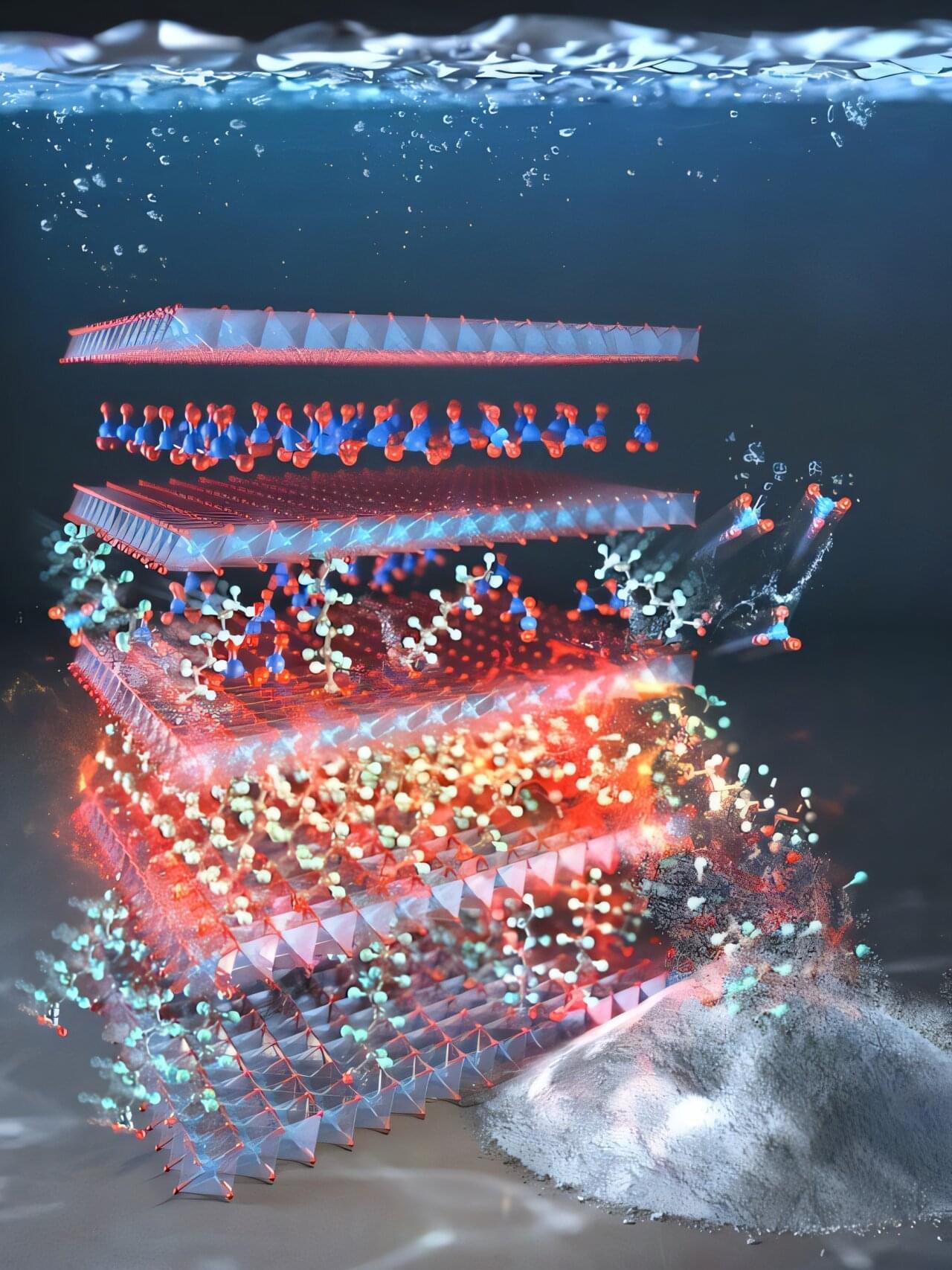

A new one‑step, water‑, acid‑, and alkali‑free method for extracting high‑purity lithium from spodumene ore has the potential to transform critical metal processing and enhance renewable energy supply chains. The study is published in Science Advances.

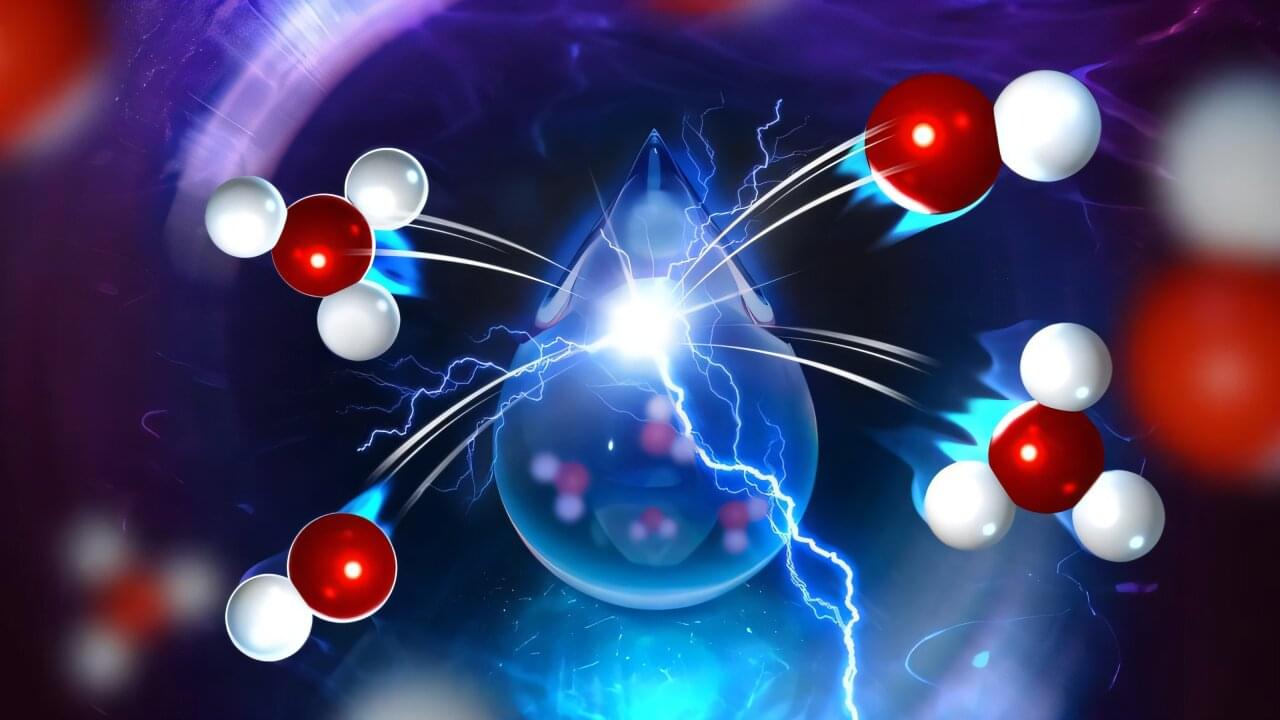

As the demand for lithium continues to rise, particularly for use in electric cars, smartphones and power storage, current extraction methods are struggling to keep pace. Extracting lithium from salty water is a lengthy process, and traditional methods that use heat and chemicals to extract lithium from rock produce significant amounts of harmful waste.

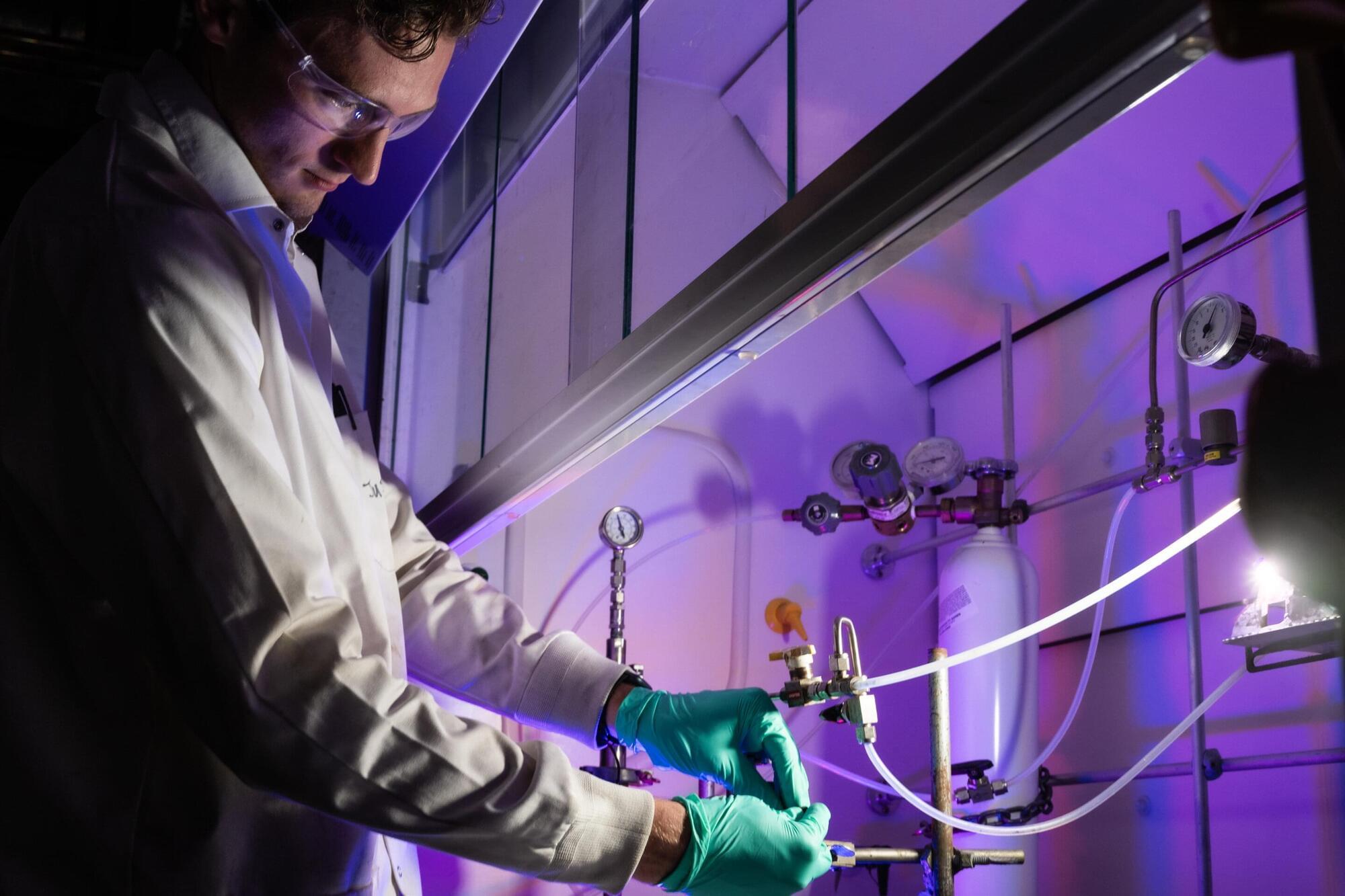

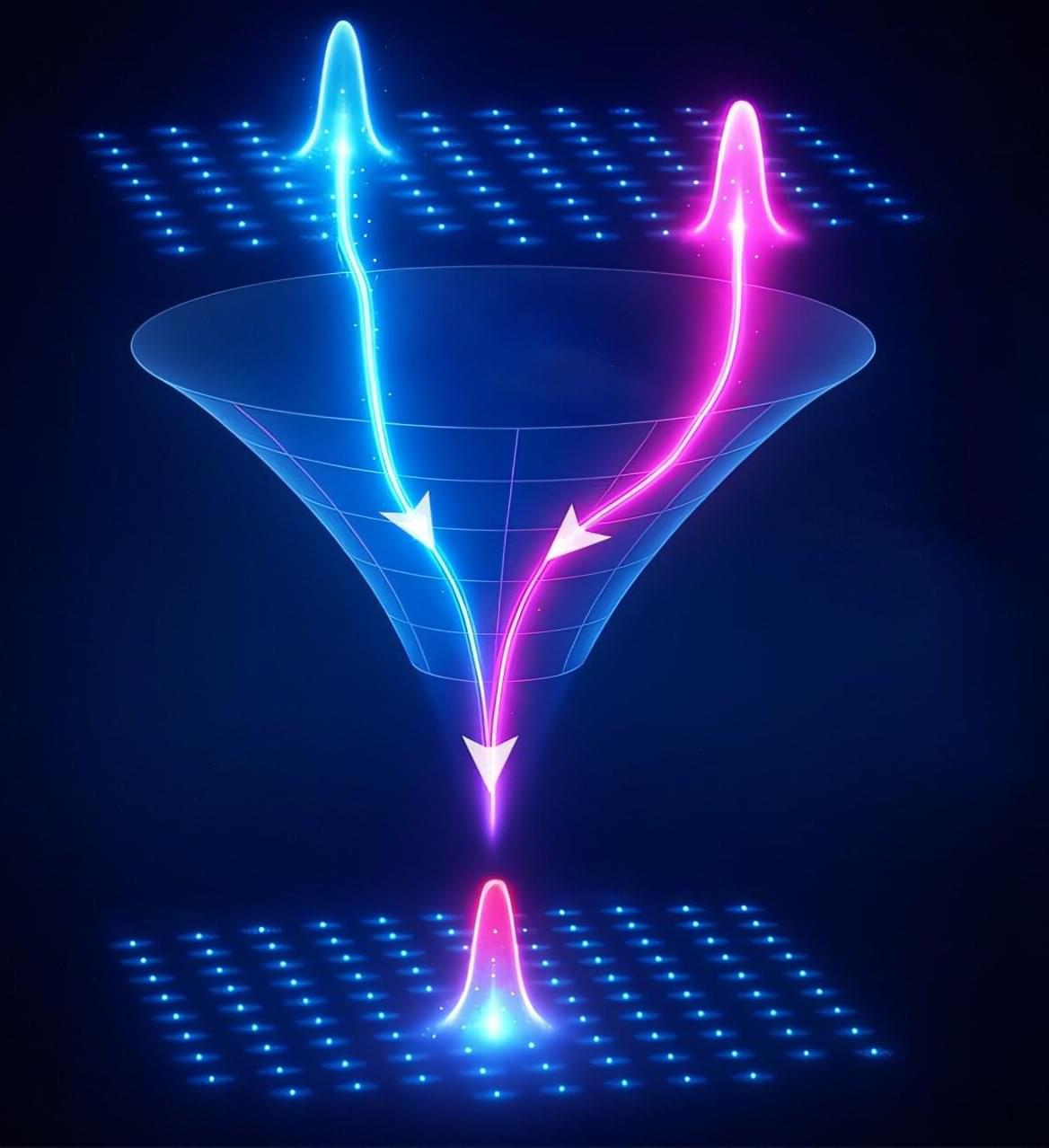

Researchers led by James Tour, the T.T. and W.F. Chao Professor of Chemistry and professor of materials science and nanoengineering at Rice University, have developed a faster and cleaner method using flash Joule heating (FJH). This technique rapidly heats materials to thousands of degrees within milliseconds and works in conjunction with chlorine gas, exposing the rock to intense heat and chlorine gas, they can quickly convert spodumene ore into usable lithium.