What is really going on with Virgin Galactic, Get the inside scoop from the initial developer of the engine technology who worked for Burt Rutan on SpaceShipOne and also worked SpaceShipTwo-Tim Pickens, See why he, and I are concerned about Virgin Galactic.

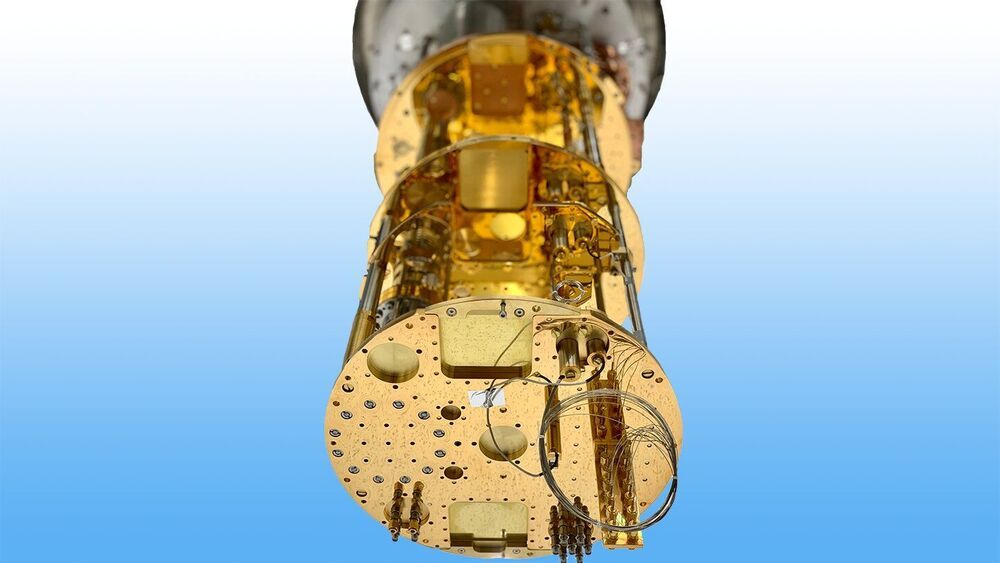

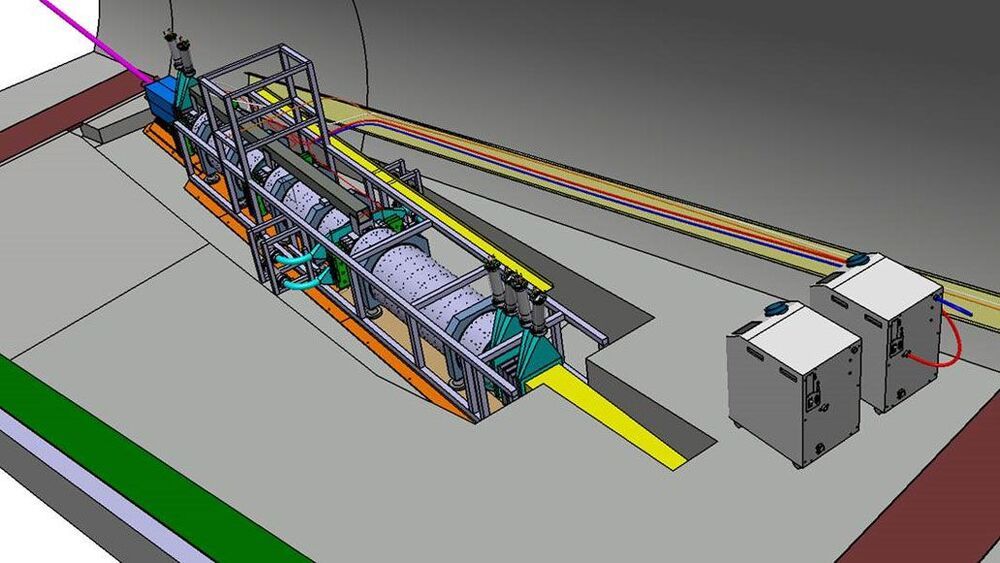

Tim Pickens is an entrepreneur, inventor, innovator, engineer and educator. He specializes in commercial space, technical product development and solutions, and business consulting and strategy for space and technical companies. He is known for applying a lean philosophy to develop creative solutions and innovative partnerships to provide responsive, low-cost products and services for government and private industry. Pickens’ 25+ years of experience in the aerospace industry, specializing in the design, fabrication and testing of propulsion hardware systems, has earned him a reputation as one of the industry’s leaders in these areas. Early in his career, Pickens served as propulsion lead for Scaled Composites on SpaceShipOne, winner of the $10 million Ansari X Prize. He also worked for small hardware-rich aerospace companies in Huntsville, and later supported the Virgin Galactic’s SpaceShipTwo venture.

You can support Galactic Gregs by supporting the sister channel Green Gregs by clicking the links below:

For your space habitat garden buy worms at greengregs.com!

See the Special Deals at My Patriot Supply (great space mission food): www.PrepWithGreg.com.

For gardening in your space habitat (or on Earth) Galactic Gregs has teamed up with True Leaf Market to bring you a great selection of seed for your planting. Check it out: http://www.pntrac.com/t/TUJGRklGSkJGTU1IS0hCRkpIRk1K