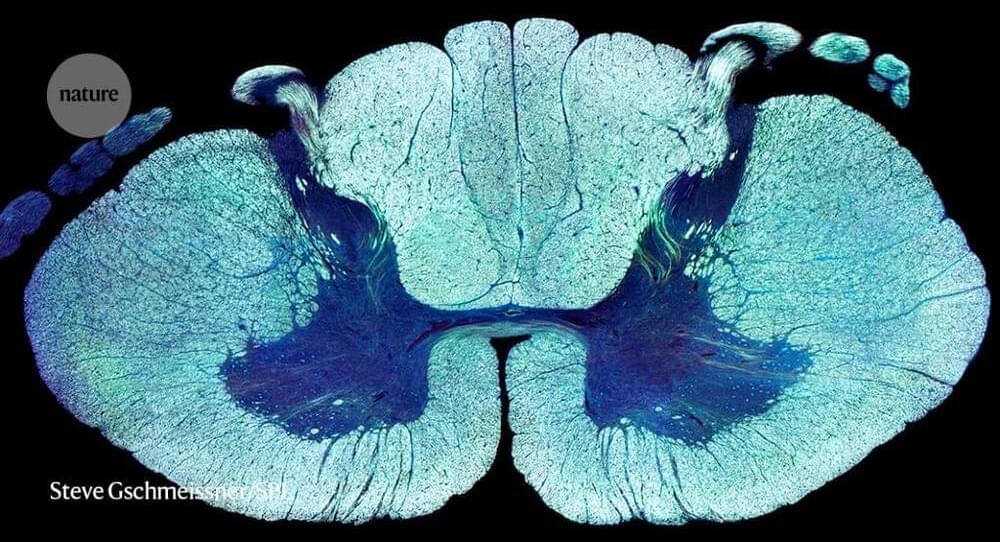

Detailed gene-activity map could pave way for more precise treatments for many more people with spinal-cord injuries.

Narrated by Laurence Fishburne (The Matrix, Apocalypse Now, Batman v Superman: Dawn of Justice), Year Million brings to life the ideas and innovations that will power our evolution throughout the universe.

Each episode will follow the story of a family as they navigate through the future, one invention at a time.

National Geographic is available in the UK on Sky, Virgin Media, TalkTalk and BT. Visit natgeotv.com for exclusive videos and TV listings.

Researchers believe that synthetic muscle fibers could be used in a wide variety of sustainable and environmentally friendly industrial applications, including textiles, biomedicine, and tissue engineering. In a world where it takes up to 1,800 gallons of water to produce a single pair of jeans, the development of such environmentally safe processes that provide high-strength materials for industrial applications is a great step forward.

How strong can a muscle ever get? Can it have more endurance than metal? Can it be sturdier than Kevlar? While you might be inclined to answer the above in the negative, please pause, for scientists have succeeded in developing synthetic muscle that’s stronger than Kevlar. How about that for a flex?

The science and other stuff to know

The breakthrough was achieved by researchers at the McKelvey School of Engineering at Washington University, and the findings were reported in a study published in Nature Communications in August.

Secure communications provider Wickr has announced that it will shutter its free encrypted messaging app, Wickr Me, next year.

Text messaging has been around since the dawn of cellular technology, and sparked its own unique language. But it’s time to put sending regular SMS messages out to pasture.

If you have an iPhone, you’re already on your way. iPhones (as well as iPads and Macs) use iMessage to send messages between Apple devices. It’s a data-based messaging system reliant on 3G, 4G, and Wi-Fi, rather than SMS messaging, which uses an old, outdated but universal 2G cellular network. iMessage has grown in popularity, but has left Android devices and other computers out in the dark.

That’s where other messaging services have filled a gap in the market.

It will be the sight of astronauts on the moon, their gaze drawn to the strange movements of planet Earth and its sun, something that is sure to be an amusing sight for future NASA astronauts at the moon’s south pole.

This visualization shows the unusual movements of the Earth and the Sun as seen from the South Pole of the Moon. The animation compresses three months (a little over three lunar days) into two minutes. The virtual camera is on the rim of the Shackleton crater, partially visible in the lower right, and is pointed at Earth. The mountain on the horizon, some 85 miles away, is unofficially known as Mons Malapert.

Here, the Sun glides across the horizon, never more than 1.5 degrees above or below it, while the Earth bobs up and down, never straying from 0° longitude. The Earth appears to be upside down and spinning backward. The Sun’s perpetually low angle casts extremely long swirling shadows over the rugged lunar terrain.

In the second month of the visualization, the Earth passes in front of the Sun, creating an eclipse. For observers on Earth, this is a lunar eclipse, in which the Moon passes through the shadow cast by the Earth. However, seen from the Moon, it is an eclipse of the Sun.

Video Credit: NASA Goddard Space Flight Center Visualizations by: Ernie Wright (USRA) Narrated by: Ernie Wright (USRA) Produced and Edited by: David Ladd (AIMM) Principal Scientist: Noah Petro (NASA/GSFC) Technical Support: Laurence Schuler (ADNET), net. /Jones (ADNET)

Music provided by Universal Production Music: “Enwhileing Faith” — Frederik Wiedmann.

https://svs.gsfc.nasa.gov/4944. https://nasa.gov/multimedia/guidelines.

Godard of NASA.

While some might view the emergence of humanoids with apprehension, a future filled with robots is likely to be a positive development for most. But as with anything, policy and society must be ready if, and when, they arrive.

There is growing corporate interest in humanoid robots to replace human labor. Tesla’s recently unveiled Bumble C robot may mark a turning point in an industry that has thus far focused on specialized machines produced in limited quantities. Should Tesla succeed, what does a mass-produced humanoid robot mean for the future of humanity?

Visit our sponsor, Brilliant: https://brilliant.org/IsaacArthur/

Revolutionary improvements to automation and production may one day create machines able to produce almost anything, quickly and cheaply, and far faster and more varied than modern 3D Printers. Such devices are sometimes known as Santa Claus Machines, Cornucopia Devices, or Clanking Del-Replicators, and today we will examine how likely such technology is, how far off in the future they might be, and what impact they would have on society.

Visit our Website: http://www.isaacarthur.net.

Support us on Patreon: https://www.patreon.com/IsaacArthur.

or Paypal at: https://www.paypal.me/IsaacArthur.

SFIA Merchandise available: https://www.signil.com/sfia/

Social Media:

Facebook Group: https://www.facebook.com/groups/1583992725237264/

Reddit: https://www.reddit.com/r/IsaacArthur/

Twitter: https://twitter.com/Isaac_A_Arthur on Twitter and RT our future content.

SFIA Discord Server: https://discord.gg/53GAShE

Listen or Download the audio of this episode from Soundcloud: Episode’s Audio-only version: https://soundcloud.com/isaac-arthur-148927746/santa-claus-machine.

Episode’s Narration-only version: https://soundcloud.com/isaac-arthur-148927746/santa-claus-machine-narration-only.

Credits:

The Santa Claus Machine.

Episode 165, Season 4 E51

Writers.