Nice write up. What is interesting is that most folks still have not fully understood the magnitude of quantum and how as well as why we will see it as the fundamental ingredient to all things and will be key in our efforts around singularity.

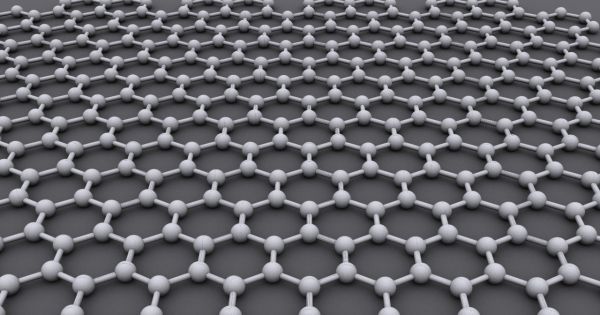

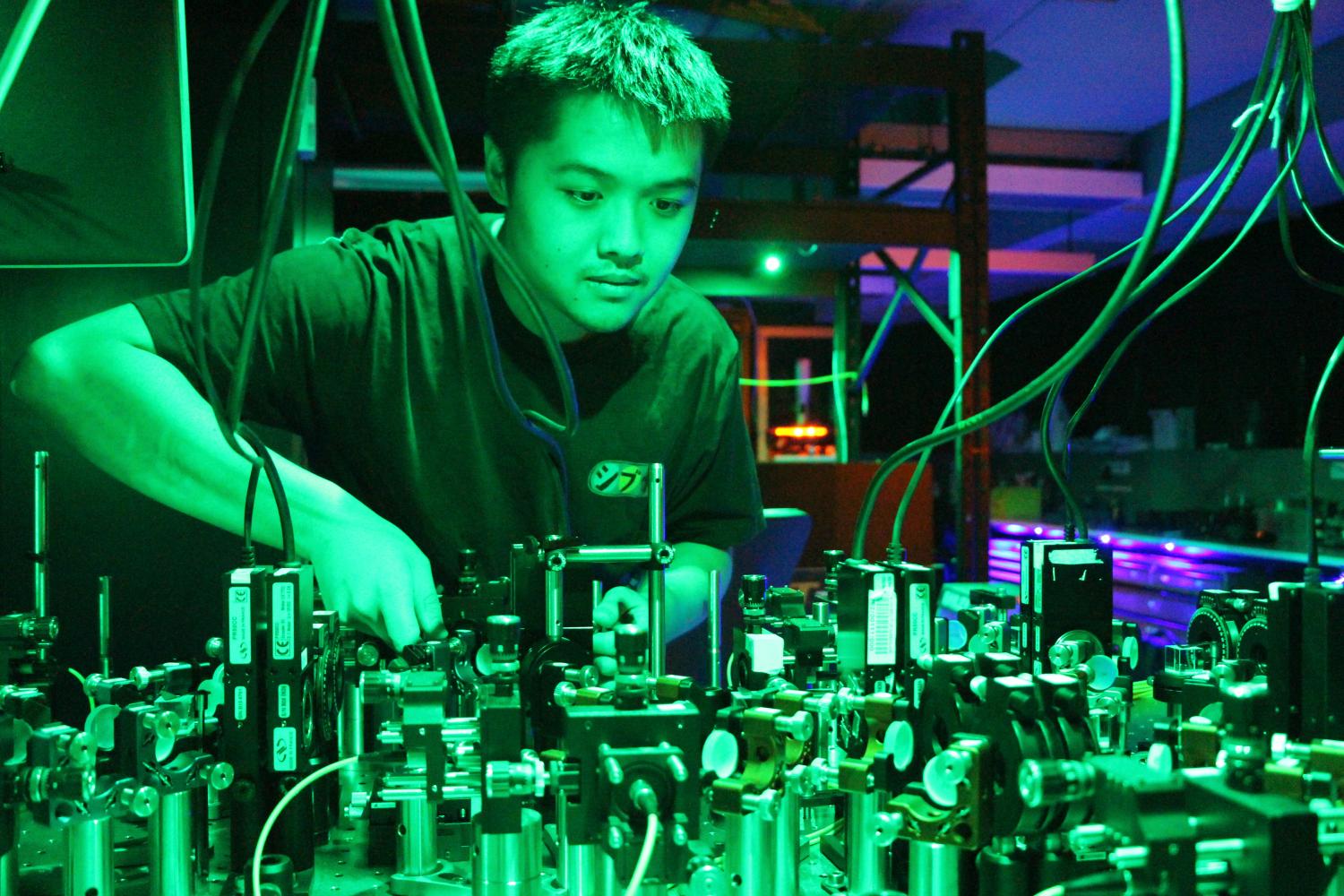

When it comes to studying transportation systems, stock markets and the weather, quantum mechanics is probably the last thing to come to mind. However, scientists at Australia’s Griffith University and Singapore’s Nanyang Technological University have just performed a ‘proof of principle’ experiment showing that when it comes to simulating such complex processes in the macroscopic world quantum mechanics can provide an unexpected advantage.

Griffith’s Professor Geoff Pryde, who led the project, says that such processes could be simulated using a “quantum hard drive”, much smaller than the memory required for conventional simulations.

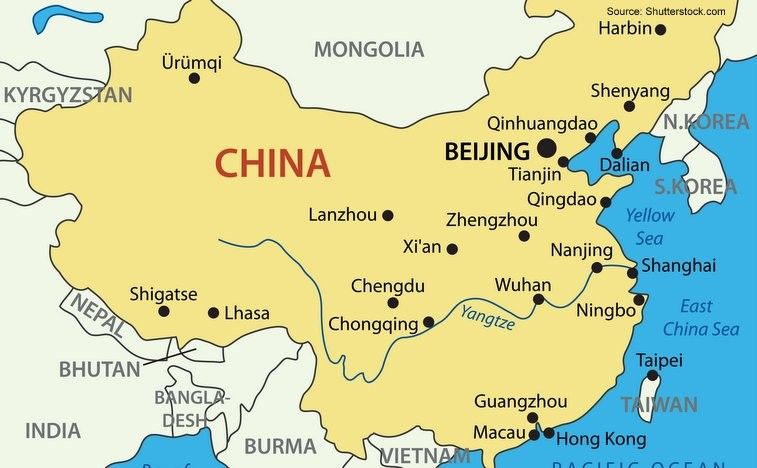

“Stephen Hawking once stated that the 21st century is the ‘century of complexity’, as many of today’s most pressing problems, such as understanding climate change or designing transportation system, involve huge networks of interacting components,” he says.