Houston, we’ve got mice.

20 astronaut mice en route to the International Space Station (ISS) could shed light on the effect on long-term space exposure on the human body.

Some market observers worry the solutions to problems the new technologies offer might become the causes of other problems. With AI gathering steam and large amounts of data flowing to empower machine learning, how to protect privacy in a region where the use of personal information is loosely regulated has become a pressing question.

Filing taxes using blockchain in Indonesia. Growing better crops in Vietnam with artificial intelligence. Sending rockets into space in Singapore. Southeast Asia is quietly emerging as a breeding ground for new technology.

“The countries which have the capacity to bring that source from the moon to Earth will dictate the process,” said K Sivan, chairman of the Indian Space Research Organisation (ISRO). “I don’t want to be just a part of them, I want to lead them.”

The mission would solidify India’s place among the fleet of explorers racing to the moon, Mars and beyond for scientific, commercial or military gains. The governments of the US, China, India, Japan and Russia are competing with startups and billionaires Elon Musk, Jeff Bezos and Richard Branson to launch satellites, robotic landers, astronauts and tourists into the cosmos.

The rover landing is one step in an envisioned series for ISRO that includes putting a space station in orbit and, potentially, an Indian crew on the moon. The government has yet to set a timeframe.

MyDefence is launching PITBULL – a next generation wearable Counter UAS solution utilizing smart jamming to defeat enemy drones. PITBULL is developed to have minimal impact on other signals while jamming, in an effort to maintain own communication. The Counter UAS jammer weighs 775 grams and can be worn on the uniform.

We come in peace.

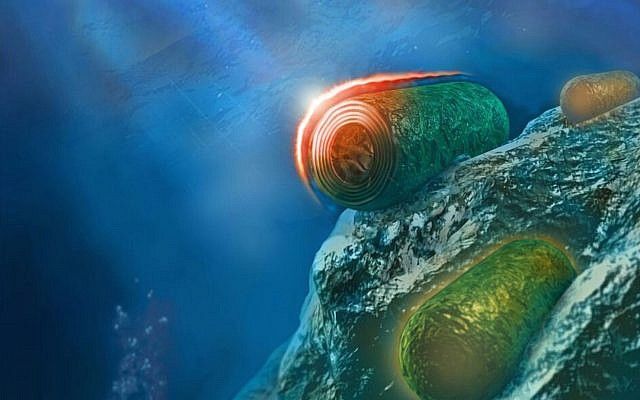

You can generate electricity from oil, you can produce it from natural gas, you can make it from nuclear energy, and you can channel it from the sun, via solar energy conversion systems. You can even generate electricity from photosynthetic bacteria, also known as cyanobacteria, based on a new innovation developed at the Technion. As published in a study in the journal, Nature Communications, the Technion researchers have developed an energy-producing system that exploits both the photosynthesis and respiratory processes that cyanobacteria undergo, with the harvested energy leveraged to generate electricity based on hydrogen.

The study was conducted by three Technion faculty members: Professor Noam Adir from the Schulich Faculty of Chemistry, Professor Gadi Schuster from the Faculty of Biology, and Professor Avner Rothschild, from the Faculty of Materials Science and Engineering. The work involved collaboration between Dr. Gadiel Saper and Dr. Dan Kallmann, as well as colleagues from Bochum, Germany and the Weizmann Institute of Science. It was supported by various bodies, including the Nancy and Stephen Grand Technion Energy Program (GTEP), the Russell Berrie Nanotechnology Institute (RBNI), the Technion Hydrogen Technologies Research Lab (HTRL), the Adelis Foundation, the Planning and Budgeting Committee’s I-CORE program, the Israel Science Foundation, the USA-Israel Binational Science Fund (BSF) and the German research fund (DFG-DIP).

Scientists have long considered cyanobacteria a possible energy source. Cyanobacteria belong to a family of bacteria common to lakes, seas, and many other habitats. The bacteria use photosynthetic mechanisms that enable them to generate energy from sunlight. They also generate energy in the dark, via respiratory mechanisms based on digestion and degradation of sugar.