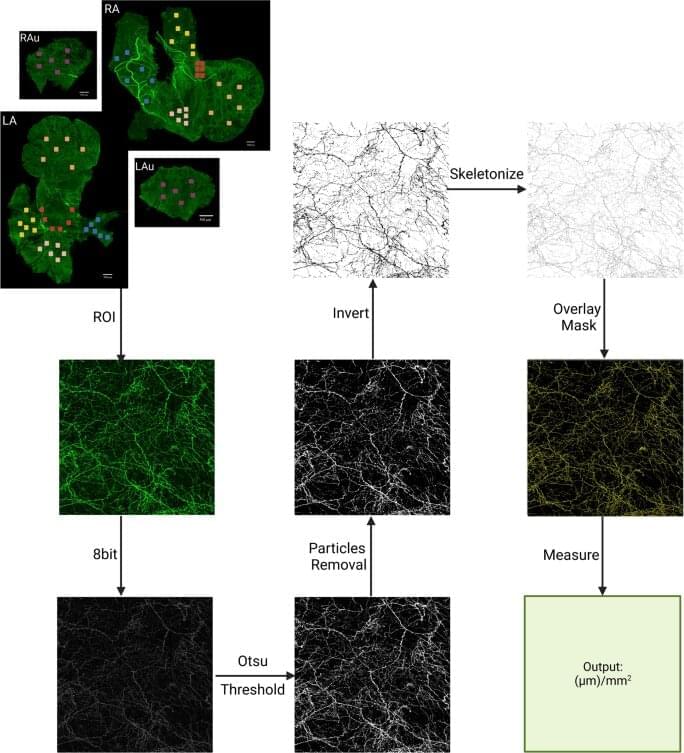

A team of UCF College of Medicine researchers has created a digital topographical map of the cardiac sympathetic neural network, the region that controls the body’s heart rate and its “fight-or-flight” response. They hope this map will eventually serve as a guide to treat cardiovascular conditions using bioelectronic devices.

The study, led by Dr. Zixi Jack Cheng, a neuro-cardiovascular scientist, was published in the Scientific Reports journal and was the project of an interdisciplinary team of researchers from UCF along with several other institutions as well as industry partners MBF Bioscience and SPARC Data and Resource Center.

“This mapping goes beyond what you can find in a textbook,” Dr. Cheng said. “This is a digitized brain–heart atlas that will be interactive. We hope it will serve as a guide not only for scientists and physicians, but also for students as they learn the neuroanatomy of the heart.”

עברית (Hebrew)

עברית (Hebrew)