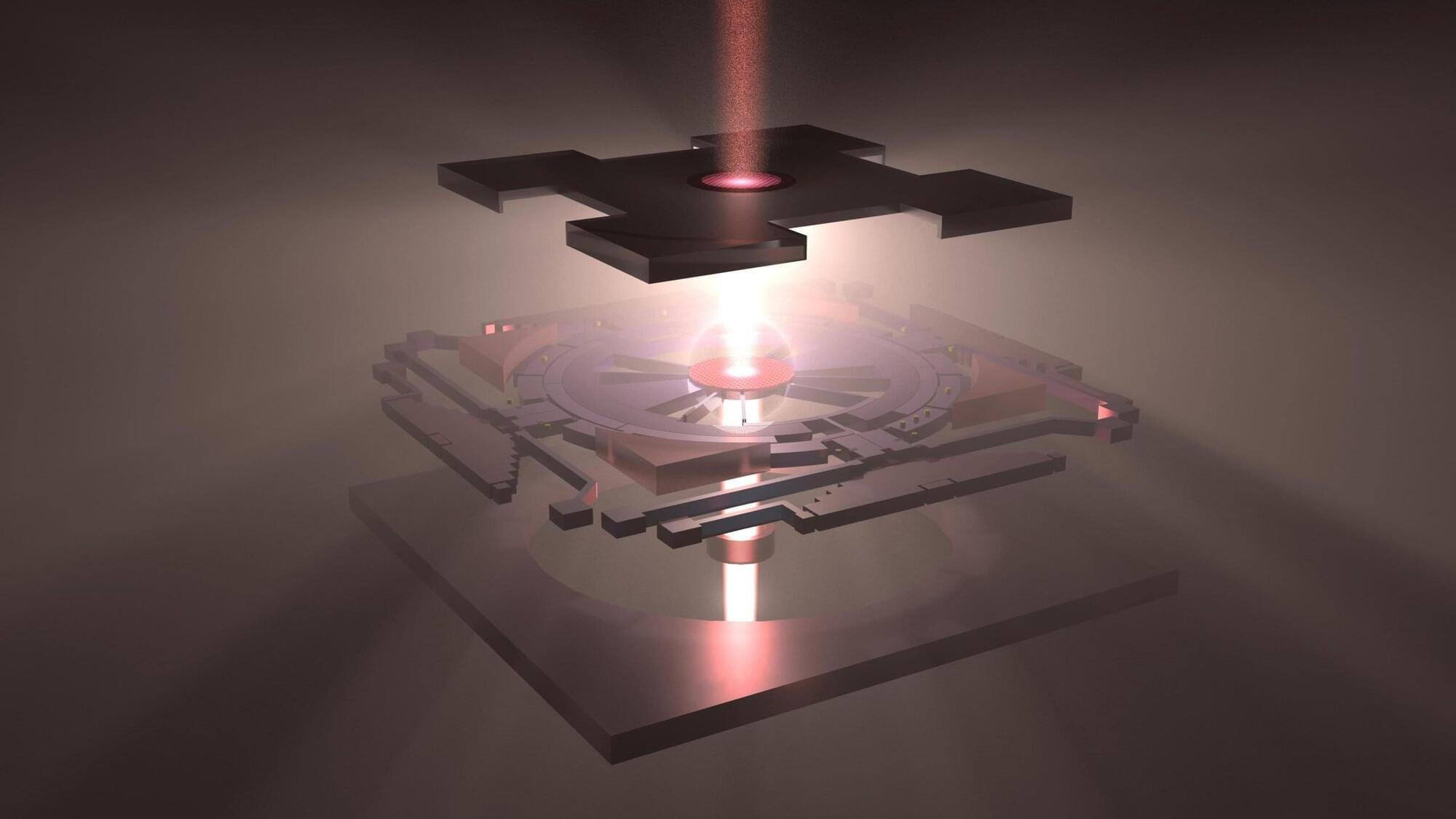

Q.ANT announces production of its revolutionary light-powered AI chip, promising 50x faster speeds and 30x better energy efficiency.

IN A NUTSHELL 🚀 Pulsar Fusion is developing the Sunbird, a fusion-powered rocket, to significantly reduce interplanetary travel times by 2027. 🔬 The Sunbird uses a Duel Direct Fusion Drive (DDFD) engine, promising unprecedented exhaust speeds and efficiency. 🛰️ The rocket will operate as a space “tugboat,” stationed in orbital satellite docks for missions to

When the International Maritime Organization enacted a mandatory cap on the sulfur content of marine fuels in 2020, with an eye toward reducing harmful environmental and health impacts, it left shipping companies with several main options.

They could burn low-sulfur fossil fuels, like marine gas oil, or install cleaning systems to remove sulfur from the exhaust gas produced by burning heavy fuel oil. Biofuels with lower sulfur content offer another alternative, though their limited availability makes them a less feasible option.

While installing exhaust gas cleaning systems, known as scrubbers, is the most feasible and cost-effective option, there has been a great deal of uncertainty among firms, policymakers, and scientists as to how “green” these scrubbers are.

Researchers at EPFL have found a way to dramatically reduce energy loss and boost efficiency in perovskite solar cells by incorporating rubidium using lattice strain—a slight deformation in the atomic structure that helps keep rubidium in place.

Solar energy is one of the most promising solutions for reducing our dependence on fossil fuels. But making solar panels more efficient is a constant challenge. Perovskite solar cells (PSCs) have been a game-changer, offering rapid improvements in efficiency and potential for low-cost manufacturing. However, they still suffer from energy losses and operational stability issues.

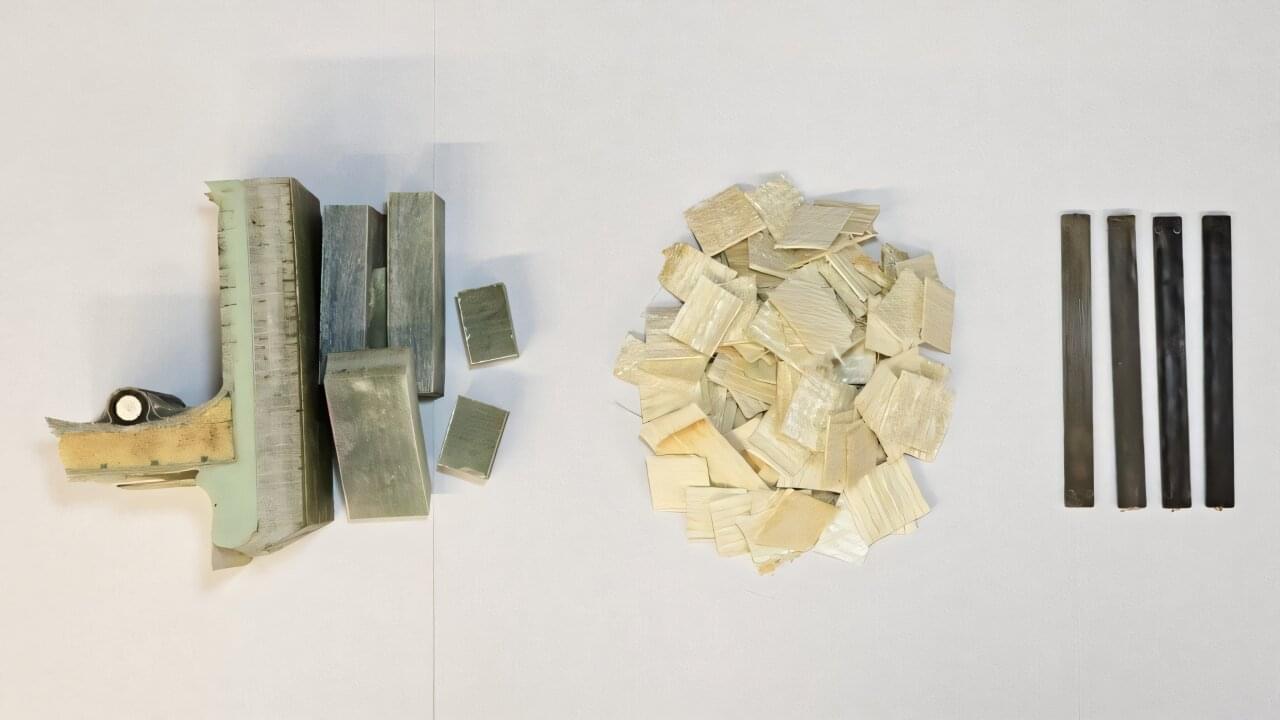

A new method to recycle wind turbine blades without using harsh chemicals resulted in the recovery of high-strength glass fibers and resins that allowed Washington State University researchers to repurpose the materials to create stronger plastics.

The innovation provides a simple and environmentally friendly way to recycle wind turbine blades to create useful products.

Reporting in the journal, Resource, Conservation, and Recycling, the team of researchers cut the lightweight material that is commonly used in wind turbine blades, called glass fiber-reinforced polymer (GFRP), into approximately two inch-sized blocks. They then soaked the flakes in a bath of low-toxicity organic salt in pressurized, superheated water for about two hours to break down the material. They then repurposed its components to make stronger plastics.