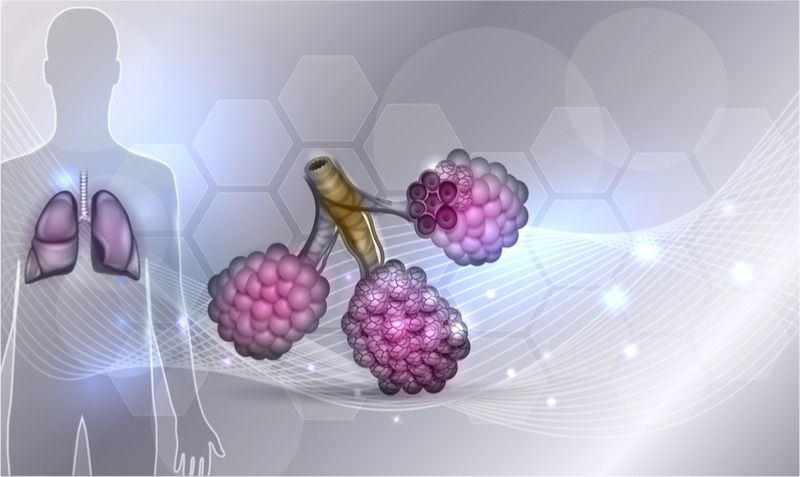

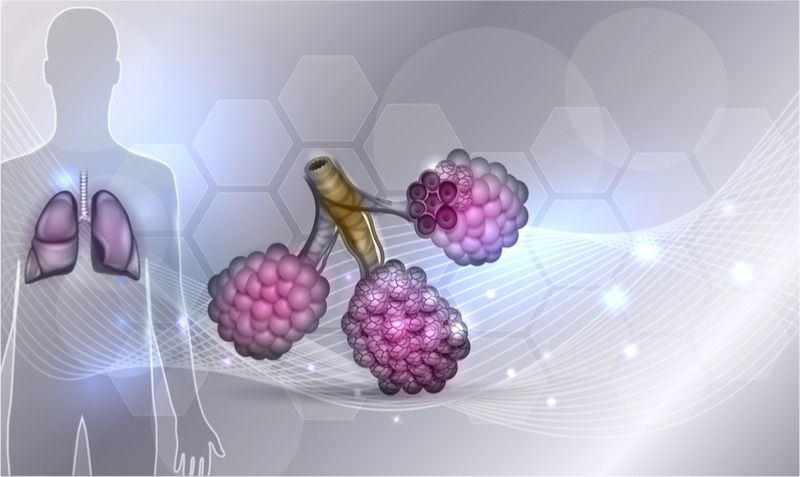

The results from a human pilot study that focused on treating idiopathic pulmonary fibrosis with senescent cell-clearing drugs has been published. The drugs target aged and damaged cells, which are thought to be a reason we age and get sick, and remove them from the body.

Senescent cells and aging

As we age, increasing numbers of our cells become dysfunctional, entering into a state known as senescence. Senescent cells no longer divide or support the tissues and organs of which they are part; instead, they secrete a range of harmful inflammatory chemical signals, which are collectively known as the senescence-associated secretory phenotype (SASP).

Read more