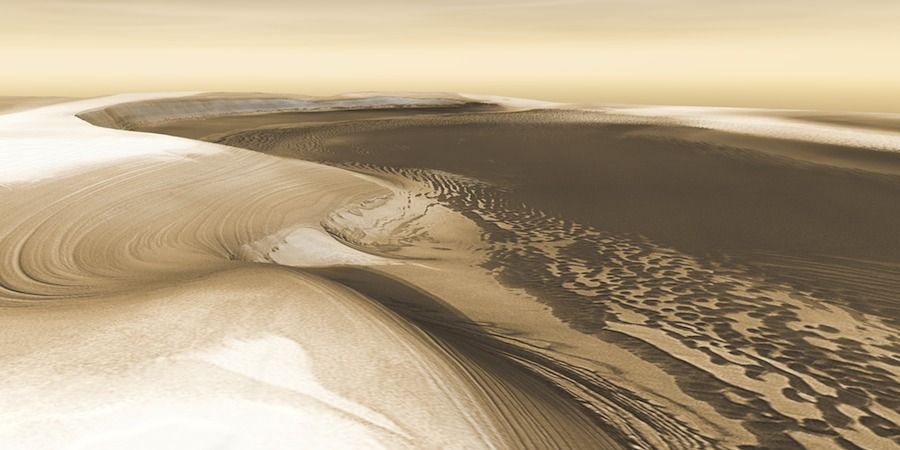

NASA is investigating the potential for a tiny wind turbine to power instruments during long Martian polar night.

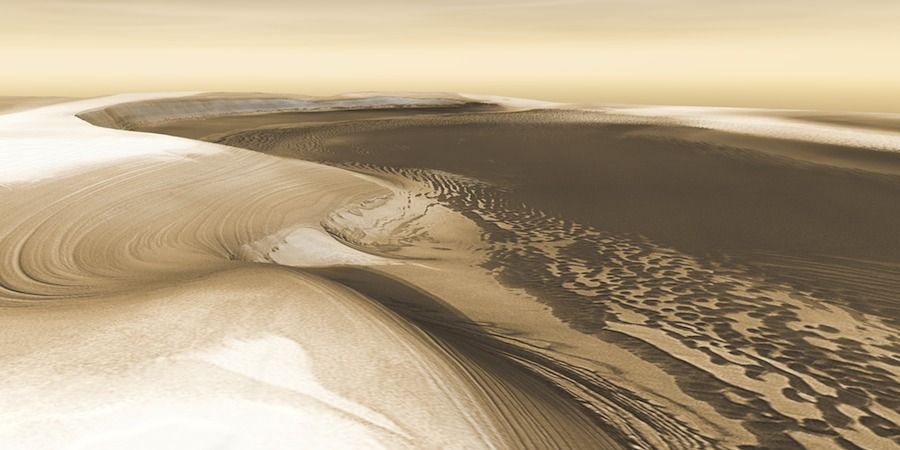

Reaction Engines and Britain’s Science and Technology Facilities Council (STFC) have completed a concept study into the practicality of using ammonia as a jet aviation fuel. By teaming Reaction Engines’s heat exchanger technology with STFC’s advanced catalysts, they hope to produce a sustainable, low-emission propulsion system for tomorrow’s aircraft.

Modern jet engines use a variety of fuels based on kerosene that have a very high energy density that can propel aircraft well beyond the speed of sound and carry passengers and cargoes across the globe. Unfortunately, such fuels are also derived from fossil fuels and produce significant carbon dioxide emissions, which the airline industry and many governments have pledged to reduce radically by 2050.

One way of achieving these cuts is to look at alternatives to conventional jet fuels to power airliners. The problem is that most of these alternatives have much lower energy densities than standard aviation fuels and suffer from other drawbacks. For example, present-day battery technology would require future aircraft to be very small, short-range, and with little payload capacity. Meanwhile, liquid hydrogen could be a viable alternative, but so much of it would need to be carried that planes would have to be completely redesigned and new infrastructure built.

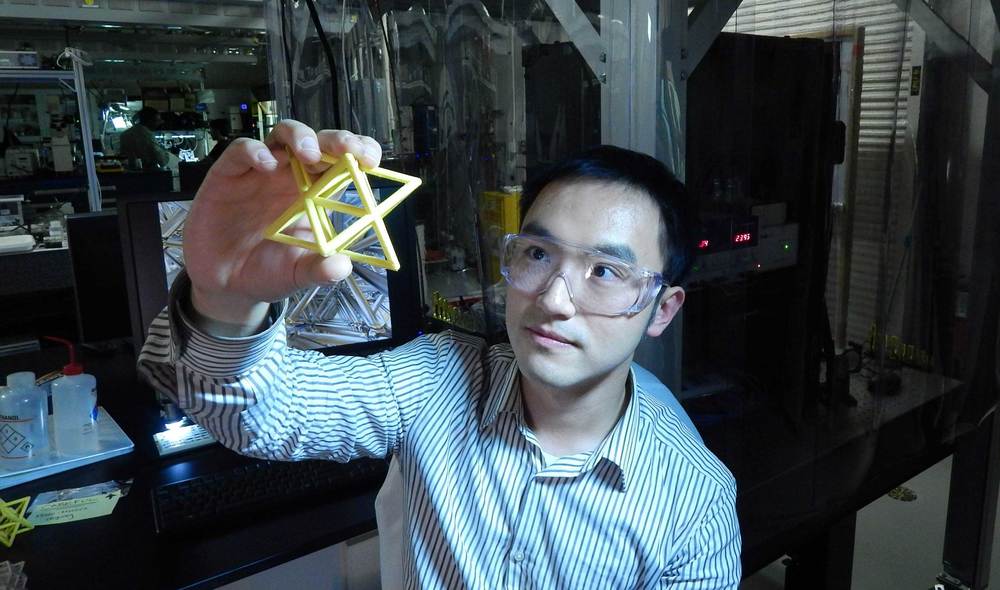

Plants have a seemingly effortless skill – turning sunlight into energy – and scientists have been working to artificially emulate this photosynthesis process. The ultimate benefits for renewable energy could be huge – and a new approach based on ‘photosheets’ could be the most promising attempt we’ve seen so far.

The new device takes CO2, water, and sunlight as its ingredients, and then produces oxygen and formic acid that can be stored as fuel. The acid can either be used directly or converted into hydrogen – another potentially clean energy fuel.

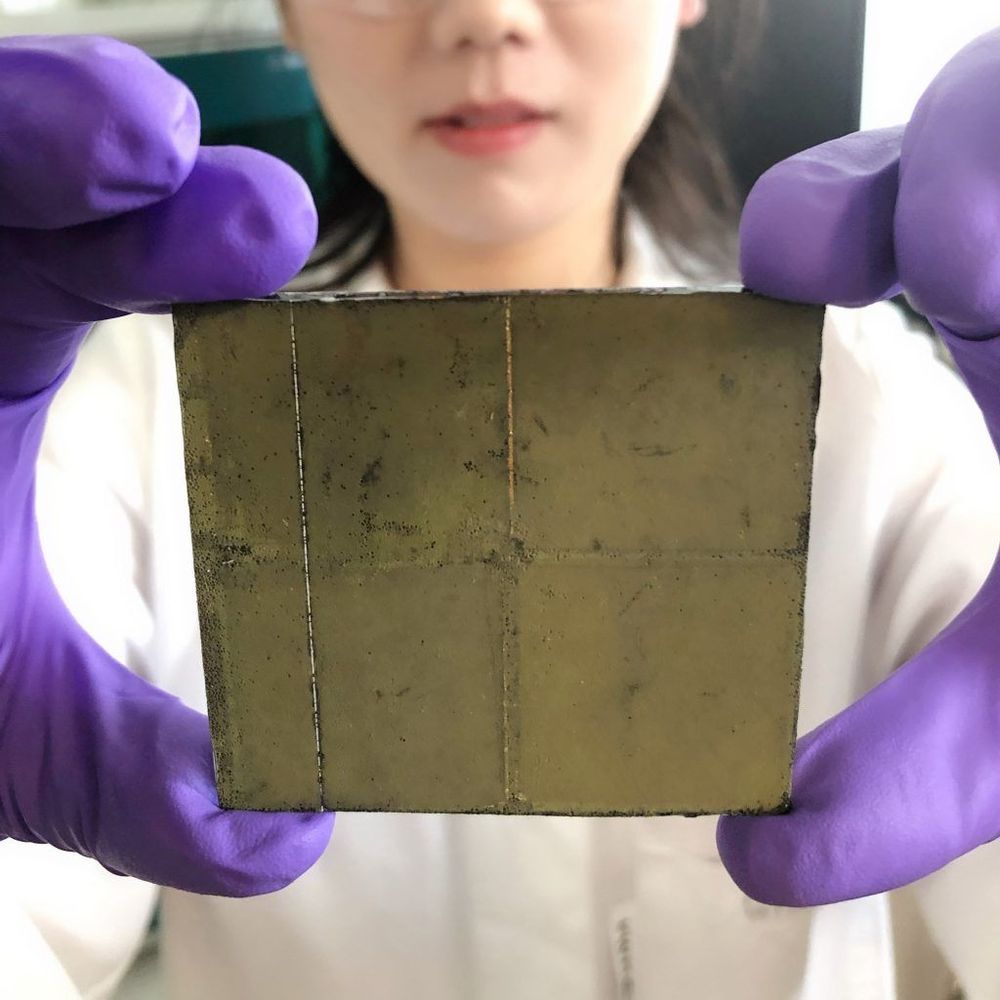

Key to the innovation is the photosheet — or photocatalyst sheet — which uses special semiconductor powders that enable electron interactions and oxidation to occur when sunlight hits the sheet in water, with the help of a cobalt-based catalyst.

TerraVis™ system — a platform for versatile and cost-effective solar power integrations for pick-up trucks. This groundbreaking innovation is the very first to combine practical, durable tonneau covers with a cutting-edge solar generation and energy storage system. This website launch marks the first release of design and application-related details.

Terravis | the future by worksport | welcome: terravis.

Circa 2017

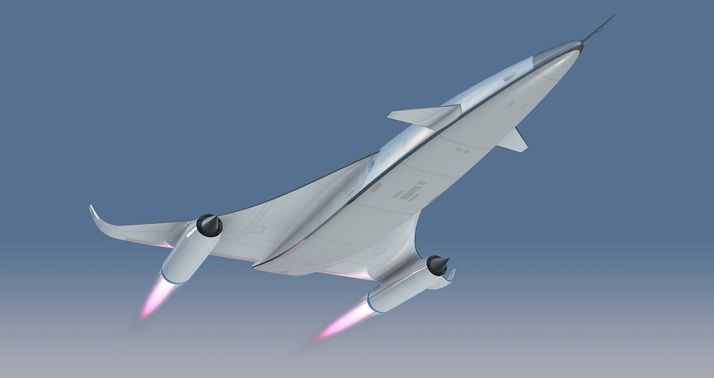

Imagine materials strong enough to use in building airplanes or motor cars, yet are literally lighter than air. Soon, that may not be so hard to do because a team of researchers from MIT and Lawrence Livermore National Laboratory (LLNL) have developed new ultra-lightweight materials that are as light as aerogel, but 10,000 times stiffer, and may one day revolutionize aerospace and automotive designs.

Aerogels are incredibly light, so light that the record holder, aerographene, boasts a density of just 0.16 mg/cm3. Currently, aerogels are used for insulation, tennis racquets, as a means of controlling oil spills, and were used on the NASA Stardust mission to collect samples from a comet’s tail. Unfortunately, despite its seemingly ephemeral nature, its very much a solid and will shatter if pressed hard enough, so its use is limited.

The new materials developed by the MIT/LLNL team aren’t aerogels, but are metamaterials. That is, artificial materials with properties that aren’t found in nature. The idea is to structure it, so that it has the lightness of aerogel, but is much stronger. The strength of the new materials comes from their geometric structure, not their chemical composition.

In a step closer to skyscrapers that serve as power sources, a team led by University of Michigan researchers has set a new efficiency record for color-neutral, transparent solar cells.

The team achieved 8.1% efficiency and 43.3% transparency with an organic, or carbon-based, design rather than conventional silicon. While the cells have a slight green tint, they are much more like the gray of sunglasses and automobile windows.

“Windows, which are on the face of every building, are an ideal location for organic solar cells because they offer something silicon can’t, which is a combination of very high efficiency and very high visible transparency,” said Stephen Forrest, the Peter A. Franken Distinguished University Professor of Engineering and Paul G. Goebel Professor of Engineering, who led the research.

The tech entrepreneur Elon Musk on Friday showed off a pig whose brain he says has been implanted with a small computer.

“We have a healthy and happy pig, initially shy but obviously high energy and, you know, kind of loving life, and she’s had the implant for two months,” Musk said of Gertrude, the pig.

The billionaire entrepreneur, whose other companies include Tesla and SpaceX, presented during a live-stream event to recruit employees for his neuroscience startup Neuralink. He described Gertrude’s coin-sized implant as “a Fitbit in your skull with tiny wires”.

The Boring Company’s Las Vegas tunnel will be operational in “only a few months,” according to company frontman Elon Musk, who updated the project’s progress on August 28.

Musk, CEO of the Boring Company, set out to create a new source of transportation in high-traffic areas several years ago while living in Los Angeles. While LA has a private test tunnel in Hawthorne, California, near the Tesla Design Studio and SpaceX Headquarters, Musk wanted to expand upon the idea and move it to other cities.

Las Vegas needed a transportation solution to handle traffic on the Strip, where many of the visitors spend the majority of their time while visiting the Sin City. However, the Las Vegas Convention Center also desired an underground people mover, and the Boring Co. was more than happy to make a $52.5 million bid on the project, which was accepted.

In October 2019, the Boring Company officially opened the construction of the Las Vegas Convention Center tunnel project. By January, the tunnel was nearly 50% complete.

The process of boring tunnels under the LVCC was completed in May, and now the final touches are being put into place before it can be ready to assist in moving thousands of people from location to location in Las Vegas.

The phrase “too much of a good thing” may sound like a contradiction, but it encapsulates one of the key hurdles preventing the expansion of renewable energy generation. Too much of a service or commodity makes it harder for companies to sell them, so they curtail production.

Usually that works out fine: The market reaches equilibrium and economists are happy. But external factors are bottlenecking renewable electricity despite the widespread desire to increase its capacity.

UC Santa Barbara’s Sangwon Suh is all too familiar with this issue. The professor of industrial ecology has focused on it and related challenges for at least the past two years at the Bren School of Environmental Science & Management. “Curtailment is the biggest problem of renewable energy we are facing,” said Suh, who noted it will only escalate as renewable energy capacity increases.

More advances on artificial photosynthesis.

Scientists at the UK’s University of Cambridge have developed a renewable energy device that mimics photosynthesis by making fuel from sunlight, carbon dioxide and water.

Taking inspiration from the way that plants create their own energy, the device is a slim sheet that produces oxygen and formic acid from water, carbon dioxide and sunlight.

Formic acid can be stored and used as fuel on its own, or turned into hydrogen fuel.