BYD, the Chinese electric vehicle maker, is on the verge of surpassing Tesla as the global leader in EV sales.

China’s BYD is set to dethrone Tesla as the global EV sales leader, backed by affordable models and a robust charging infrastructure.

Tesla recorded $500M+ in gross profit from its Energy and Services (Supercharging) segments in Q3 2023. Elon Musk noted how strong energy gross margins were on the call, and insinuated strength in these businesses will continue. I think this is a super exciting development for Tesla investors as the company can smooth out cyclicality in it’s automotive business with consistent profits from its Energy and Services.

JAC Motors, a Volkswagen-backed Chinese automaker, is set to launch the first mass-produced electric vehicle (EV) with a sodium-ion battery through its new Yiwei brand. Although sodium-ion battery tech has a lower density (and is less mature) than lithium-ion, its lower costs, more abundant supplies and superior cold-weather performance could help accelerate mass EV adoption. CarNewsChina reports that the JAC Yiwei EV hatchback deliveries will begin in January.

Yiwei is a new brand in 2023 for JAC. Volkswagen has a 75 percent stake in (and management control of) JAC and owns 50 percent of JAC’s parent company, Anhui Jianghuai Automobile Group Holdings (JAG). The Chinese government owns the other half of JAG, making for one of the auto industry’s stranger pairings.

The Yiwei EV appears to be a rebranded version of the Sehol E10X hatchback (above), announced earlier this year. CarNewsChina describes the Sehol model as having a 252 km (157 miles) range with a 25 kWh capacity, 120 Wh / kg energy density, 3C to 4C charging, and a HiNa NaCR32140 cell. When JAC revealed the Yiwei brand in May, it said it would drop the Sehol label and rebrand all its vehicles to either JAC or Yiwei, leading us to this week’s EV reveal. JAC hasn’t yet said whether the Yiwei-branded model will keep the E10X moniker.

Tesla Giga Shanghai plans to release 2024 Model Y refresh as competition heats up in China.

People familiar with the matter told Bloomberg that Gigafactory Shanghai is already preparing to produce the 2024 refresh Model Y. Mass production on the new Model Y is expected to start by mid-2024.

The new Model Y units will be produced in the new phase of Gigafactory Shanghai. Production in the second phase of Tesla China’s factory will be suspended during New Year’s for upgrades. More updates to the Model Y assembly line will be made after the holidays.

A team of engineers, materials scientists and chemists at Nankai University, in China, has developed a microfiber-based meta-fabric that provides full-day thermoregulation of body temperature during periods of changing external temperatures.

In their paper published in the journal Science, the group describes how they developed their fabrics, how they work and how well they performed when tested. Xingyi Huang and Pengli, both with Shanghai Jiao Tong University, in China, have published a Perspective piece in the same journal issue outlining the work done by the team.

As the researchers note, clothing keeps people warm when it is cold, and in some cases, can help people stay cool in hot temperatures. Prior research efforts have attempted to extend the capabilities of clothing by adding heating or cooling elements, but thus far, most such products have proven to be too bulky for general use.

An innovative floating offshore wind turbine prototype was launched in New Bedford, Massachusetts this week. Instead of a single anchor tower, the approach uses a pyramid base that can also passively orient itself in the direction of the blowing wind.

As wind turbines get bigger and sweep larger areas in a single rotation, wind farms move offshore to gain maximum advantage from powerful sea winds. Over the years, the costs of wind-based energy have been plummeting, but as wind farms are set up farther into the sea, the costs and time required to set up new wind farms are bound to increase.

One of the early opportunities for Optimus to which Elon has alluded.

Disrupting prostitution, OnlyFans and the female profiteering off men’s emotional and sexual needs.

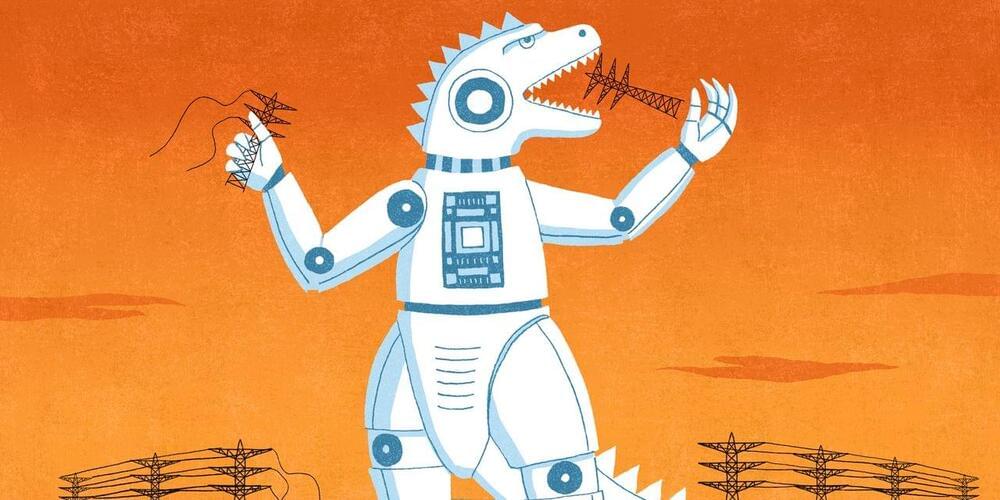

. Our guest, Mo Gawdat, former chief business officer for Google X, brings a stark warning from the forefront of technology. Having shaped the tech landscape through his work with IBM, Microsoft, and Google, Mo unflinchingly declares AI as a greater threat to humanity than global warming. The AI revolution is upon us, reshaping our future, irrespective of our stance. This episode delves into the startling implications of a world intertwined with sex robots. Could such artificial companionship eclipse our inherent need for human connection?