NASA and the U.S. Dept. of Energy have come together to solicit design proposals for a nuclear reactor that will power Lunar and Martian exploration!

Over the next fifteen years, multiple space agencies and their commercial partners intend to mount crewed missions to the Moon and Mars. In addition to placing “footprints and flags” on these celestial bodies, there are plans to establish the infrastructure to allow for a long-term human presence. To meet these mission requirements and ensure astronaut safety, several technologies are currently being researched and developed.

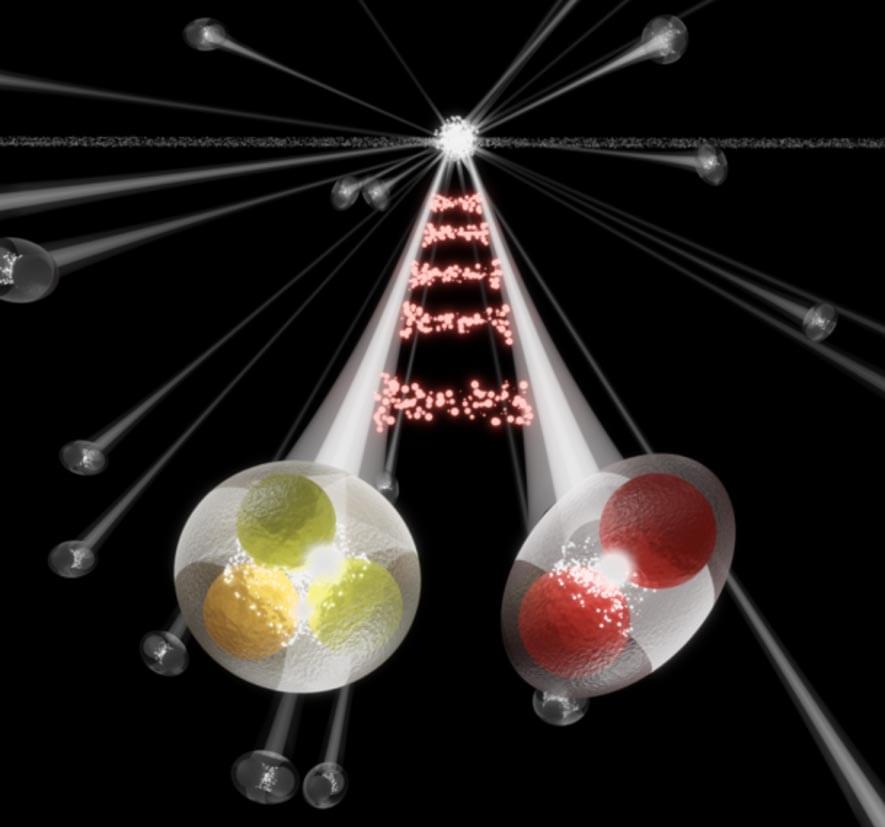

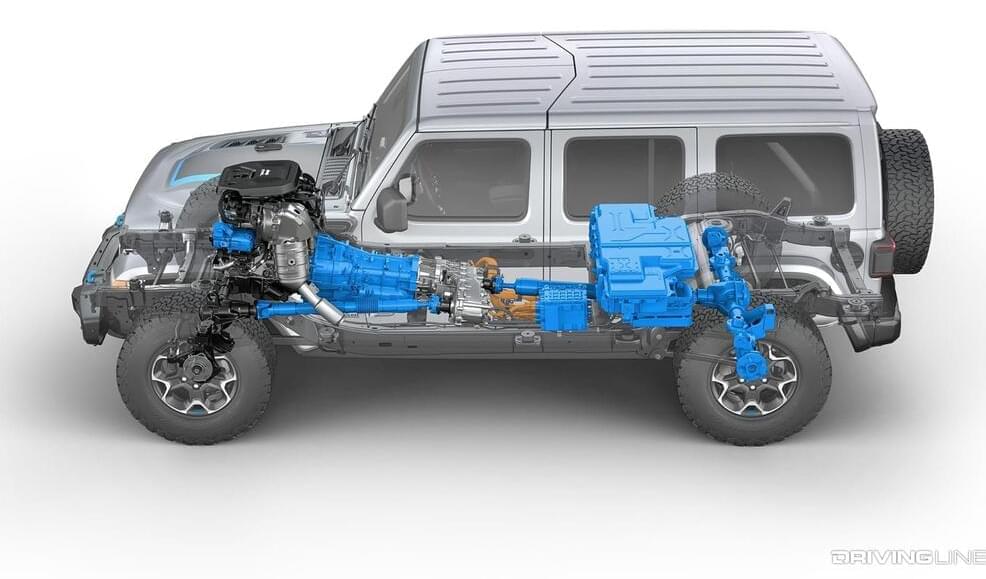

At their core, these technologies are all about achieving self-sufficiency in terms of resources, materials, and energy. To ensure that these missions have all the energy they need to conduct operations, NASA is developing a Fission Surface Power (FSP) system that will provide a safe, efficient, and reliable electricity supply. In conjunction with solar cells, batteries, and fuel cells, this technology will allow for long-term missions to the Moon and Mars in the near future.

For NASA, having fission reactors for lunar surface operations is a vital part of the Artemis Program, which aims to create a program of “sustained lunar exploration.” This means infrastructure is required, like the Lunar Gateway (where spacecraft will dock and resupply) and the Artemis Base Camp on the surface, where astronauts will eat, exercise, and sleep when not conducting extravehicular activities (EVAs) – i.e., surface operations.