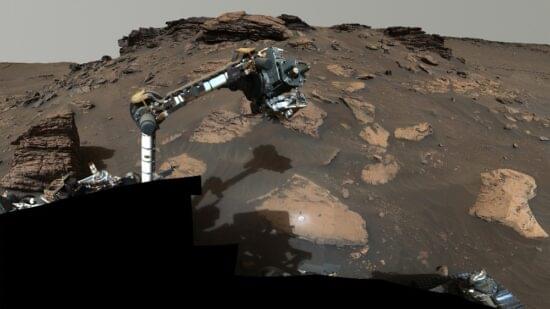

The word “intriguing” is being used to describe Perseverance results coming from sedimentary rocks on Mars that are of the same type known for preserving fossils and evidence of life here on Earth.

When NASA landed the Perseverance rover on Mars complete with an instrument package capable of identifying organic molecules, the Agency chose the Jezero Crater, the site of an ancient water-formed delta dating back 3.5 billion Earth years. The goal was to look for signs of ancient Martians, not the Martians of H.G. Wells’ “War of the Worlds,” but rather microorganisms like the ones that killed off the Martians after they arrived.

Onboard Perseverance is an instrumentation package that goes by the acronym SHERLOC which stands for Scanning Habitable Environments with Raman and Luminescence for Organics and Chemicals. Using SHERLOC, Perseverance has been sampling sedimentary rocks laid down by the water that flowed on the Martian surface earlier in its history.

What does the presence of organic molecules in samples tell us about the existence of past or present life on Mars? Although organic molecules may form from chemical processes where life is not present, it usually is a good sign of its existence. And Perseverance isn’t the first Martian lander or rover to discover organic molecules. The Viking landers, and now defunct rovers, Spirit, and Opportunity, have all indicated that Mars could or did harbour life in the past. Curiosity, the other active Martian rover in the Gale Crater has made similar discoveries. The difference between the two rovers, however, is one of both quantity and quality when looking at the Perseverance samples. Perseverance has found far more organic molecules than its sister rover and is caching the samples for a future mission to find, gather and return to Earth for study.