Quick media feed on tech, culture, innovators, design and more.

Donate to help us…

Quick media feed on tech, culture, innovators, design and more.

Donate to help us…

What should Donald Trump have NASA do? Today Amazon billionaire Jeff Bezos voiced his support for the idea that the space agency should help build a “highway in the sky” analogous to the interstate highway system that President Dwight Eisenhower ramped up in the 1950s.

The backing came in the form of an eight-word tweet, accompanied by a link to an article by Howard Bloom appearing in Salon (and as a guest blog posting on Scientific American’s website as well).

In Brief

Automotive company Kawasaki Heavy Industries, Ltd. (KHI) is developing next-generation motorcycles with an AI controlled-system that not only ensures safer rides, but also develops an emotional connection with the user.

The bikes use a system called the “Emotion Generation Engine and Natural Language Dialogue System”, developed by robotics teams from cocoro SB Corp. The driver can talk to the bike and it will be able to pick up cues on the rider’s emotional state and intents. In their press release, Kawasaki said that this “will open the door to a new world of unprecedented riding experiences.”

Tiny electric airplanes could transform air travel.

On its own, swapping conventional aircraft engines for electric motors could have significant benefits, reducing the cost of air travel and emissions per flight. But the bigger opportunity here is to make air travel practical in situations where no one would think to take an airplane today.

Back in October, Uber published a white paper describing its vision of the future small VTOL aircraft could make possible. Uber envisions a network of on-demand aircraft carrying passengers among many landing spots distributed throughout a metropolitan area. For example, right now it takes at least an hour to drive from San Jose, California, to San Francisco — and closer to two hours during rush hour. In contrast, Uber estimates, the same trip could take 15 minutes in a VTOL airplane.

I must see this. Wonder if anyone will try glide off the bridge with a wingsuit?

The world’s highest bridge has opened to traffic in China, connecting two provinces in the mountainous southwest and reducing travel times by as much as three-quarters, local authorities said Friday.

The Beipanjiang Bridge soars 565 metres (1,854 feet) above a river and connects the two mountainous provinces of Yunnan and Guizhou, the Guizhou provincial transport department said in a statement on its official website.

The bridge cut travel times between Xuanwei in Yunnan to Shuicheng in Guizhou from more than four hours to around one, a truck driver surnamed Duan was quoted by the official news agency Xinhua as saying after the bridge opened Thursday. It was “very convenient for people who want to travel between these two places”, he added.

When you engage in international travel, you may one day find yourself face-to-face with border security that is polite, bilingual and responsive—and robotic.

The Automated Virtual Agent for Truth Assessments in Real Time (AVATAR) is currently being tested in conjunction with the Canadian Border Services Agency (CBSA) to help border security agents determine whether travelers coming into Canada may have undisclosed motives for entering the country.

“AVATAR is a kiosk, much like an airport check-in or grocery store self-checkout kiosk,” said San Diego State University management information systems professor Aaron Elkins. “However, this kiosk has a face on the screen that asks questions of travelers and can detect changes in physiology and behavior during the interview. The system can detect changes in the eyes, voice, gestures and posture to determine potential risk. It can even tell when you’re curling your toes.”

The video of an accident on the Autobahn in the Netherlands caught on the dashcam of a Tesla Model X shows the Autopilot’s forward collision warning predicting an accident before it could be detected by the driver.

With the release of Tesla’s version 8.0 software update in September, the automaker announced a new radar processing technology that was directly pushed over-the-air to all its vehicles equipped with the first generation Autopilot hardware.

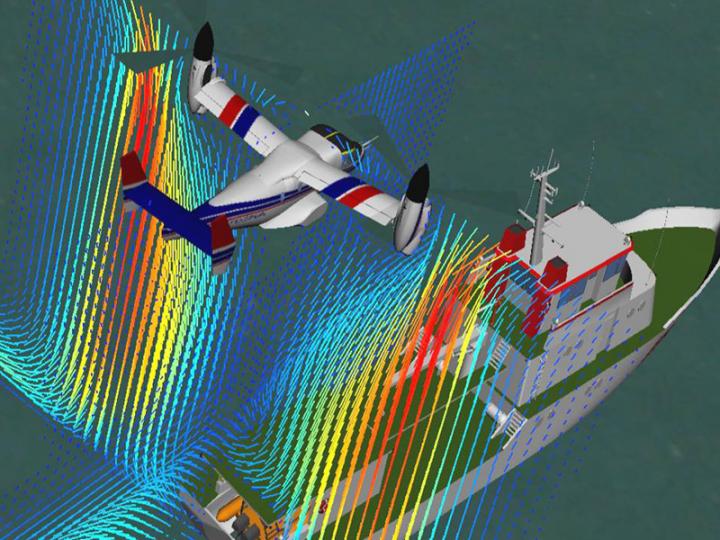

Missions at sea, in mountainous regions or close to skyscrapers are extremely risky for helicopter pilots. The turbulent air flows near oil rigs, ships, cliffs and tall buildings can throw a helicopter off balance and cause a crash. To provide pilots with optimal preparation for these challenging conditions, engineers at the Technical University of Munich (TUM) are developing new simulation software.

Providing helicopter pilots with the best possible preparation for extreme situations: That is the goal of the new simulation software being developed by researchers working at TUM’s Chair of Helicopter Technology. For the first time, real-time computational analysis will be implemented for both fluid mechanics and flight dynamics. “Until now, flight simulators have not adequately reflected the reality of flying in close proximity to large objects,” says Dr. Juergen Rauleder. “The problem is that, when it comes to wind conditions and the response of the helicopter, existing programs follow a rigid pattern. That means that local variations and changing conditions are not taken into account — unless the entire flow environment is known in advance.”

But it is the unforeseen air flows that can be the most treacherous: For example, a moving ship causes air turbulence and sudden local shifts in wind speed known by specialists as “ship airwake flow”. It changes continually through wave action and fluctuating inflow conditions. In addition, turbulence occurs near the deck, the bridge and other ship structures. As a helicopter approaches the ship, there is interference between these air currents and the flow produced by the rotors. Conditions near a mountain slope or next to high buildings are similarly complicated. In all of these cases, the helicopter’s flight characteristics are influenced by complex and overlapping aerodynamic effects.