla.

Deep learning has come a long way since the days when it could only recognize handwritten characters on checks and envelopes. Today, deep neural networks have become a key component of many computer vision applications, from photo and video editors to medical software and self-driving cars.

Roughly fashioned after the structure of the brain, neural networks have come closer to seeing the world as humans do. But they still have a long way to go, and they make mistakes in situations where humans would never err.

These situations, generally known as adversarial examples, change the behavior of an AI model in befuddling ways. Adversarial machine learning is one of the greatest challenges of current artificial intelligence systems. They can lead to machine learning models failing in unpredictable ways or becoming vulnerable to cyberattacks.

O,.o circa 2020.

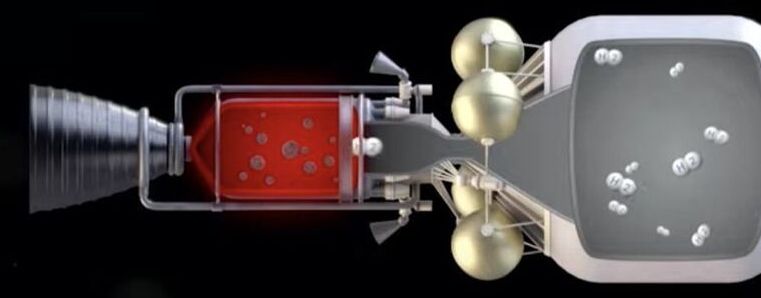

Their quantum phase battery consists of an n-doped InAs nanowire forming the core of the battery (the pile) and Al superconducting leads as poles. It is charged by applying an external magnetic field, which then can be switched off.

Cristina Sanz-Fernández and Claudio Guarcello, also from CFM, adapted the theory to simulate the experimental findings.

The battery is being further developed and improved at CFM premises in a collaboration between the Nanophysics Lab and the Mesoscopic Physics Group. These advances could contribute to enormous advances that many say will come from the field of quantum computing.