An interdisciplinary team of clinicians and scientists has published a consensus paper recommending appropriate quantitative imaging techniques for coronary artery stenosis and atherosclerosis related treatment and procedural planning. The paper has been published in Nature Reviews Cardiology.

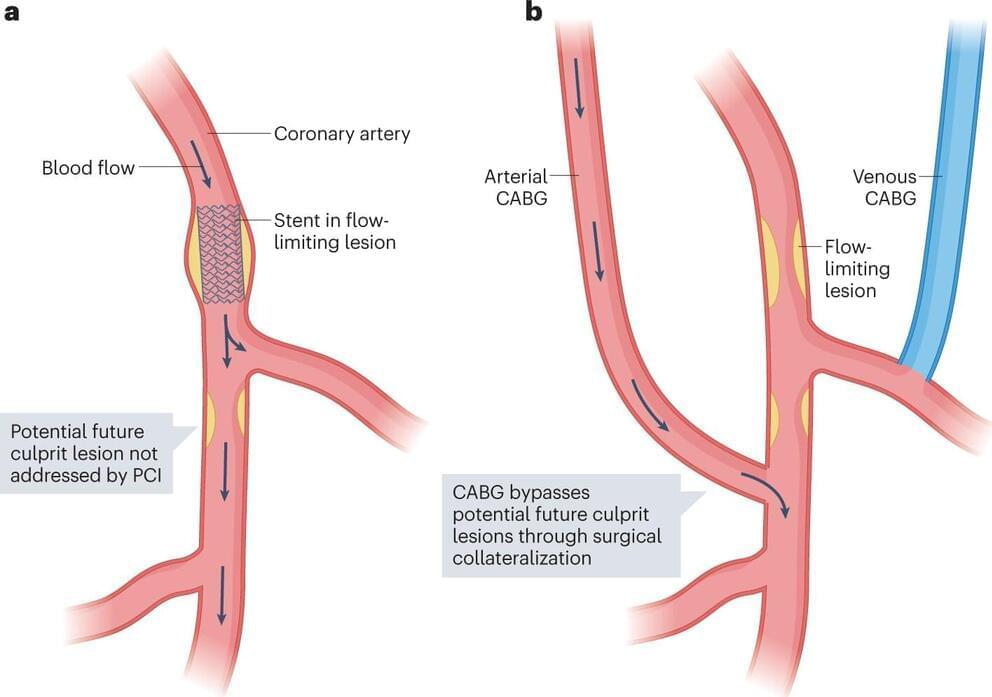

Quantitative imaging has become increasingly important for the diagnosis of coronary artery disease (CAD) over the past five years. This is because new quantitative techniques can detect narrowed coronary arteries (coronary artery stenoses) and atherosclerosis, which play a major role in CHD patients.

It is important to correctly diagnose and accurately assess the severity of coronary artery stenosis or the extent of atherosclerotic burden for the selection of appropriate measures of therapy and the related further course of the disease. However, the complexity and variety of different quantitative imaging modalities, such as computed tomography (CT), magnetic resonance imaging (MRI), invasive coronary angiography (ICA), intravascular ultrasound (IVUS), and optical coherence tomography (OCT), necessitated a comprehensive clinical consensus.