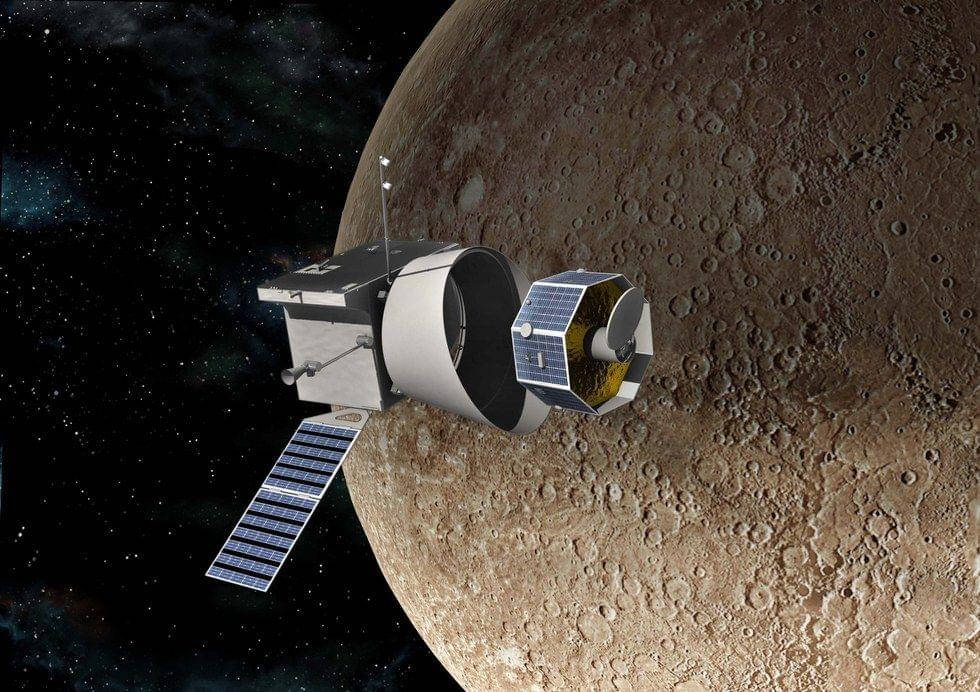

BepiColombo will be only the second mission in history to orbit Mercury, the scorched rocky planet close to the sun.

How the Big Bang gave us time, explained by theoretical physicist Sean Carroll.

Up next, The Universe in 90 minutes: Time, free will, God, & more ► https://youtu.be/tM4sLmt1Ui8

In this Big Think interview, theoretical physicist Sean Carroll discusses the concept of time and the mysteries surrounding its properties. He notes that while we use the word “time” frequently in everyday language, the real puzzles arise when we consider the properties of time, such as the past, present, and future, and the fact that we can affect the future but not the past.

Carroll also discusses the concept of entropy, which is a measure of how disorganized or random a system is, and the second law of thermodynamics, which states that there is a natural tendency for things in the universe to go from a state of low entropy to high entropy. He explains that the arrow of time, or the perceived difference between the past and the future, arises due to the influence of the Big Bang and the fact that the universe began in a state of low entropy.

Carroll also touches on the possibility of time travel and the concept of the multiverse.

Read the video transcript ► https://bigthink.com/series/explain-it-like-im-smart/the-Big-Bang-gave-us-time.

Tesla Cybertruck sightings are continuing, and a video of the all-electric pickup released today gives a much better look at the vehicle’s air suspension.

Last night, a video of the Cybertruck rolling around Gigafactory Texas was shared, showing off its air suspension at what people said was its maximum ride height. However, it was very unclear and grainy, so it didn’t necessarily give a great look at what the Cybertruck will look like when utilizing its air suspension.

Now, a new video has been shared, where the Cybertruck appears to be, once again, at its maximum ride height, thanks to its air suspension, but the clearer resolution gives us a much more revealing look at the beast in its rarest form.

Check out all the on-demand sessions from the Intelligent Security Summit here.

Permissions management is the essence of data security. Yet few security teams can manage identities in the cloud at scale, with Gartner estimating that by 2023, 75% of cloud security failures will occur due to insufficient management of identities, access and privileges.

However, more and more providers are looking to address permissions management with automation. Entitle, which today announced it has raised $15 million as part of a seed funding round led by Glilot Capital Partners, offers a platform for automating access management and provisioning.

Our new series The Future with Hannah Fry explores the science, tech and people on the cusp of the most transformative breakthroughs of our age – from AI to clean energy. Watch the first episode on Bloomberg Originals on Feb. 22.

–

Do you want to know what your future holds? A life beyond 150 years old? A world where computers can read our emotions? A planet transformed by unlimited clean energy? Mathematician Hannah Fry will explore these questions and more in the new series The Future With Hannah Fry, debuting on Bloomberg Originals on Feb. 22.

Watch The Future With Hannah Fry on Wednesdays at 8:30 p.m. ET on Bloomberg.com, the Bloomberg app on your connected TV, Apple TV, Roku, Samsung TV.

——-

Like this video? Subscribe: https://www.youtube.com/Bloomberg?sub_confirmation=1

Become a Quicktake Member for exclusive perks: https://www.youtube.com/bloomberg/join.

Bloomberg Originals offers bold takes for curious minds on today’s biggest topics. Hosted by experts covering stories you haven’t seen and viewpoints you haven’t heard, you’ll discover cinematic, data-led shows that investigate the intersection of business and culture. Exploring every angle of climate change, technology, finance, sports and beyond, Bloomberg Originals is business as you’ve never seen it.

Subscribe for business news, but not as you’ve known it: exclusive interviews, fascinating profiles, data-driven analysis, and the latest in tech innovation from around the world.

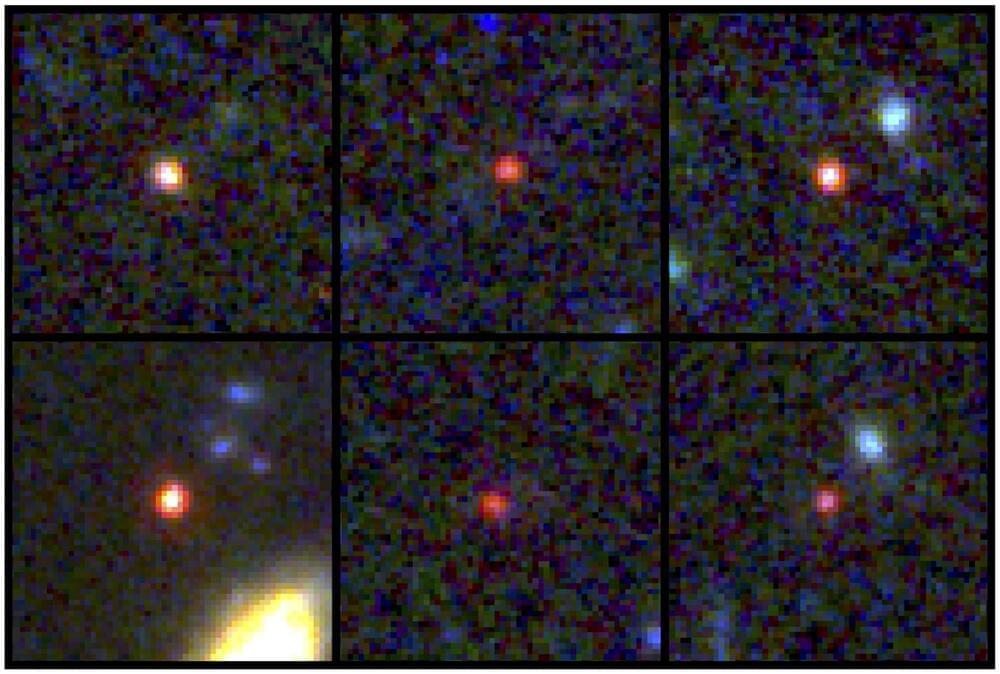

Six massive galaxies discovered in the early universe are upending what scientists previously understood about the origins of galaxies in the universe.

“These objects are way more massive than anyone expected,” said Joel Leja, assistant professor of astronomy and astrophysics at Penn State, who modeled light from these galaxies. “We expected only to find tiny, young, baby galaxies at this point in time, but we’ve discovered galaxies as mature as our own in what was previously understood to be the dawn of the universe.”

Using the first dataset released from NASA’s James Webb Space Telescope, the international team of scientists discovered objects as mature as the Milky Way when the universe was only 3% of its current age, about 500–700 million years after the Big Bang. The telescope is equipped with infrared-sensing instruments capable of detecting light that was emitted by the most ancient stars and galaxies. Essentially, the telescope allows scientists to see back in time roughly 13.5 billion years, near the beginning of the universe as we know it, Leja explained.

😗

The measurements from ancient and dormant galaxies show black holes growing more than expected, aligning with a phenomenon predicted in Einstein’s theory of gravity. The result potentially means nothing new has to be added to our picture of the Universe to account for dark energy: black holes combined with Einstein’s gravity are the source.

Study co-author Dr Chris Pearson, from STFC RAL Space, said: “If the theory holds, then this is going to revolutionize the whole of cosmology, because at last we’ve got a solution for the origin of dark energy that’s been perplexing cosmologists and theoretical physicists for more than 20 years.”

Year 2015 face_with_colon_three

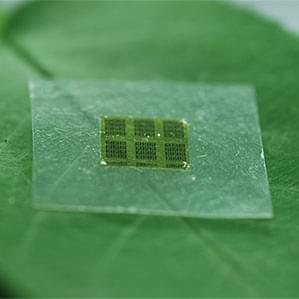

Biodegradable, wood-based computer chips can perform just as well as chips commonly used for wireless communication, according to new research.

The inventors argue that the new chips could help address the global problem of rapidly accumulating electronic waste, some of which contains potentially toxic materials. The results also show that a transparent, wood-derived material called nanocellulose paper is an attractive alternative to plastic as a surface for flexible electronics.