An Australian company is the first customer for an external research platform Airbus Defence and Space plans to install on the space station by 2018.

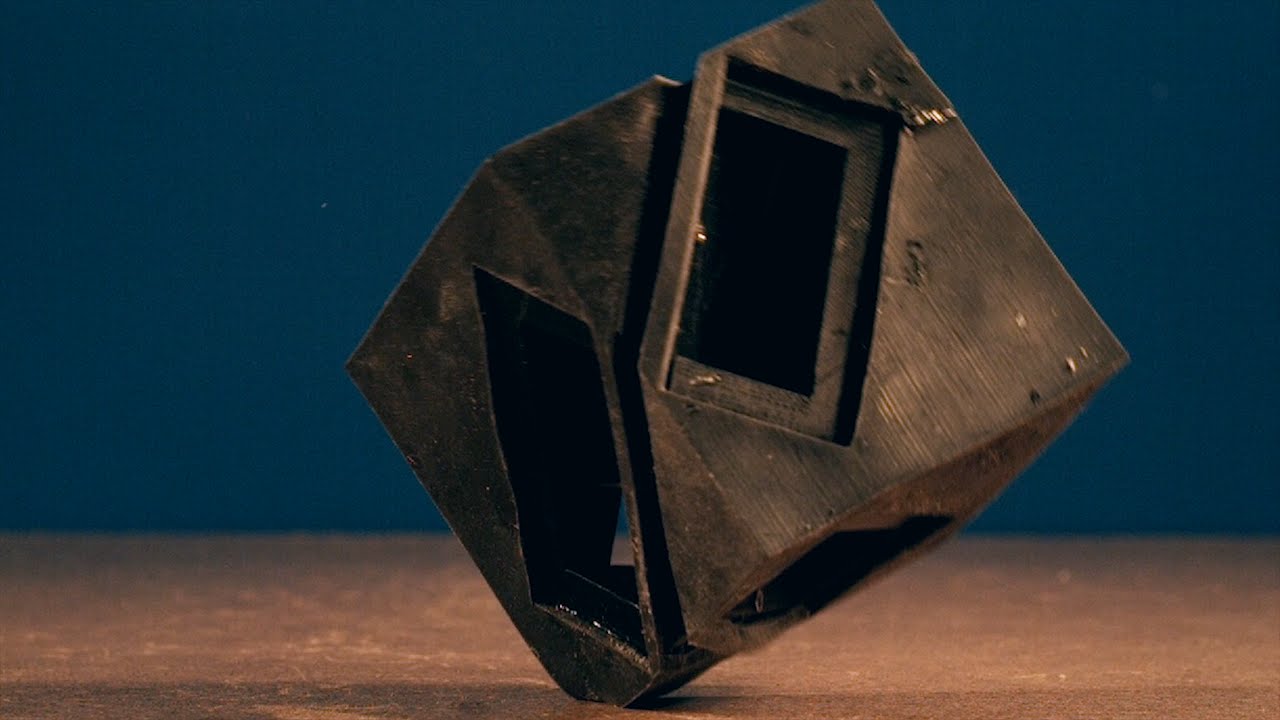

Spectators of the DARPA Robotics Challenge finals in 2015 would have noticed that many of the competing robots were padded up for protection in case they took a tumble. MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) is looking to build customizable shock-absorbing protection into robots by using 3D printing to produce soft materials that not only dampen the impact of falls, but also allows them to carry out safer, more precise movements.

Robotics engineers have long had a keen interest in soft materials. At their simplest, such materials can protect robots against falls and collisions, but can also protect people in environments were robots and humans are increasingly working together. Going beyond this, soft materials also allow for making completely soft robots that can mimic animal design.

Using 3D printing technology, CSAIL is creating soft materials that can change the basic capabilities of the robot. Called programmable viscoelastic material (PVM), it’s based on the idea of controlling the stiffness and elasticity of a substance to change how it moves and responds. In this way, engineers can tailor the material for the task at hand.

As useful as they are, wearable fitness trackers aren’t usually the height of fashion themselves, with many devices blending away out of sight on your wrist or ankle. Now Intel and Luxottica have teamed up to put a fitness tracker front and center on your face, stashing various biometric sensors and a voice-activated AI coach into a stylish, custom-designed pair of Oakley shades.

Smarter thread

Posted in biotech/medical, chemistry, computing, health, mobile phones, nanotechnology

I never get tired in circuitry thread and any new findings.

Tufts University engineers say that revolutionary health diagnostics may be hanging on a thread—one of many threads they have created that integrate nano-scale sensors, electronics and microfluidics into threads ranging from simple cotton to sophisticated synthetics. “We think thread-based devices could potentially be used as smart sutures for surgical implants, smart bandages to monitor wound healing, or integrated with textile or fabric as personalized health monitors and point-of-care diagnostics,” says Sameer Sonkusale, Ph.D., director of the interdisciplinary Nano Lab in the Department of Electrical and Computer Engineering at Tufts School of Engineering, Medford/Somerville, Mass.

Researchers dipped a variety of conductive threads in physical and chemical sensing compounds and connected them to wireless electronic circuitry. The threads, sutured into tissues of rats, collected data on tissue health (pressure, stress, strain and temperature), pH and glucose levels. The data helps determine how wounds are healing, whether infection is emerging or whether the body’s chemistry is out of balance. Thread’s natural wicking properties draw fluids to the sensing compounds. Resulting data is transmitted wirelessly to a cell phone and computer.

To date, substrates for implantable devices have been two-dimensional, expensive and difficult to process, making them suitable for flat tissue, such as skin, but not for organs. “By contrast, thread is abundant, inexpensive, thin and flexible, and can be easily manipulated into complex shapes,” says Pooria Mostafalu, Ph.D., postdoctoral research fellow with the Harvard-MIT Division of Health Sciences and Technology and former Tufts doctoral student.

“Wind power has transformed the heart of fossil-fuel country. Can the rest of the United States follow suit?”

In 2009, Carbon nanotube tethers with a strength of 9 N/Tex [9 million newton meters/kg] is over twice as strong as any fibers ever produced before.

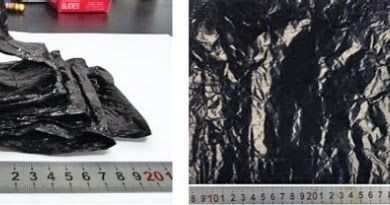

In 2016, Jian Nong Wang and his colleagues made nanotubes with a process akin to glass blowing: Using a stream of nitrogen gas, they injected ethanol, with a small amount of ferrocene and thiophene added as catalysts, into a 50-mm-wide horizontal tube placed in furnace at 1,150–1,130 °C.

They packed the nanotubes even more densely by pressing the film repeatedly between two rollers.

My new story for TechCrunch on why a new generation of kids might “really” love robots. What would Freud say?

Robots intrigue us. We all like them. But most of us don’t love them. That may dramatically change over the next 10 years as the “robot nanny” makes its way into our households.

In as little time as a decade, affordable robots that can bottle-feed babies, change diapers and put a child to sleep might be here. The human-machine bond that a new generation of kids grows up with may be unbreakable. We may end up literally loving our machines almost like we do our mothers and fathers.

I’ve already seen some of this bonding in action. I have a four-foot interactive Meccanoid robot aboard my Immortality Bus, which I’ve occasionally used for my presidential campaign. The robot can do about 1,000 functions, including basic interaction with people, like talking, answering questions and making wisecracks. When my five-year-old rides with me on the bus, she adores it. After being introduced to it, she obsessively wanted to watch Inspector Gadget videos and read books on robots.

More progress in repairing damage to the cornea which could have implications for aging research as well as for injury.

Media Contacts: Suzanne Day Media Relations, Mass. Eye and Ear 617−573−3897 [email protected]

New findings may pave the way for the development of pharmaceutical therapies to reverse corneal scarring

Boston, Mass. — In cases of severe ocular trauma involving the cornea, wound healing occurs following intervention, but at the cost of opaque scar tissue formation and damaged vision. Recent research has shown that mesenchymal stem cells (MSCs) — which can differentiate into a variety of cells, including bone, cartilage, muscle and fat cells — are capable of returning clarity to scarred corneas; however, the mechanisms by which this happens remained a mystery — until now. In a study published online today in Stem Cell Reports, researchers from Schepens Eye Research Institute of Massachusetts Eye and Ear have identified hepatocyte growth factor (HGF), secreted by MSCs, as the key factor responsible for promoting wound healing and reducing inflammation in preclinical models of corneal injury. Their findings suggest that HGF-based treatments may be effective in restoring vision in patients with severely scarred corneas.