Tiny carbon tubes beam out stronger light by stealing a boost from internal vibrations—a discovery that could revolutionize solar power and advanced electronics.

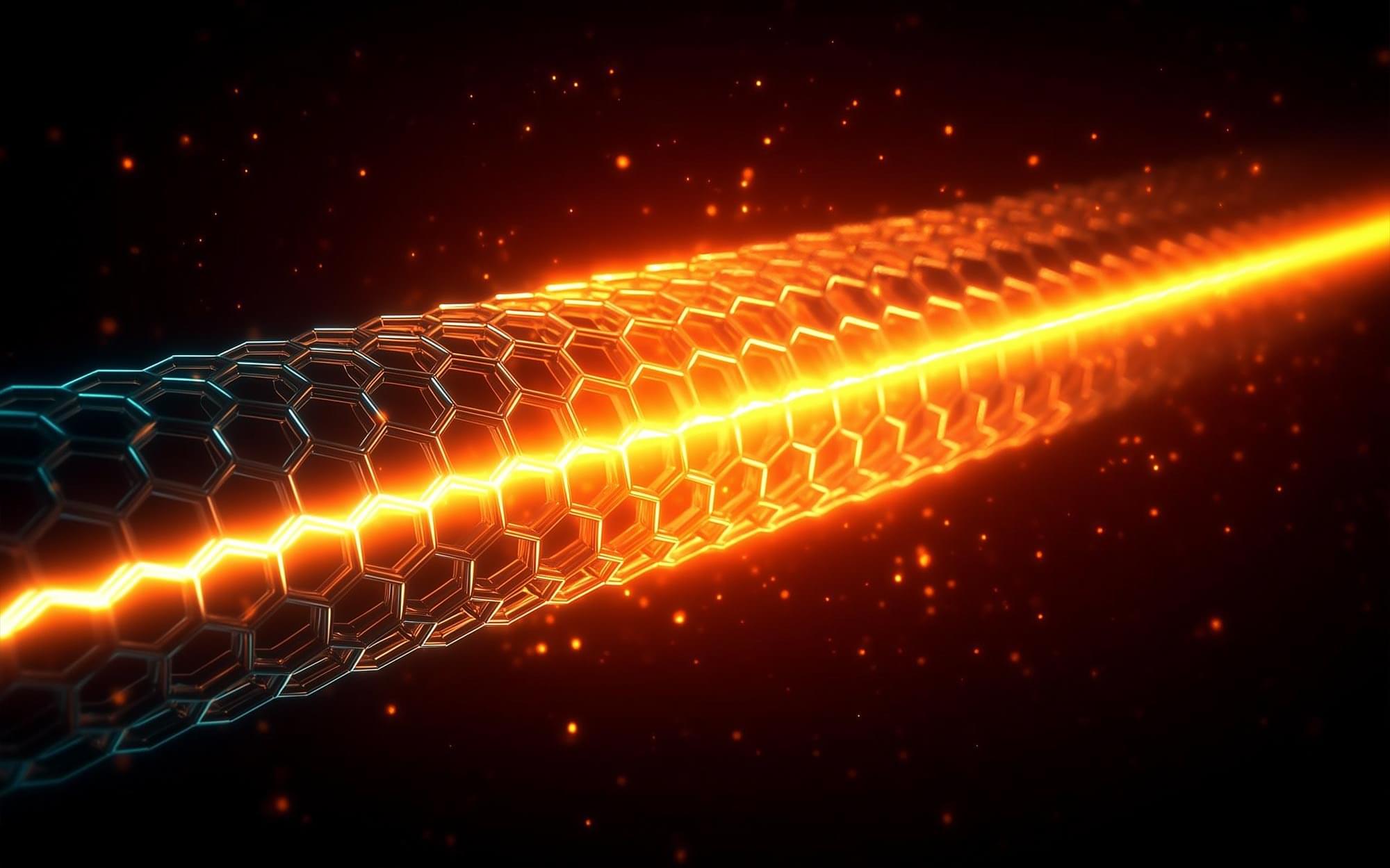

A new perovskite solar cell (PSC) demonstrates remarkable resilience even in high heat conditions, thanks to an innovative protective film. The research team suggests that these findings represent a significant step toward commercialization by addressing thermal stability issues.

A research team, led by Professor Dong Suk Kim at the UNIST Graduate School of Carbon Neutrality, in collaboration with Professor Tae Kyung Lee from Gyeongsang National University (GNU), has successfully engineered a heat-resistant PSC capable of withstanding high-temperature encapsulation processes.

This innovative solar cell demonstrated a remarkable initial efficiency of 25.56% and maintained over 85% of its initial efficiency after operating under conditions of 85°C and 85% relative humidity for up to 1,000 hours. The findings are published in the journal Energy & Environmental Science.

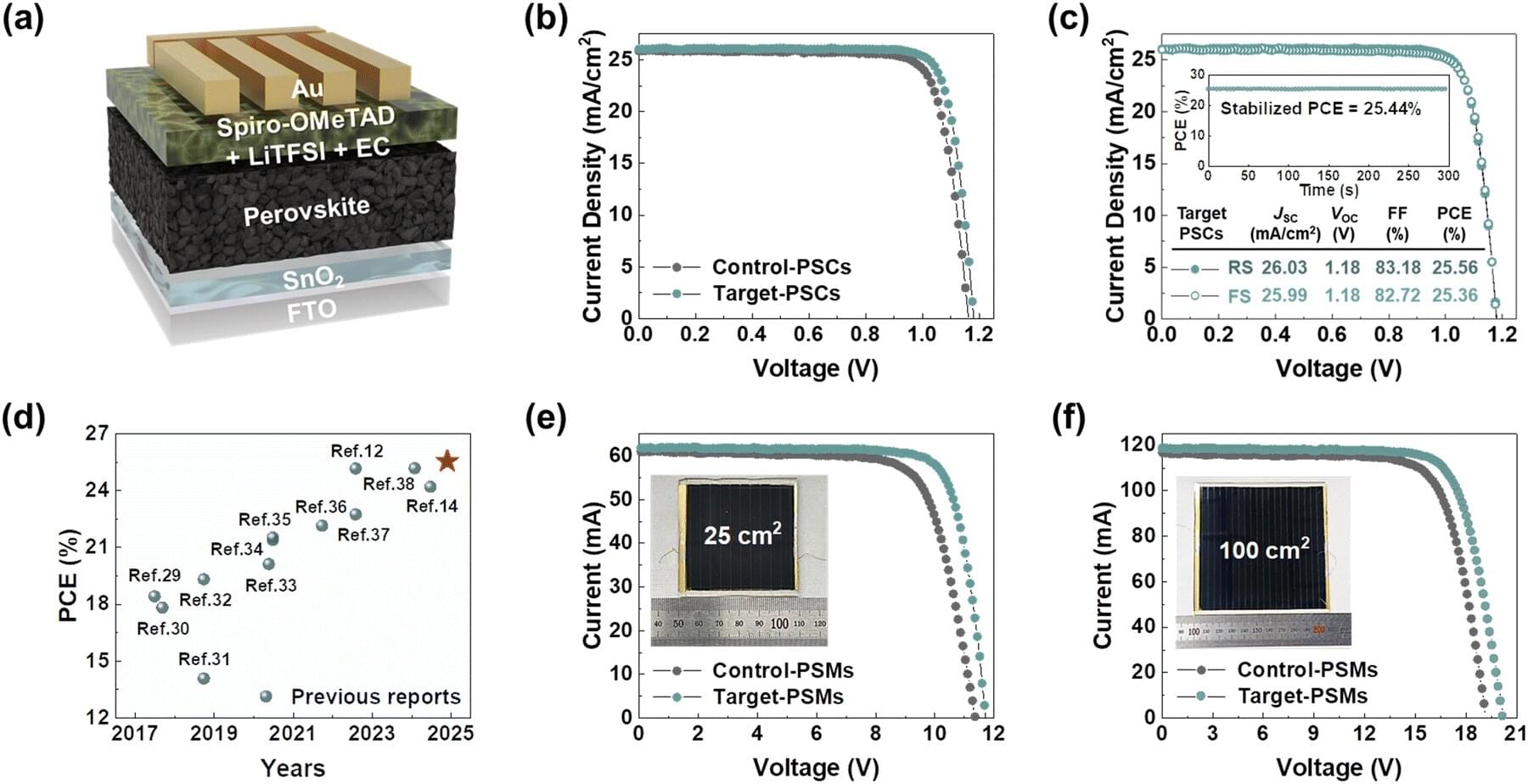

When Hunga Tonga–Hunga Haʻapai, an underwater volcano near Tonga in the South Pacific Ocean, erupted in 2022, scientists expected that it would spew enough water vapor into the stratosphere to push global temperatures past the 1.5 C threshold set by the Paris Accords. A new UCLA-led study shows that not only did the eruption not warm the planet, but it actually reduced temperatures over the Southern Hemisphere by 0.1 C.

The reason: The eruption formed smaller sulfate aerosols that had an efficient cooling effect that unexpectedly outweighed the warming effect of the water vapor. Meanwhile, the water vapor interacted with sulfur dioxide and other atmospheric components, including ozone, in ways that did not amplify warming.

While that’s good news, the study also suggests that efforts to reverse climate change by loading the atmosphere with substances that react with solar radiation to send heat back out into space, an effort known as geoengineering, are potentially even riskier than previously thought and must take new complications into account.

IN A NUTSHELL 🌿 The Dragonfly Turbine is designed by Renzo Piano and ENEL Green Power, inspired by the flight of dragonflies. 🏙️ It features a compact and eco-friendly design that blends seamlessly into urban landscapes, minimizing visual impact. 💡 The turbine maximizes wind capture efficiency even in low-wind conditions, providing reliable energy output. 🇮🇹

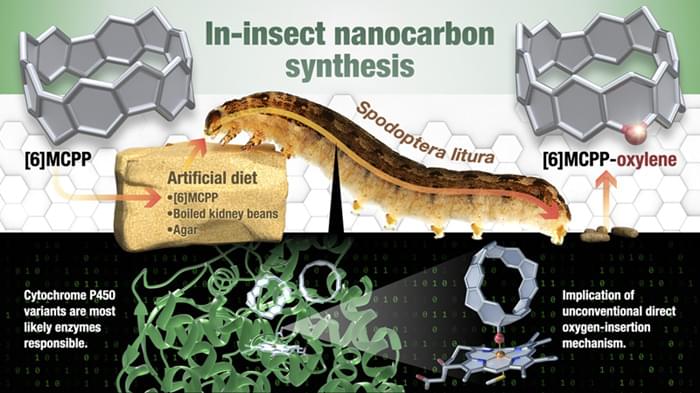

Researchers led by Kenichiro Itami at the RIKEN Pioneering Research Institute (PRI) / RIKEN Center for Sustainable Resource Science (CSRS) have successfully used insects as mini molecule-making factories, marking a breakthrough in chemical engineering. Referred to as “in-insect synthesis,” this technique offers a new way to create and modify complex molecules, which will generate new opportunities for the discovery, development, and application of non-natural molecules, such as nanocarbons.

Molecular nanocarbons are super tiny structures made entirely of carbon atoms. Despite their minuscule size, they can be mechanically strong, conduct electricity, and even emit fluorescent light. These properties make them ideal for use in applications like aerospace components, lightweight batteries, and advanced electronics. However, the precision required to manufacture these tiny structures remains a major obstacle to their widespread use. Conventional laboratory techniques struggle with the fine manipulation needed to put these complex molecules together atom by atom, and their defined shapes make it especially difficult to modify them without disrupting their integrity.

“Our team has been conducting research on molecular nanocarbons, but along with that, we’ve also developed molecules that act on mammals and plants,” says Itami. “Through those experiences, we suddenly wondered — what would happen if we fed nanocarbons to insects?”

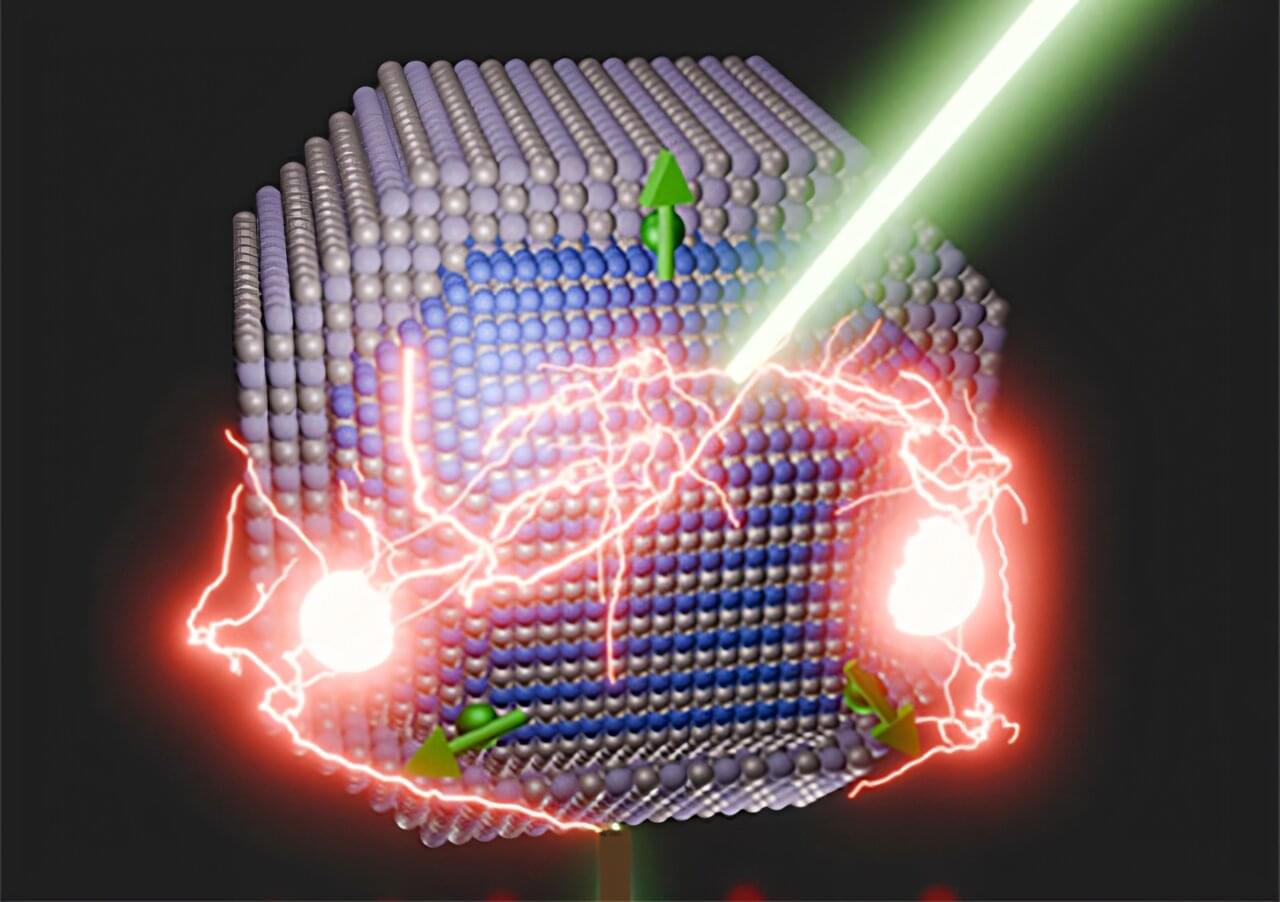

Quantum dots are microscopic semiconductor crystals developed in the lab that share many properties with atoms, including the ability to absorb or emit light, a technology that Los Alamos researchers have spent nearly three decades evolving. Through carrier multiplication, in which a single absorbed photon generates two electron-hole pairs, called excitons, quantum dots have the unique ability to convert photons more efficiently to energy.

“Our work demonstrates how purely quantum mechanical spin-exchange interactions can be harnessed to enhance the efficiency of photoconversion devices or photochemical reactions,” says Victor Klimov, the team’s principal investigator at the Lab. “This not only deepens our fundamental understanding of quantum mechanical phenomena but also introduces a new paradigm for designing advanced materials for energy applications.”

In this latest research, published in the journal Nature Communications, Los Alamos researchers improved this ability by introducing magnetic manganese impurities into quantum dots. This novel approach to highly efficient carrier multiplication leverages ultrafast spin-exchange interactions mediated by manganese ions to capture the energy of energetic (hot) carriers generated by incident photons and convert it into additional excitons.

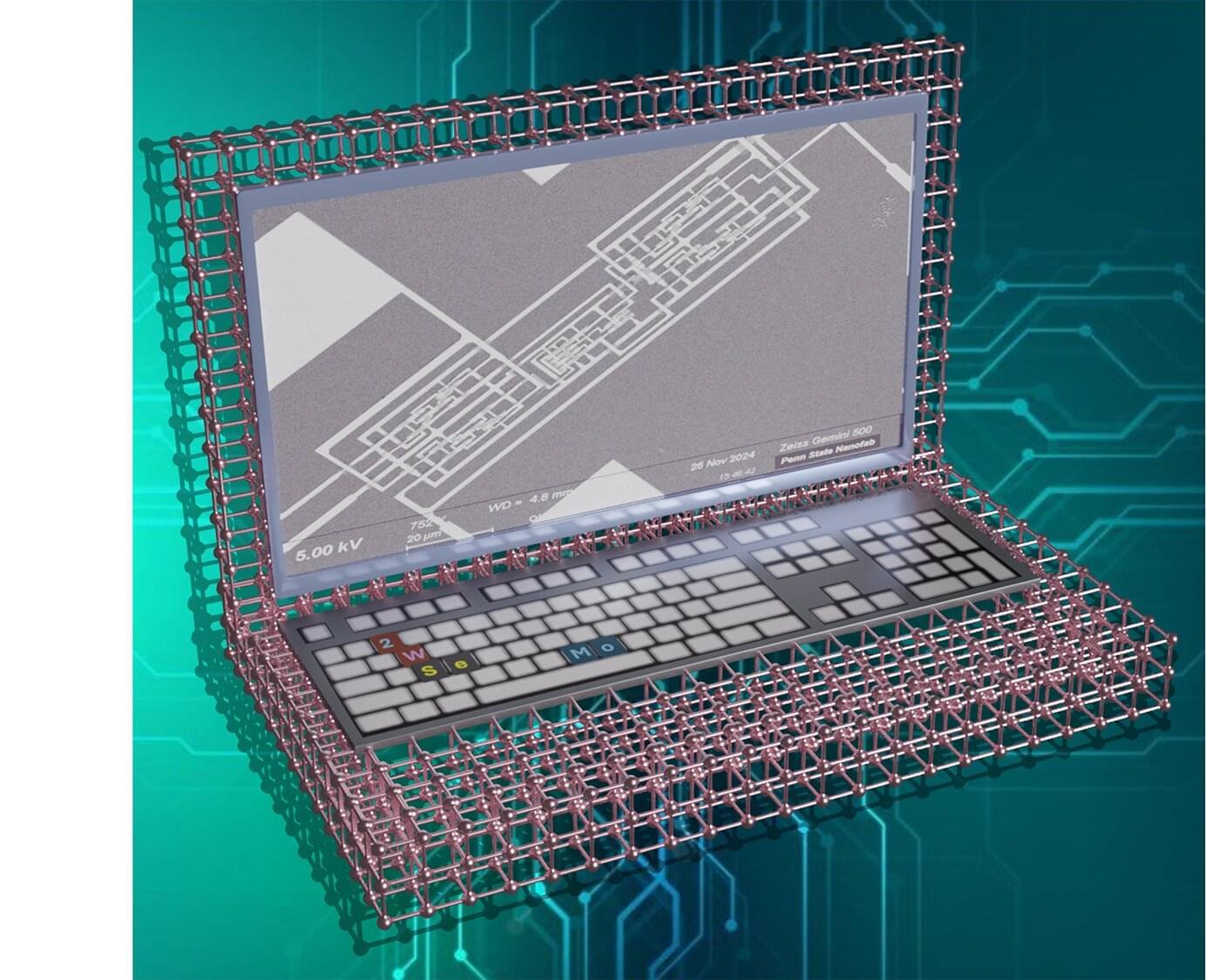

Silicon is king in the semiconductor technology that underpins smartphones, computers, electric vehicles and more, but its crown may be slipping, according to a team led by researchers at Penn State.

In a world first, they used two-dimensional (2D) materials, which are only an atom thick and retain their properties at that scale, unlike silicon, to develop a computer capable of simple operations.

The development, published in Nature, represents a major leap toward the realization of thinner, faster and more energy-efficient electronics, the researchers said.

Lithium-ion batteries power everything from electric cars to laptops to leaf blowers. Despite their widespread adoption, lithium-ion batteries carry limited amounts of energy, and rare overheating can lead to safety concerns. Consequently, for decades, researchers have sought a more reliable battery.

Solid-state batteries are less flammable and can hold more energy, but they often require intense pressure to function. This requirement has made them difficult to use in applications, but new research from Georgia Tech could change that.

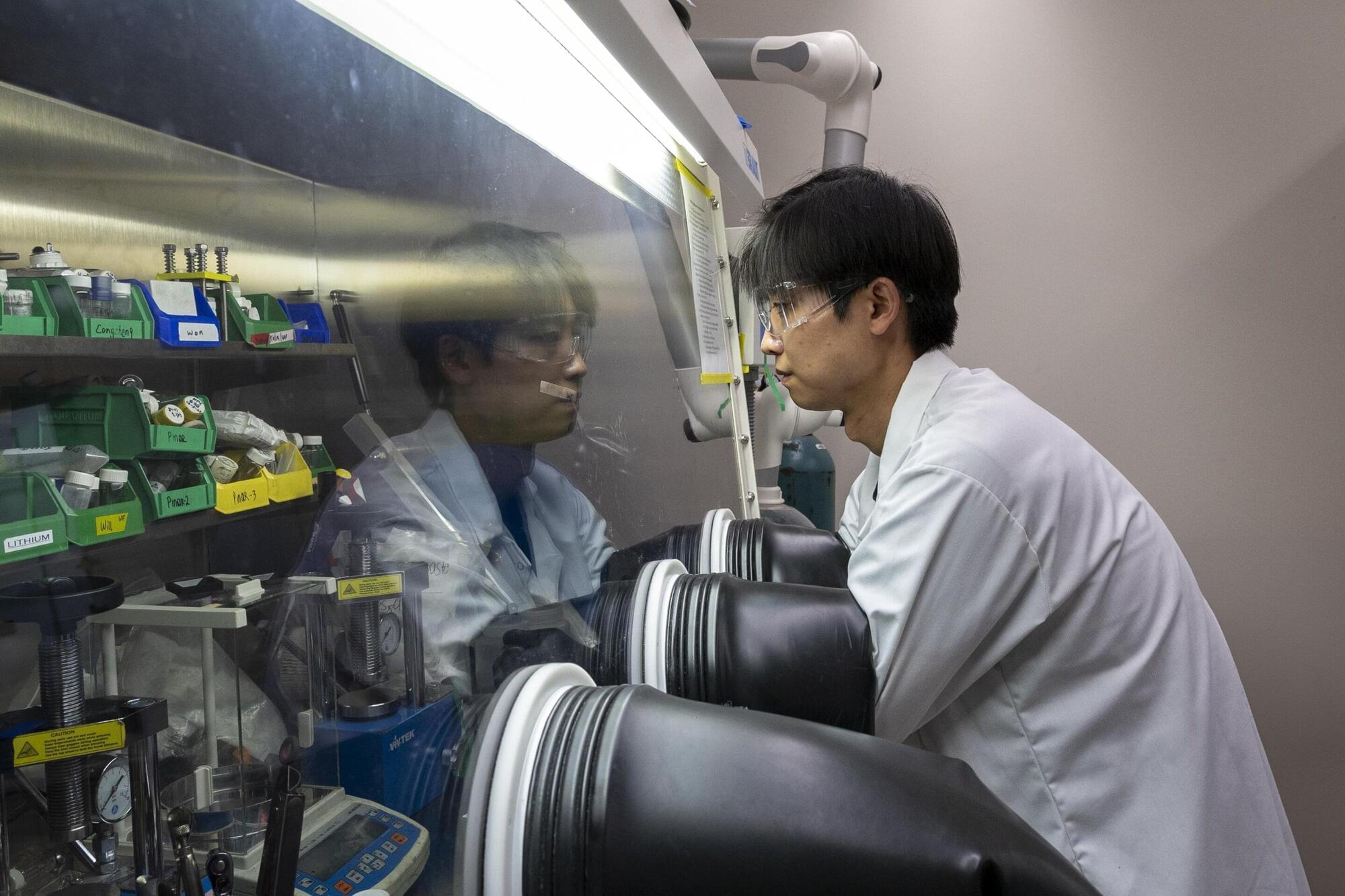

The research group of Matthew McDowell, professor and Carter N. Paden Jr. Distinguished Chair in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering, has designed a new metal for solid-state batteries that enables operation at lower pressures. While lithium metal is often used in these batteries, McDowell’s group discovered that combining lithium with softer sodium metal results in improved performance and novel behavior.

When the computer or phone you’re using right now blinks its last blink and you drop it off for recycling, do you know what happens?

At the recycling center, powerful magnets will pull out steel. Spinning drums will toss aluminum into bins. Copper wires will get neatly bundled up for resale. But as the conveyor belt keeps rolling, tiny specks of valuable, lesser-known materials such as gallium, indium and tantalum will be left behind.

Those tiny specks are critical materials. They’re essential for building new technology, and they’re in short supply in the U.S. They could be reused, but there’s a problem: Current recycling methods make recovering critical minerals from e-waste too costly or hazardous, so many recyclers simply skip them.