Graphics chip maker Nvidia is urging users to install new security updates that address one high-severity flaw and four others that can be exploited by attackers.

Quinn Sena to Lifeboat Foundation

Posted in lifeboat

The future could be here before we know it. On Monday, Fisker Inc.—the company behind the Tesla Model S-fighting EMotion picture above—announced that it had filed patents for a new type of battery technology that could put electric cars with 500-plus mile ranges and one-minute recharging times on the roads as soon as the year 2024.

While Fisker’s press release was, unsurprisingly, a tad cagey about the details of this potentially paradigm-shattering technology, the company did reveal a few bits about what its new inventions and discoveries could do. Fisker’s new power storage technology, according to the company, would allow it to build solid-state batteries packing far more surface area than existing flat thin-film solid-state electrodes can do, while also allowing for greater conductivity, allowing the batteries to work better in cold weather and charge faster overall. (Low levels of conductivity has been one of the key problems preventing the widespread adoption of solid-state batteries so far, so this could potentially be, as Michael Scott might say, a B.F.D.)

Due to the complexities of bringing the new technology to market, such as developing supply chains for some raw materials and setting up property quality control measures for them, Fisker says the technology isn’t likely to reach cars and trucks until sometime after 2023. Once it does, however, the company claims the batteries—2.5 times more power-dense than their lithium ion equivalents—could lead to electric vehicles capable of recharging in less time than it takes to fill a modern car’s gas tank, then driving more than 500 miles before needing to power up again. Oh, and the carmaker says the batteries would cost about one-third as much as li-ion ones, to boot. (That said, Fisker did mention that there are still plenty of “technical bottlenecks” between where the tech is now and where it needs to be for production use, so don’t get too excited just yet.)

THE reaction synchronous motor in its present form (salient-pole rotor without field coils) is one of the oldest types of electric motors, antedating the i.

Application filed by Klaus L Hansen

Posted in futurism

Dec. 23, 1952 K. L. HANSEN 2,623,201

SYNCHRONOUS MOTOR Filed Aug. 5, 1950 s Sheets-Sheet 1 1 A0/d577i645 l i A? AZ v fl/Z INVEN TOR. M 13 Z. 351151 1? 2 m WWW; filth/way Dec. 23, 1952 K. L. HANSEN 2,623,201.

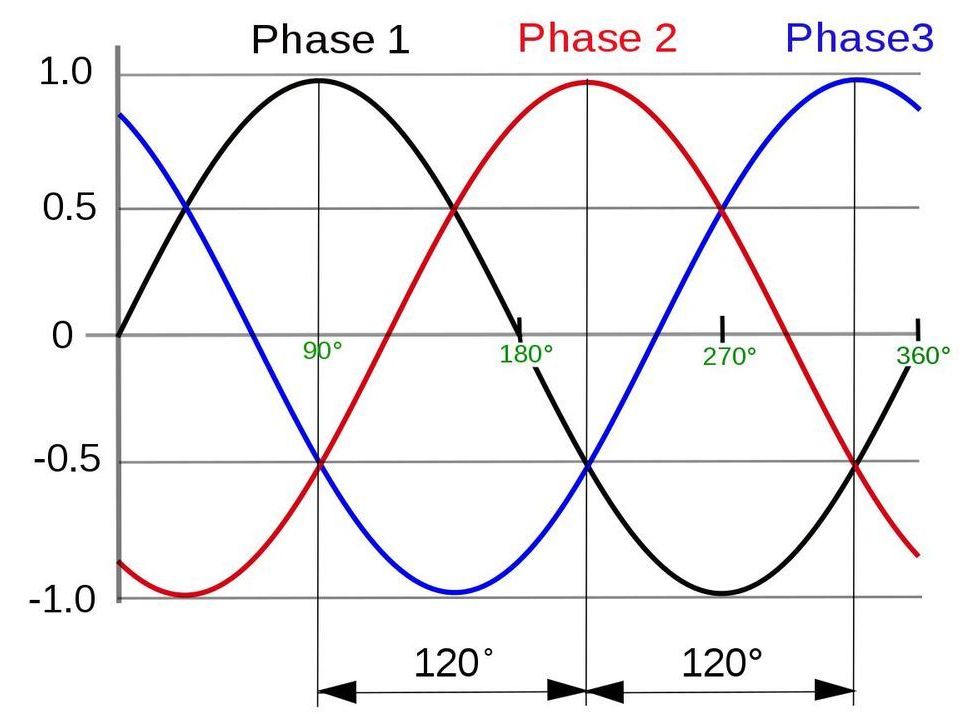

Polyphase system

Posted in energy

A polyphase system is a means of distributing alternating-current electrical power where the power transfer is constant during each electrical cycle. Polyphase systems have three or more energized electrical conductors carrying alternating currents with a defined phase angle between the voltage waves in each conductor; for three-phase voltage, the phase angle is 120° or ~2.09 radians. Polyphase systems are particularly useful for transmitting power to electric motors which rely on alternating current to rotate. The most common example is the three-phase power system used for industrial applications and for power transmission. Compared to a single-phase, two-wire system, a three-phase three-wire system transmits three times as much power for the same conductor size and voltage.

Systems with more than three phases are often used for rectifier and power conversion systems, and have been studied for power transmission.

Tesla Polyphase Induction Motors

Posted in futurism

Most AC motors are induction motors. Induction motors are favored due to their ruggedness and simplicity. In fact, 90% of industrial motors are induction motors.

Nikola Tesla conceived the basic principles of the polyphase induction motor in 1883 and had a half horsepower (400 watts) model by 1888. Tesla sold the manufacturing rights to George Westinghouse for $65,000.

Most large ( 1 hp or 1 kW) industrial motors are polyphase induction motors. By polyphase, we mean that the stator contains multiple distinct windings per motor pole, driven by corresponding time-shifted sine waves. In practice, this is two or three phases. Large industrial motors are 3-phase. While we include numerous illustrations of two-phase motors for simplicity, we must emphasize that nearly all polyphase motors are three-phase. By induction motor, we mean that the stator windings induce a current flow in the rotor conductors, like a transformer, unlike a brushed DC commutator motor.

BU researchers have discovered specialized brain cells that provide rats—and most likely, humans— with personalized maps of their surroundings, helping them navigate through obstacles. The findings could lead to improved autonomous vehicles that can navigate unpredictable and dynamic terrain.

In the last week alone, SpaceX’s twin orbital Starship prototypes have made some truly jaw-dropping progress. Onlookers have witnessed Florida’s Starship push through a rapid growth spurt, while the company’s Texas team has begun to install propellant tank bulkheads and work on a triple-Raptor thrust structure.

Meanwhile, SpaceX CEO Elon Musk has suggested that one or both of the orbital-class Starship prototypes could be “almost ready to fly” by August 24th, the date of the CEO’s next official update on Starship (formerly BFR and ITS). Although the actual challenge of building a massive, orbital-class launch vehicle is far subtler than the visible steelwork needed to build its primary structure and pressure vessels, the veritable leaps forward made in both Texas and Florida in the last 7–10 days are extremely encouraging signs.

Starting off in Boca Chica, Texas, SpaceX’s team of engineers and technicians have been simultaneously handling Starhopper’s first untethered flight test (completed on July 25th) and building the facility’s orbital-class Starship prototype. Most significantly, after a few days of preparation, what is likely the Texas Starship’s first bulkhead was lowered inside its ~25m-tall (80 ft) barrel section, composed of the spacecraft’s propulsion section and propellant tanks.

KALISPELL, Mont. — Two middle schoolers in the Flathead are making a name for themselves in the robotics world. Katie Eberhardy and Jessie Chadwick recently won the regional, NASA-sponsored Apollo Next Great Leap Student Challenge.

Eberhardy and Chadwick’s team—the Lunar Loonies—was the only all-girl team in the competition, and one of the smallest of the about 20 other teams.

“Some teams had six to eight people,” Chadwick said. “We’re just a team of two.”