A Cork scientist has played a leading role in developing dissolvable brain implants.

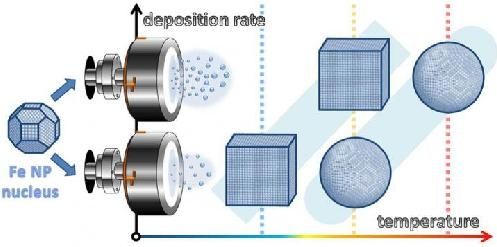

The efficiency of many applications deriving from natural sciences depends dramatically on a finite-size property of nanoparticles, so-called surface-to-volume ratio. The larger the surface of nanoparticles for the same volume is achieved, the more efficiently nanoparticles can interact with the surrounding substance. However, thermodynamic equilibrium forces nanostructures to minimize open surface driven by energy minimization principle. This basic principle predicts that the only shape of nanoparticles can be spherical or close-to-spherical ones.

Nature, however, does not always follow the simple principles. An intensive collaboration between University of Helsinki, Finland, and Okinawa Institute of Science and Technology, Japan, showed that in some condition iron nanoparticles can grow in cubic shape. The scientists also succeeded in disclosing the mechanisms behind this.

“Now we have a recipe how to synthesize cubic shapes with high surface-to-volume ratio which opens the door for practical applications”, says Dr. Flyura Djurabekova from the University of Helsinki.

Israel must remain on the cutting edge of cyber-defense, –security and –technology in order to maintain the safety and security of the state, Prime Minister Benjamin Netanyahu wrote in Globes on Sunday.

In the article, Netanyahu outlined his vision, policies and initiatives aimed at arming the Jewish state with the latest in “cybernetic innovation.” According to the Israeli leader, “Cyber defense is an essential condition for national security and economic growth in the 21st century,” and Israel’s strength in the fields of science and technology is leading the country to be one of the world’s greatest “cyber security power.”

“Five years ago, I set the goal of making Israel one of the five leading global cyber powers. We are already placed very high, and the world regards us as a rising power. Enhancing our capabilities in the cyber field requires continuous effort,” Netanyahu wrote.

I see both positive and many negatives to this. Anything available to pharmacies, etc. is also retrievable by cartels.

A continuous-flow method to synthesize medicine promises to change how pharmaceuticals are produced and used.

By Bob Roehr on April 1, 2016.

ANNAPOLIS, Md. (April 15,2015) U.S. Naval Academy Midshipmen work together during last year’s Cyber Defense Exercise hosted by the National Security Agency. A new report from the Government Accountability Office finds the Defense Department’s chain of command is unclear for responding to domestic cyber attacks. (U.S. Navy photo by Mass Communications Specialist 2nd Class Tyler Caswell/RELEASED)(Photo: Navy Media Content Services)

Artificial molecules

Posted in 3D printing, materials

Scientists at ETH Zurich and IBM Research Zurich have developed a new technique that enables for the first time the manufacture of complexly structured tiny objects joining together microspheres. The objects have a size of just a few micrometres and are produced in a modular fashion, making it possible to program their design in such a way that each component exhibits different physical properties. After fabrication, it is also very simple to bring the micro-objects into solution. This makes the new technique substantially different from micro 3D printing technology. With most of today’s micro 3D printing technologies, objects can only be manufactured if they consist of a single material, have a uniform structure and are attached to a surface during production.

To prepare the micro-objects, the ETH and IBM researchers use tiny spheres made from a polymer or silica as their building blocks, each with a diameter of approximately one micrometre and different physical properties. The scientists are able to control the particles and arrange them in the geometry and sequence they like.

The structures that are formed occupy an interesting niche in the size scale: they are much larger than your typical chemical or biochemical molecules, but much smaller than typical objects in the macroscopic world. “Depending on the perspective, it’s possible to speak of giant molecules or micro-objects,” says Lucio Isa, Professor for Interfaces, Soft matter and Assembly at ETH Zurich. He headed the research project together with Heiko Wolf, a scientist at IBM Research. “So far, no scientist has succeeded in fully controlling the sequence of individual components when producing artificial molecules on the micro scale,” says Isa.