Food tech startup Farther Farms has developed a process that keeps foods that would normally need to be refrigerated or frozen fresh at room temperature — and their first product is a bag of shelf-stable French fries.

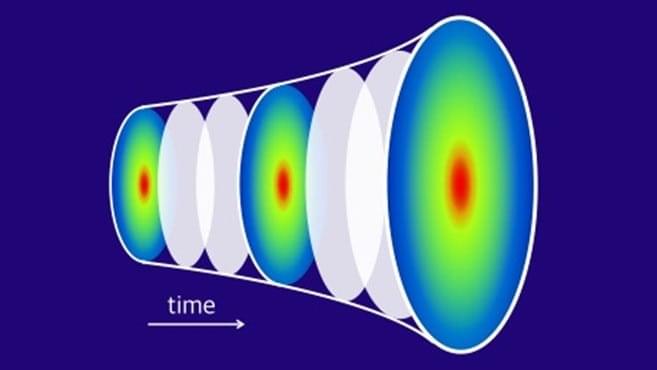

The cold chain: Microorganisms are a major cause of food spoilage, and they thrive at room temperature. By keeping some foods cold, we can slow the growth of these microbes, extending the life of the food.

To do that, the foods must be prepared, shipped, and stored along a temperature-controlled supply chain (a “cold chain”). If the cold chain is broken at any point along the way, the food may quickly become unsafe to eat.