Adversity experienced by mothers during their childhood or pregnancy is reflected in their children’s gut microbiomes, a recent study found.

Our gut microorganisms, collectively known as the gut microbiota, affect far more than digestion. Bacteria in our intestinal tracts influence brain activity — and even the likelihood of developing mental disorders. Decades of research have shown that a bacterially imbalanced gut can disrupt many systems in the human body, contributing to obesity, malnutrition and even cancer. In a study published May 10 in Nature, Stanford Medicine researchers and collaborators used an ingestible device to capture the diversity of microorganisms, viruses, proteins and bile in the small intestine.

The proof-of-concept results provide early evidence that there are more comprehensive ways to measure microbiota in the digestive system than current sampling methods — which mostly focus on stool — and shed new light on how resident gut microbes might contribute to human physiology and disease.

“This paper demonstrates a big leap forward in microbial detection and captures the living gut microbiota in a nutshell,” said co-senior author KC Huang, PhD, a professor of bioengineering and of microbiology and immunology, co-senior author with David Relman, MD, a professor of medicine and of microbiology and immunology. “Samples from current tools don’t fully represent what’s going on inside of us. But it’s all we’ve had — until now.”

Data captured and fed into an AI model should be used to shape and inform marketing programs for the betterment of the customer’s experience. Such a practice enables marketers to utilize valuable information but doesn’t put data privacy at risk. Humans maintain control and can add their own handprint to AI-generated content to develop something much more meaningful that resonates with targeted audiences. Within that construct, marketers must bring the heart and the emotional intelligence to generative AI if they want to maximize its potential while maintaining ethical boundaries.

Human-connected generative AI is poised to be the ultimate tool if used responsibly. It can recognize patterns and insights and develop recommendations for actions, effectively making workers smarter and better at their jobs.

Most businesses see generative AI’s capabilities as opportunities to do more with less. Now it’s time to take the next step forward, connecting data insights with personalized content to ethically move through the pipeline at a new level of speed and efficiency—and in a manner that’s rewarding and enriching for customers.

Some best practices for longevity can be a real bummer. Everyone knows that regular exercise is good for them, but not everyone enjoys it. Eating a few cups of veggies with every meal may not be as fun as a side of fries.

But every so often, the things that are good for us feel good too. Case in point: the humble massage.

A massage for most people is a spa-day splurge, but it’s also an ancient medicinal practice. A thorough rub-down is a great way to celebrate the end of a stressful semester, but there’s more to it than much-deserved relaxation. At its best, a good massage improves bodily motion and function. While science doesn’t say that each massage adds years to your life (not yet, anyway), the benefits of regular massages (for those lucky enough to get them) can add up over time.

We’re not at the scope of usage Cameron is anxious about yet, but we don’t have to imagine what AI’s role in the military could look like hypothetically—it’s already starting to happen. The U.S. Department of Defense is already investigating moves to create an archive of military data to use as part of what it sees as an escalating digital arms race with other nations, and the eventual weaponization of such technology. Not that Cameron himself hasn’t already thought about that extensively in his own filmmaking career already, of course.

“I warned you guys in 1984 and you didn’t listen,” the director not-so-jokingly added. But you know, hopefully we get protections for actors, writers, directors, and other creatives against generative AI replacements before we have to worry too much about someone making Skynet. Hopefully.

I gotta admit although effective and innovative, it’s also kinda creepy.

Last year, Monash University scientists created the “DishBrain” – a semi-biological computer chip with some 800,000 human and mouse brain cells lab-grown into its electrodes. Demonstrating something like sentience, it learned to play Pong within five minutes.

The micro-electrode array at the heart of the DishBrain was capable both of reading activity in the brain cells, and stimulating them with electrical signals, so the research team set up a version of Pong where the brain cells were fed a moving electrical stimulus to represent which side of the “screen” the ball was on, and how far away from the paddle it was. They allowed the brain cells to act on the paddle, moving it left and right.

Then they set up a very basic-reward system, using the fact that small clusters of brain cells tend to try to minimize unpredictability in their environment. So if the paddle hit the ball, the cells would receive a nice, predictable stimulus. But if it missed, the cells would get four seconds of totally unpredictable stimulation.

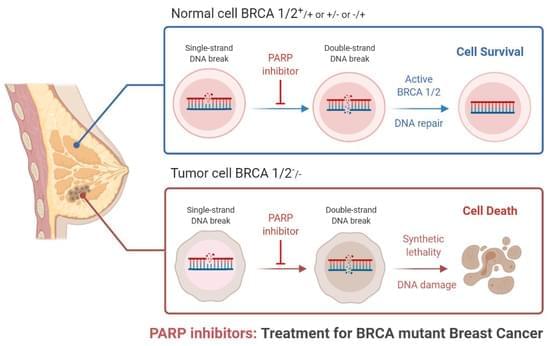

Triple-negative breast cancer is a combative cancer type with a highly inflated histological grade that leads to poor theragnostic value. Gene, protein, and receptor-specific targets have shown effective clinical outcomes in patients with TNBC. Cells are frequently exposed to DNA-damaging agents. DNA damage is repaired by multiple pathways; accumulations of mutations occur due to damage to one or more pathways and lead to alterations in normal cellular mechanisms, which lead to development of tumors. Advances in target-specific cancer therapies have shown significant momentum; most treatment options cause off-target toxicity and side effects on healthy tissues.

Novel Harm Reduction Strategies For The Opioid Epidemic — Harmguard FX — Jermonica Boardley & Joseph Scrocco — Sivad Group LLC / Diagnostic Solutions Group

Jermonica Boardley is President and CEO of SIVAD Diagnostic Medical Group LLC (https://sivadppe.com/), a minority-owned company dedicated to addressing the unique needs of underserved and unserved communities in the United States and globally, which most recently announced the launch of HarmGuard FX (https://www.harmstopper.com/), a single, low-cost strip that provides an affordable, reliable way for people to test substances for fentanyl and xylazine (popularly known as tranq), two dangerous adulterants that are exacerbating the already critical opioid epidemic.

Ms. Boardley is a graduate of Delaware State University, brings over 20 years of diverse corporate leadership experience to her role as President and CEO and her expertise spans Accounting, Finance, Human Resources, Communications, and Diversity, Equity & Inclusion (DE&I).

Joseph Scrocco, is President & CEO, Diagnostic Solutions Group (https://www.diagnosticsolutionsgroup.com/), the developer of HarmGuardFX, and their company has developed custom diagnostic solutions for over 25 years ranging from complex mass screening for blood banks to individual point-of-care testing with a focus on large-scale, global diagnostic needs, including antibody, molecular, and antigen tests in traditional and non-traditional settings. Their clients include Johnson & Johnson; Pfizer; Novo Nordisk; Abbott Labs; Ortho Clinical Diagnostics; the Red Cross; the governments of Nigeria, Ivory Coast, Bangladesh, Liberia, Jamaica, India, Mali; numerous Broadway companies; plus, hundreds of hospitals, urgent care centers, and long-term care facilities.

Mr. Scrocco has a MS in Neurophysiology from University of Medicine and Dentistry of New Jersey, and an MA in Information Systems from New York University.

Alex’s lemonade stand foundation — fighting childhood cancer, one cup at a time! liz scott, co-executive director, alex’s lemonade stand foundation.

Liz Scott is Co-Executive Director, of Alex’s Lemonade Stand Foundation for Childhood Cancer (ALSF — https://www.alexslemonade.org/), an organization which emerged from the front yard lemonade stand of her daughter, Alexandra “Alex” Scott (1996−2004).

In 2000, at the age of four, Alex announced that she wanted to hold a lemonade stand to raise money to help find a cure for other children with cancer, herself already bravely fighting neuroblastoma, which she was diagnosed with at age one.

Over her lifetime, Alex would raise over $1 million before she passed away in 2004 at the age of 8. Since then, Liz and her husband Jay have worked alongside thousands of supporters across the country to carry on Alex’s legacy of hope.

To date, ALSF has raised more than $250 Million toward fulfilling Alex’s dream of finding a cure, funding over 1,000 pediatric cancer research projects nationally.