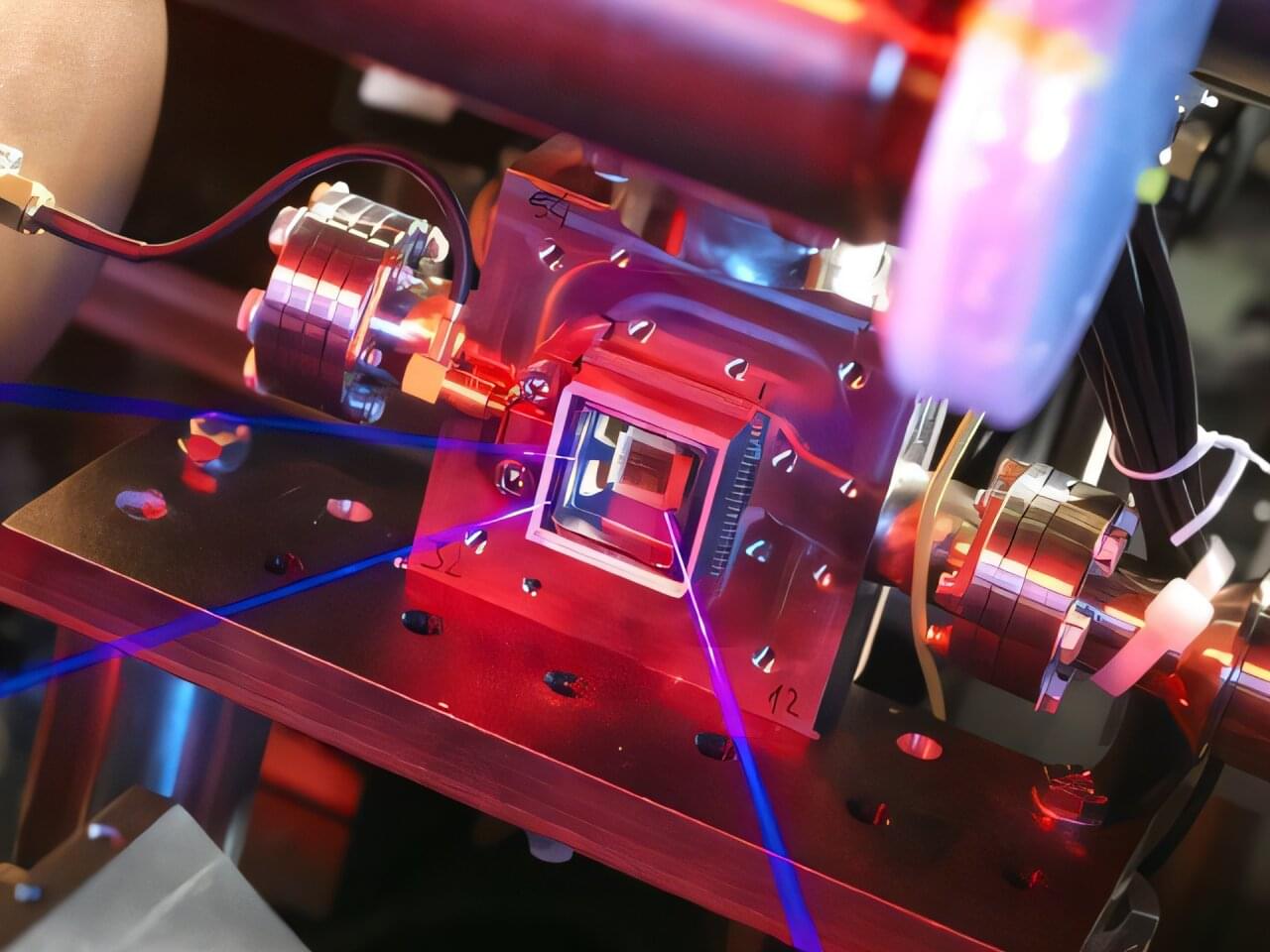

In a new study published in Physical Review Letters, scientists have estimated a new lower bound on the mass of ultra-lightweight bosonic dark matter particles.

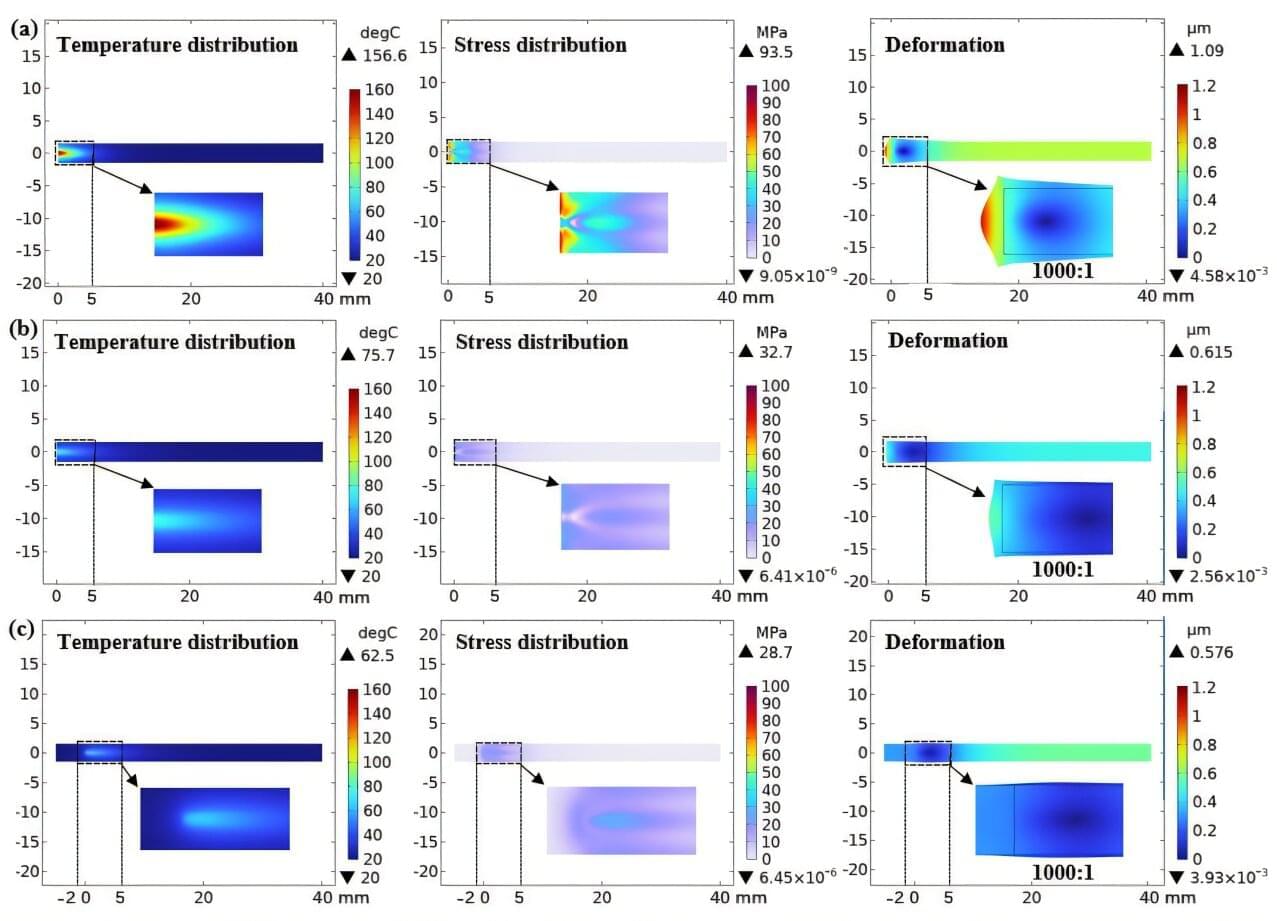

In recent research published in Optics & Laser Technology and Infrared Physics & Technology, a research team led by Prof. Cheng Tingqing at the Hefei Institutes of Physical Science of the Chinese Academy of Sciences has introduced a novel low-thermal-effect gradient-doped crystal to tame thermal effects and improve the brightness of high-power end-pumped Nd: YAG lasers.

Traditional end-pumped solid-state lasers rely on uniformly doped crystals, which develop significant temperature gradients and thermal stresses under high pump power due to the axial absorption decay of pump power. These effects not only limit maximum pump power, but also degrade beam quality and conversion efficiency.

In this study, the researchers devised a numerical model for crystals whose neodymium concentration gradually increases along the rod, providing a theoretical basis for optimizing the concentration distribution and growth of novel gradient-doped crystals.

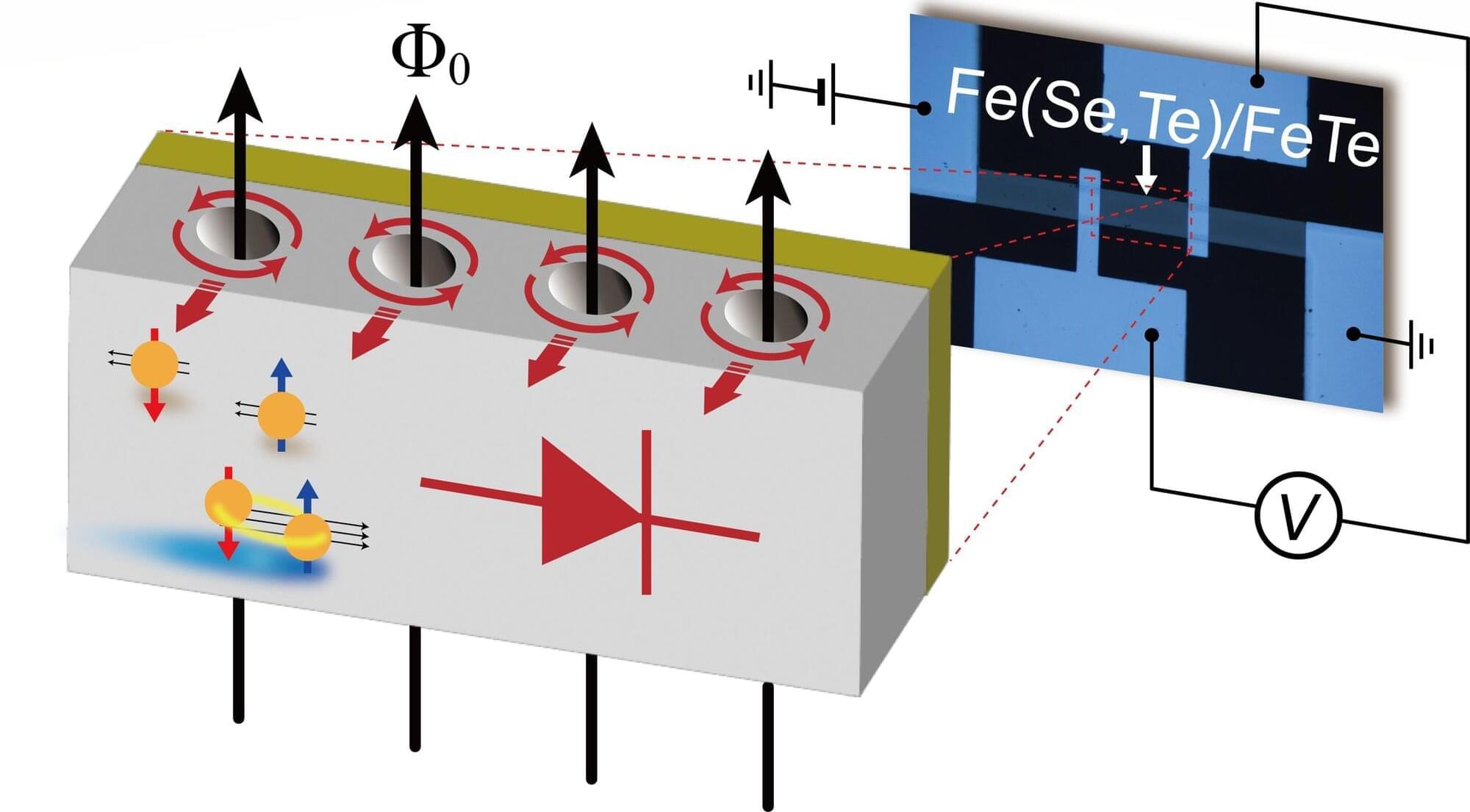

What would happen if you combined the unparalleled efficiency of a superconductor with the flexibility and controllability of a semiconductor? Thanks to a new breakthrough in quantum materials, we may be getting an answer soon.

In an article published in Communications Physics, a multi-institutional research team led by The University of Osaka announces the successful observation of the so-called superconducting diode effect in an Fe(Se, Te)/FeTe heterostructure. The paper is titled “A scaling relation of vortex-induced rectification effects in a superconducting thin-film heterostructure.”

The article describes a series of experiments in which the material developed a preference for current to flow in a particular direction, a phenomenon known as rectification, under a broad range of temperature and magnetic fields.

The findings are published in the journal Physical Review Letters.

Compared with their classical counterparts, systems made up of many quantum particles—such as quantum computers—are horrendously complex to analyze and simulate. This complexity is due in part to the strong correlations between particles, which can act over long distances.

In the future, quantum technology will become the standard for extremely fast computers. These kinds of machines will be important in everything from space technology to mineral exploration and the development of new medicines.

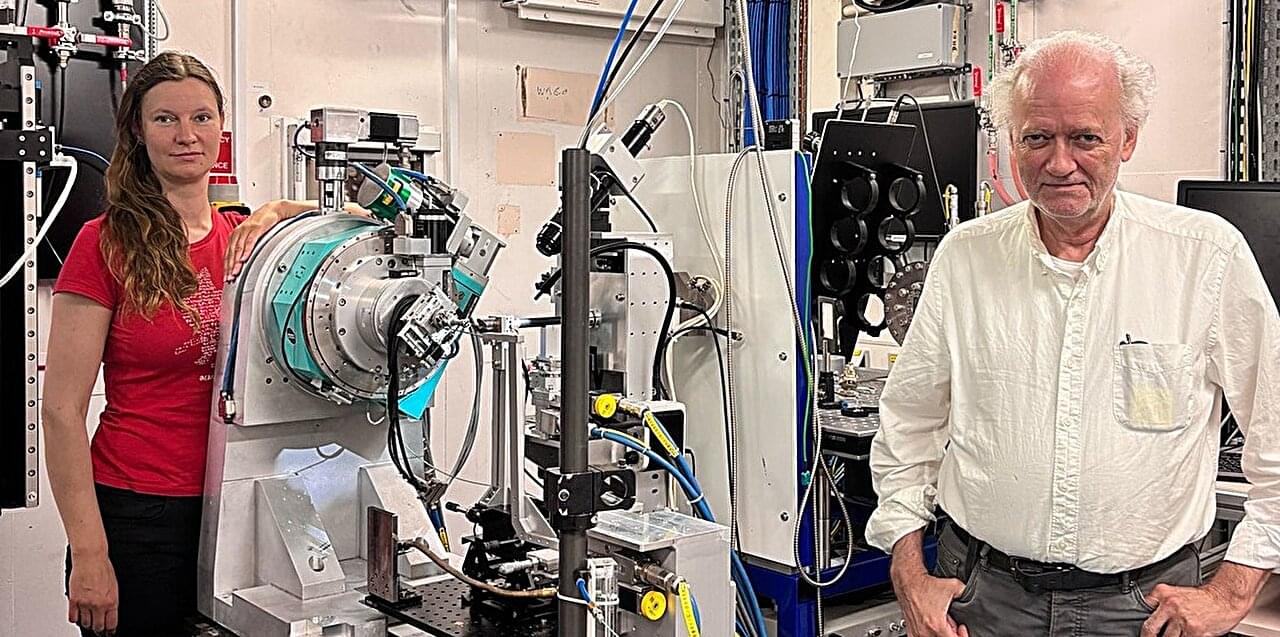

“Quantum technology is often associated with synthetic materials that have been developed in advanced, completely clean environments,” says Professor Jon Otto Fossum from NTNU’s Department of Physics.

But Fossum and colleagues have good news.

This material can expand, change shape, move, and respond to electromagnetic commands like a remotely controlled robot, even though it has no motor or internal gears. In a study that echoes scenes from the Transformers movie franchise, engineers at Princeton University have developed a material c

We know water in its solid state — ice — exists on moons orbiting Jupiter, Saturn, Uranus, and Neptune. Telescopes have also spotted frozen water on dwarf planets, comets, and other bits of rock that “hang out” in the Kuiper Belt at the edge of our solar system. But for decades, water ice was not confirmed to exist around other stars.

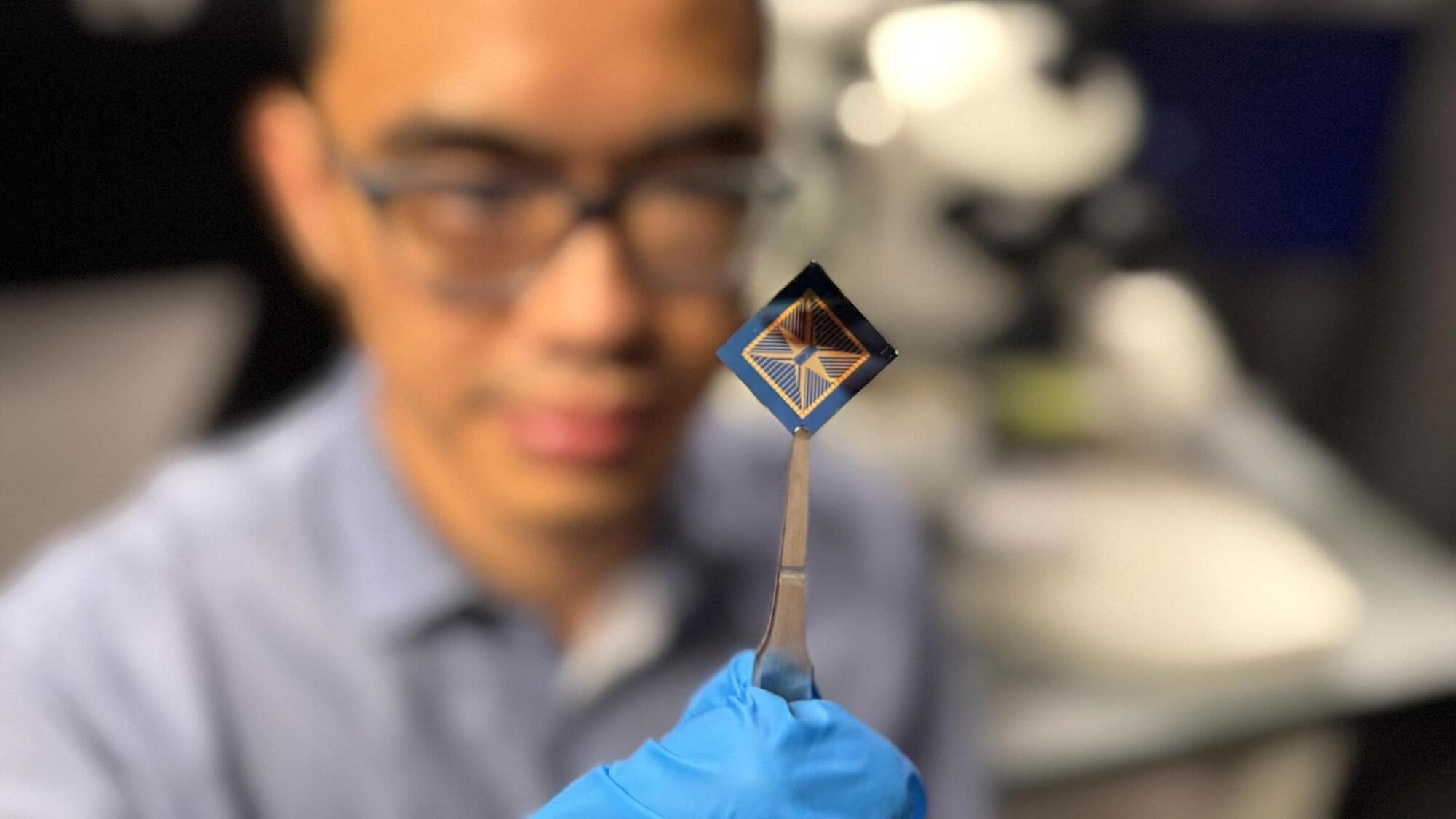

The James Webb Space Telescope has unequivocally changed that: Data from its NIRSpec (Near-Infrared Spectrograph) confirmed the presence of water ice in a dusty debris disk that surrounds a star known as HD 181327.

Water ice heavily influences the formation of giant planets and may also be delivered by comets to fully formed rocky planets. Now that researchers have detected water ice with Webb, they have opened the door to studying how these processes play out in new ways — in many other planetary systems — for all researchers.

“These neurons are playing an outsized role in hyperglycemia and type 2 diabetes,” said UW Medicine endocrinologist Dr. Michael Schwartz, corresponding author of the paper.

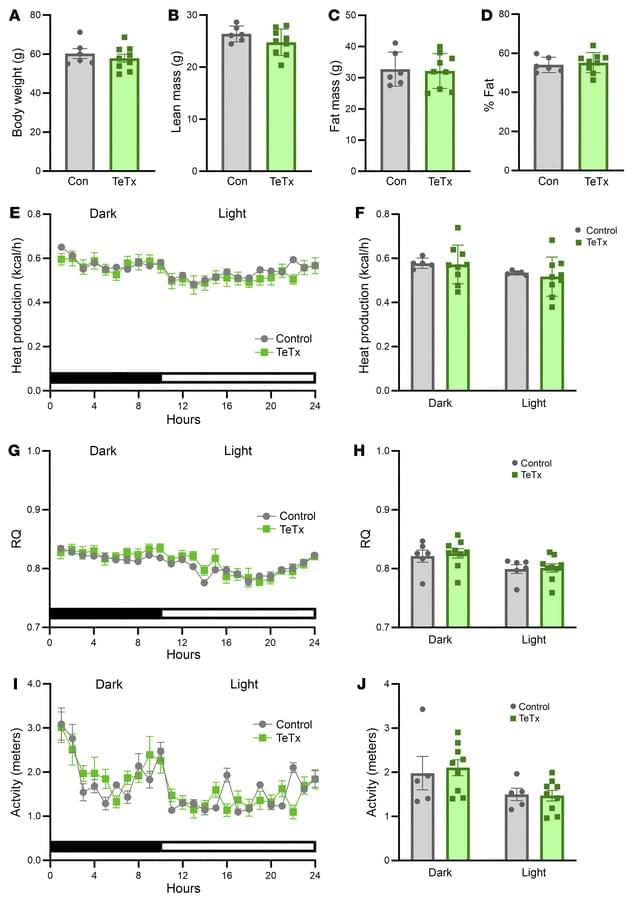

To determine if these neurons contribute to elevated blood sugar in diabetic mice, researchers employed a widely used viral genetics approach to make AgRP neurons express tetanus toxin, which prevents the neurons from communicating with other neurons.

Unexpectedly, this intervention normalized high blood sugar for months, despite having no effect on body weight or food consumption.

Conventional wisdom is that diabetes, particularly type 2 diabetes, stems from a combination of genetic predisposition and lifestyle factors, including obesity, lack of physical activity and poor diet. This mix of factors leads to insulin resistance or insufficient insulin production.

Until now, scientists have traditionally thought the brain doesn’t play a role in type 2 diabetes, according to Schwartz.

The paper challenges this and is a “departure from the conventional wisdom of what causes diabetes,” he said.

The new findings align with studies published by the same scientists showing that injection of a peptide called FGF1 directly into the brain also causes diabetes remission in mice. This effect was subsequently shown to involve sustained inhibition of AgRP neurons.