The person staring back from the computer screen may not actually exist, thanks to artificial intelligence (AI) capable of generating convincing but ultimately fake images of human faces. Now this same technology may power the next wave of innovations in materials design, according to Penn State scientists.

“We hear a lot about deepfakes in the news today – AI that can generate realistic images of human faces that don’t correspond to real people,” said Wesley Reinhart, assistant professor of materials science and engineering and Institute for Computational and Data Sciences faculty co-hire, at Penn State. “That’s exactly the same technology we used in our research. We’re basically just swapping out this example of images of human faces for elemental compositions of high-performance alloys.”

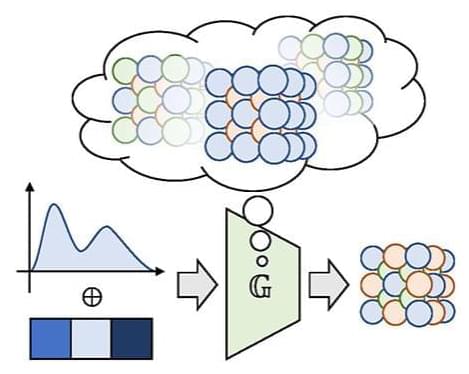

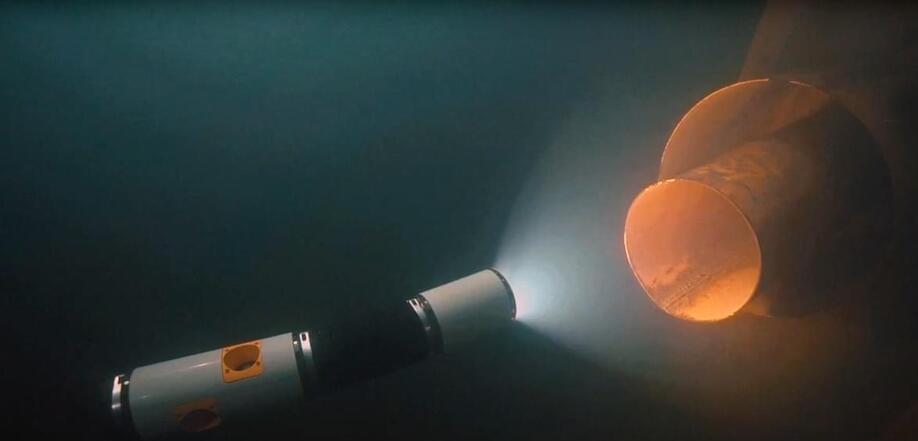

The scientists trained a generative adversarial network (GAN) to create novel refractory high-entropy alloys, materials that can withstand ultra-high temperatures while maintaining their strength and that are used in technology from turbine blades to rockets.