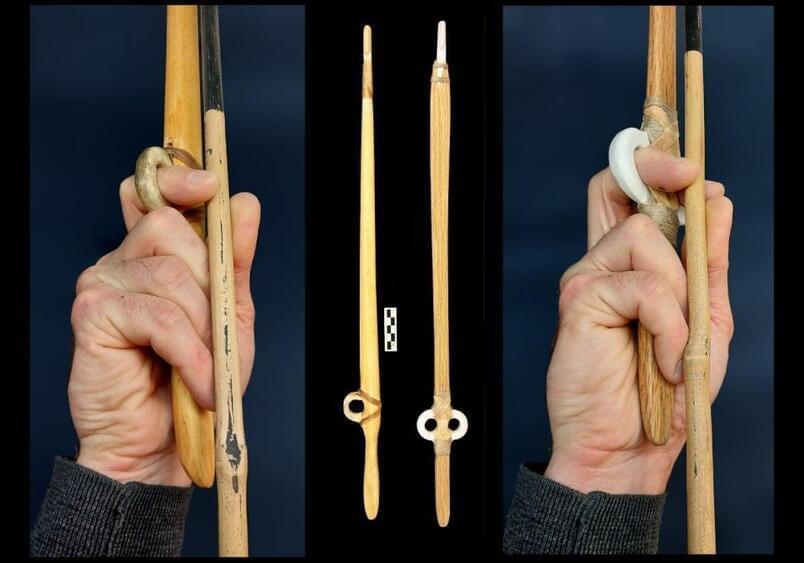

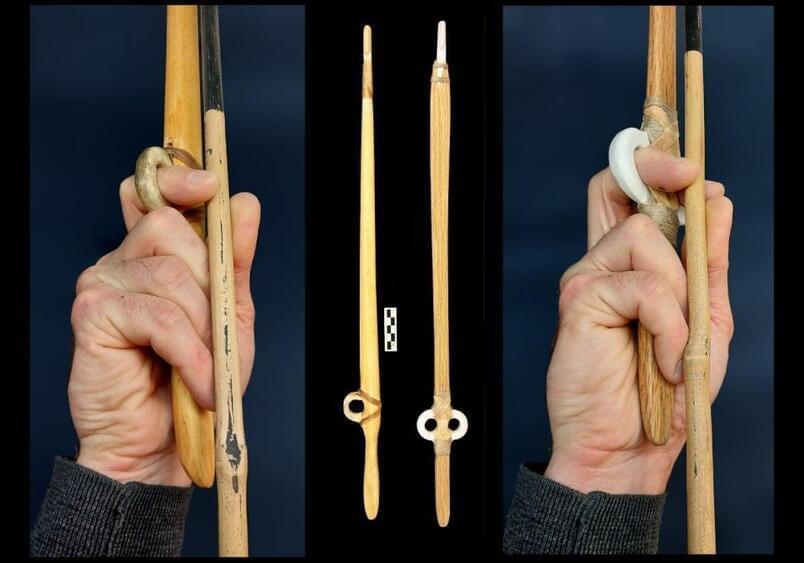

Hurling spear-thrower projectiles at archery targets revealed that these loops may have been finger grips.

The current understanding of the biology of aging is largely based on research aimed at identifying factors that influence lifespan. However, lifespan as a sole proxy measure of aging has limitations because it can be influenced by specific pathologies (not generalized physiological deterioration in old age). Hence, there is a great need to discuss and design experimental approaches that are well-suited for studies targeting the biology of aging, rather than the biology of specific pathologies that restrict the lifespan of a given species. For this purpose, we here review various perspectives on aging, discuss agreement and disagreement among researchers on the definition of aging, and show that while slightly different aspects are emphasized, a widely accepted feature, shared across many definitions, is that aging is accompanied by phenotypic changes that occur in a population over the course of an average lifespan. We then discuss experimental approaches that are in line with these considerations, including multidimensional analytical frameworks as well as designs that facilitate the proper assessment of intervention effects on aging rate. The proposed framework can guide discovery approaches to aging mechanisms in all key model organisms (e.g., mouse, fish models, D. melanogaster, C. elegans) as well as in humans.

Keywords: Aging; experimental design; lifespan; models; phenotypes.

Copyright © 2023 Elsevier B.V. All rights reserved.

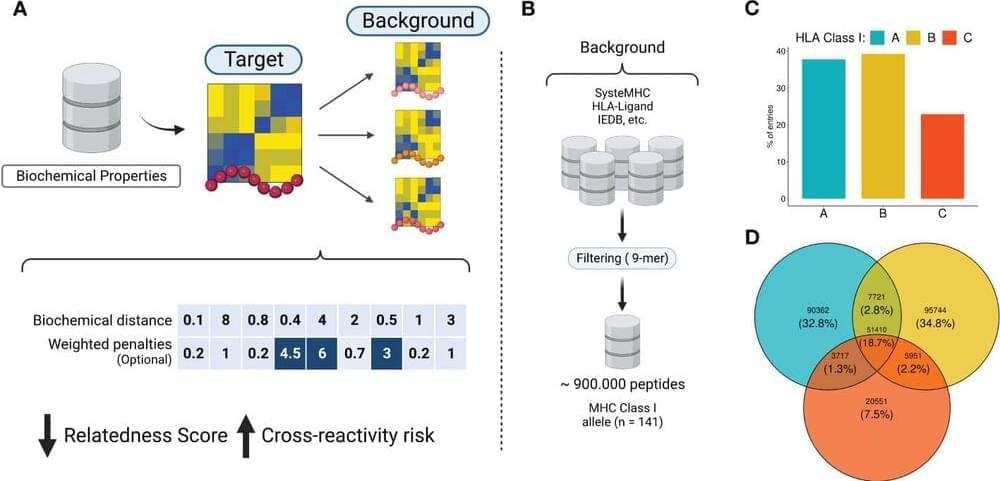

Researchers at the University of Houston are working to make T-cell immunotherapy safer, developing a tool called CrossDome, which uses a combination of genetic and biochemical information to predict if T-cell immunotherapies might mistakenly attack healthy cells.

T-cell based immunotherapies hold tremendous potential in the fight against cancer and infectious diseases, thanks to their capacity to specifically target diseased cells, including cancer metastasis. Nevertheless, this potential has been tempered with safety concerns regarding the possible recognition of unknown off targets displayed by healthy cells.

In one case, scientists created special T-cells that were supposed to target a protein found in a type of skin cancer called melanoma. However, these T-cells also ended up attacking a different protein found in the heart cells of some patients. This caused severe damage to the heart.

NEW YORK, June 13 (Reuters) — Meta Platforms (META.O) said on Tuesday that it would provide researchers with access to components of a new “human-like” artificial intelligence model that it said can analyze and complete unfinished images more accurately than existing models.

The model, I-JEPA, uses background knowledge about the world to fill in missing pieces of images, rather than looking only at nearby pixels like other generative AI models, the company said.

That approach incorporates the kind of human-like reasoning advocated by Meta’s top AI scientist Yann LeCun and helps the technology to avoid errors that are common to AI-generated images, like hands with extra fingers, it said.

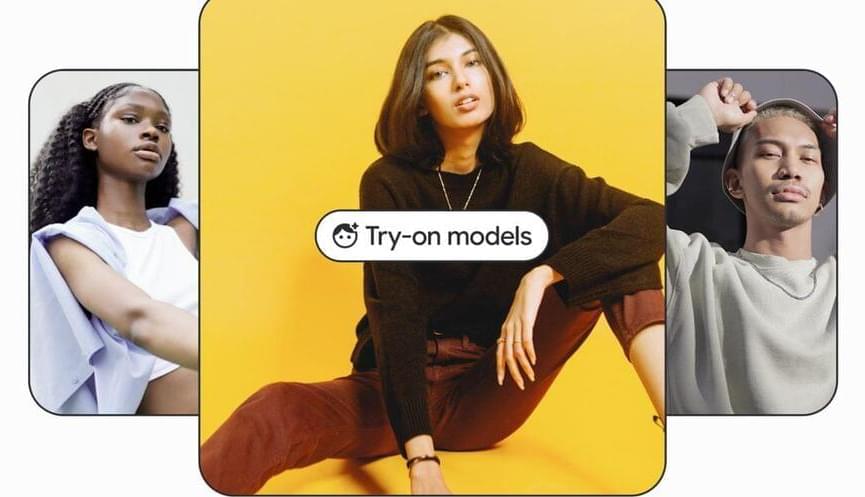

Starting today, users in the US can see how women’s tops from H&M, Anthropologie, Everlane, and Loft will look on a wide range of real human models. New filters aim to make finding clothes easier.

Google is introducing two new features for its online shopping experience that are designed to help users search for clothes in more detail and better visualize how clothing will look on different body types.

Starting today, Google Shopping users in the US can access a virtual try-on experience that realistically displays how an item of clothing will look on a selection of real human models. These models are available with various skin tones, ethnicities, hair types, and body shapes, ranging in size… More.

Users can now view how clothing looks on a range of diverse models.

OpenAI CEO Sam Altman over the weekend called for enhanced collaboration between the U.S. and China on artificial intelligence development. Without mentioning the fact that his company’s products like ChatGPT are not available in China, he argued that China should be a major player in ensuring the safety of global AI development and rollout.

“With the emergence of the increasingly powerful AI systems, the stakes for global cooperation have never been higher,” he said in the keynote address for a conference hosted by the Beijing Academy of Artificial Intelligence, sounding more like someone leading an advocacy group on responsible tech than what he is: the CEO of a company responsible for shepherding that emergence.

Altman’s call for U.S.-China collaboration on “mitigating risk” is only the latest (and, given the state of U.S.-China technological competition, possibly the most hazardous) incident in his quest to convince the world to regulate his industry. Unlike other tech leaders, he has been eager to meet with policymakers around the world, not just in the United States but also in South America, Africa, Europe and Asia, in an effort to encourage and influence the development of AI regulations. Presumably, he is advocating for rules that would benefit OpenAI’s business interests.

A team of researchers in the United States and United Kingdom say they have created the world’s first synthetic human embryo-like structures from stem cells, bypassing the need for eggs and sperm.

These embryo-like structures are at the very earliest stages of human development: They don’t have a beating heart or a brain, for example. But scientists say they could one day help advance the understanding of genetic diseases or the causes of miscarriages.

The research raises critical legal and ethical questions, and many countries, including the US, don’t have laws governing the creation or treatment of synthetic embryos.

“Even though recent months have seen AI labs locked in an out-of-control race to develop and deploy ever more powerful digital minds that no one—not even their creators—can understand, predict, or reliably control,” stated the letter.

The idea is that AI development should be “planned for and managed with commensurate care and resources.” However, the authors of the letter say that this level of planning is not happening. This leads to AI systems that are out of control.

Transparently communicating the limitations of the model and providing clear disclaimers when interacting with users can foster trust and accountability.