Baykar is moving forward in Kızılelma Unmanned Combat Aerial Vehicle (UCAV) programme. The first prototype of the aircraft has completed the second flight from facilities based at Çorlu Atatürk Airport without issue.

Year 2019 face_with_colon_three

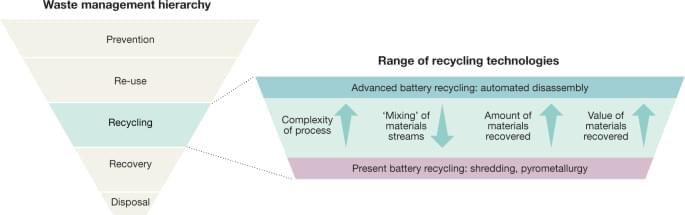

For high-cobalt cathodes such as lithium cobalt oxide (LCO) conventional pyrometallurgical (see section ‘Pyrometallurgical recovery’) or hydrometallurgical (see section ‘Hydrometallurgical recovery’) recycling processes can recover around 70% of the cathode value11. However, for other cathode chemistries that are not as cobalt-rich, this figure drops notably11. A 2019 648-lb Nissan Leaf battery, for example, costs US$6,500–8,500 new, but the value of the pure metals in the cathode material is less than US$400 and the cost of the equivalent amount of NMC (an alternative cathode material) is in the region of US$4,000. It is important, therefore, to appreciate that cathode material must be directly recycled (or upcycled) to recover sufficient value. As direct recycling avoids lengthy and expensive purification steps, it could be particularly advantageous for lower-value cathodes such as LiMn2O4 and LiFePO4, where manufacturing of the cathode oxides is the major contributor to cathode costs, embedded energy and carbon dioxide footprint95.

Direct recycling also has the advantage that, in principle, all battery components20 can be recovered and re-used after further processing (with the exclusion of separators). Although there is substantial literature regarding the recycling of the cathode component from spent LIBs, research on recycling of the graphitic anode is limited, owing to its lower recovery value. Nevertheless, the successful re-use of mechanically separated graphite anodes from spent batteries has been demonstrated, with similar properties to that of pristine graphite96.

Despite the potential advantages of direct recycling, however, considerable obstacles remain to be overcome before it can become a practical reality. The efficiency of direct recycling processes is correlated with the state of health of the battery and may not be advantageous where the state of charge is low97. There are also potential issues with the flexibility of these routes to handle metal oxides of different compositions. For maximum efficiency, direct recycling processes must be tailored to specific cathode formulations, necessitating different processes for different cathode materials97. The ten or so years spent in a vehicle—followed, perhaps, by a few more in a second-use application—therefore present a challenge in an industry where battery formulations are evolving at a rapid pace. Direct recycling may struggle to accommodate feedstocks of unknown or poorly characterized provenance, and there will be commercial reluctance to re-use material if product quality is affected.

According to Chinese media sources, the world’s first urban hydrogen powered train has just rolled off the production line in Chengdu, Sichuan Province.

According to Chinese media, the world’s first urban train powered by hydrogen has been produced via a joint venture between the CRRC Changchun Railway Company and Chengdu Rail Transit. While other hydrogen-powered trains exist, this is the first specifically developed for an urban environment.

The train rolled off the assembly line in Chengdu, Sichuan Province, in southwest China on Wednesday, the 18th of January, 2023, according to the same media reports.

Does Tesla know how to make cars for profit? You bet.

Sandy and Cory discuss Tesla’s price cuts.

ENHANCE YOUR TESLA WITH S3XY BUTTONS

https://enhauto.com/

We are selling stickers yet again! This time, we’re raising money to buy a Tesla Semi to tear down. You can get your own Uncle Sandy sticker for $15 — or $50 if you want yours signed by the Teardown Titan himself!

Link to purchase: https://munrolive.com/store/ols/products/uncle-sandy-sticker.

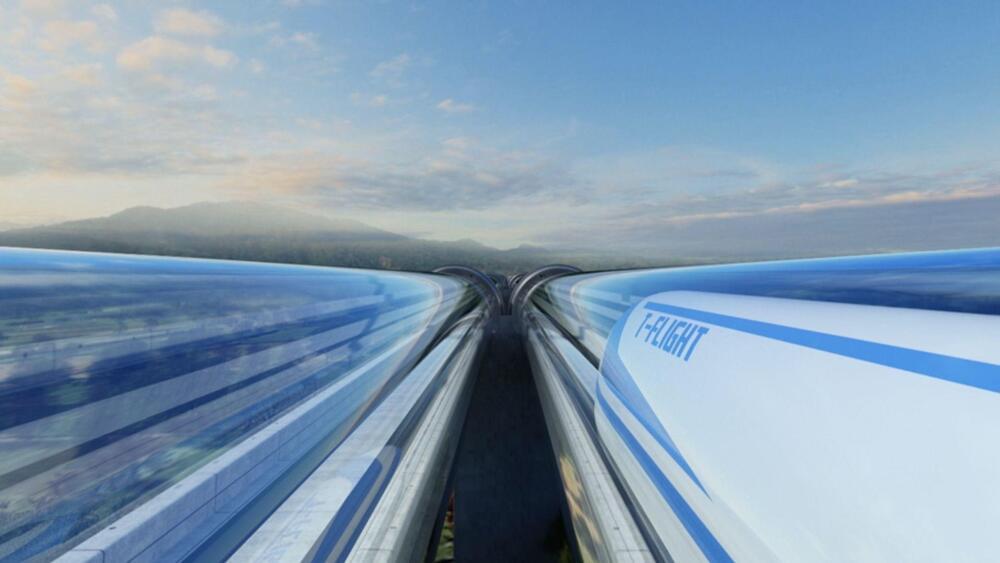

The train will be the world’s fastest ground-based transport technology if the project goes as planned.

An ultra-fast hyperloop train in China has completed its first test runs, according to a report by the South China Morning Post.

The world’s fastest ground-based transport technology.

Zhejiang Geely Holding Group.

These consisted of three test runs at a superconducting maglev test line in Datong, Shanxi province. The goal of the train is to eventually carry passengers and cargo at a speed of 621 miles/h (1,000 km per hour) or faster in a near-vacuum tube.

Claiming a system-level energy density 5X higher than batteries, Amogy has rolled out “the world’s first ammonia-powered, zero-emission semi truck.” It holds about 900 kWh of energy, like the Tesla Semi, but you can refuel it in about eight minutes.

The Ford Mustang Mach-E is being transformed into an electric hearse courtesy of Coleman Milne, giving you a silent way to go to the great beyond. But not wanting to leave out the living, the specialty vehicle manufacturer has also revealed plans for a Mustang Mach-E limousine.

This is not the first time Coleman Milne has dabbled in electric hearses, previously turning a Tesla Model S into a chariot of the dearly departed called the Whisper hearse, but the company claims it will be doing more of this sort of thing heading into 2023, with the Mach-E also forming the foundation of an electric limousine — another concept we’re no strangers to but will have to get used to in coming years.