The privately funded Fram2 mission is the first ever to take astronauts into polar orbit—and the latest sign of a “new normal” for human spaceflight.

By Lee Billings edited by Dean Visser.

The privately funded Fram2 mission is the first ever to take astronauts into polar orbit—and the latest sign of a “new normal” for human spaceflight.

By Lee Billings edited by Dean Visser.

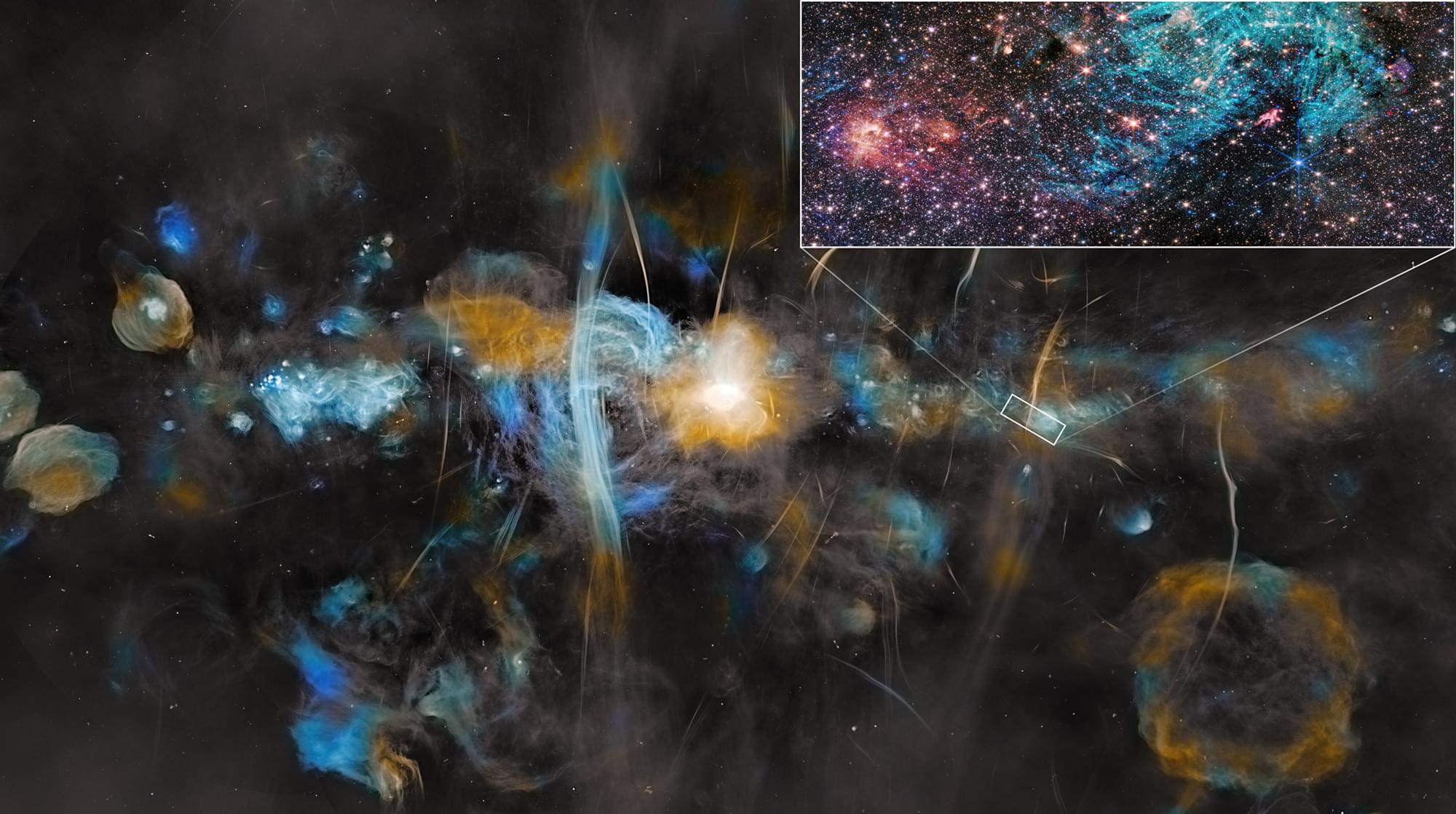

Follow-up research on a 2023 image of the Sagittarius C stellar nursery in the heart of our Milky Way galaxy, captured by NASA’s James Webb Space Telescope, has revealed ejections from still-forming protostars and insights into the impact of strong magnetic fields on interstellar gas and the life cycle of stars.

“A big question in the Central Molecular Zone of our galaxy has been, if there is so much dense gas and cosmic dust here, and we know that stars form in such clouds, why are so few stars born here?” said astrophysicist John Bally of the University of Colorado Boulder, one of the principal investigators. “Now, for the first time, we are seeing directly that strong magnetic fields may play an important role in suppressing star formation, even at small scales.”

Detailed study of stars in this crowded, dusty region has been limited, but Webb’s advanced near-infrared instruments have allowed astronomers to see through the clouds to study young stars like never before.

“No two ways about it,” Altepeter told Breaking Defense today. “The number of companies that we’re announcing is a surprise to me. I did not expect we would get this many.”

For the winning teams, the value of QBI is not just the money. Indeed, first-round grants like those being announced today have typically been under $1 million — small change not just for the Pentagon but for tech firms and venture capitalists already investing billions into quantum ventures. We suggested everybody apply for a million, [but] some people came in and said they were going to do it for less, Altepeter said.

The unique value of a QBI award is that it gives the winning companies access to a DARPA-led team of quantum experts, pulled from both US government labs, including the famous Los Alamos, and federally funded research institutions. Their job is to act as independent testers, fresh eyes, and devil’s advocates, rigorously scrutinizing each participant’s quantum strategy.

A trio of US researchers claim to have successfully tested predictions that it’s possible to harvest clean energy from the natural rhythms and processes of our planet, generating electricity as Earth rotates through its own magnetic field.

Though the voltage they produced was tiny, the possibility could give rise to a new way to generate electricity from our planet’s dynamics, alongside tidal, solar, wind, and geothermal power production.

In 2016, Princeton astrophysicist Christopher Chyba and JPL planetary scientist Kevin Hand challenged their own proof that such a feat ought to be impossible. The researchers have now uncovered empirical evidence that their proof-breaking idea may actually work, as long as the shape and properties of the conducting material in their method are set to very specific requirements.

ABSTRACT. Seismic waves carry rich information about earthquake sources and the Earth’s medium. However, the process of extracting earthquake source parameters from seismic waves using traditional methods is complex and time consuming. In this study, we present a deep‐learning‐based method for automatic determination of earthquake source parameters. Considering the principle of calculating source parameters, the input of the deep neural network (SourceNet) includes not only the seismic waveform, but also the amplitude, epicenter distance, and station information. The utilization of multimodal data significantly improves the accuracy of determining earthquake source parameters. The test results using the real seismic data in the Sichuan–Yunnan region show that the earthquake source parameters obtained by SourceNet are in good agreement with the manual results and have higher computational efficiency. We apply the trained SourceNet to the seismic activities in the Changning area and further verify the reliability of the method by comparing our estimates of stress drops with those reported in previous studies of this area. The average time for SourceNet to calculate the source parameters of an earthquake is less than 0.1 s, which can be used for real‐time automatic determination of source parameters.

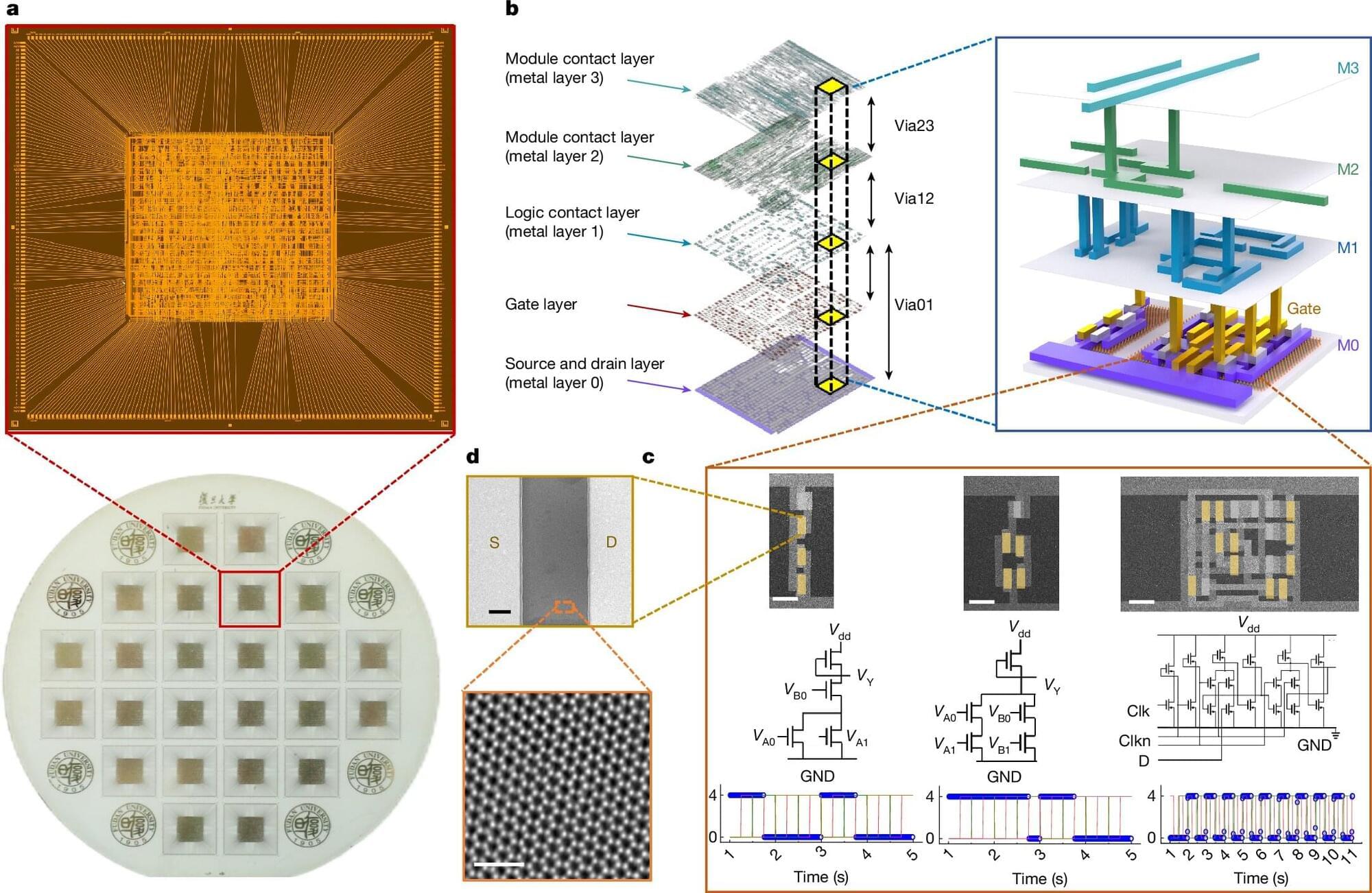

A team of engineers at Fudan University has successfully designed, built and run a 32-bit RISC-V microprocessor that uses molybdenum disulfide instead of silicon as its semiconductor component. Their paper is published in the journal Nature.

Most microprocessors are made using the semiconductor silicon, which has worked out well for several decades. But as researchers attempt to make processors ever smaller, they have run into a dead end with silicon—they cannot make it any thinner. Instead, many researchers have turned to 2D materials such as graphene, but this is challenging because it is a conductor, not a semiconductor.

In this new study, the research team used a nearly 2D semiconducting material, single-molecule sheets of molybdenum disulfide. These sheets are not truly 2D because they bond at an angle, resulting in a slightly zigzag surface. To make a processor out of them, they put them on a sapphire substrate.