SpaceX released a new video recap of the flight of Starship SN10 that includes some never-before-seen perspectives from mid-flight.

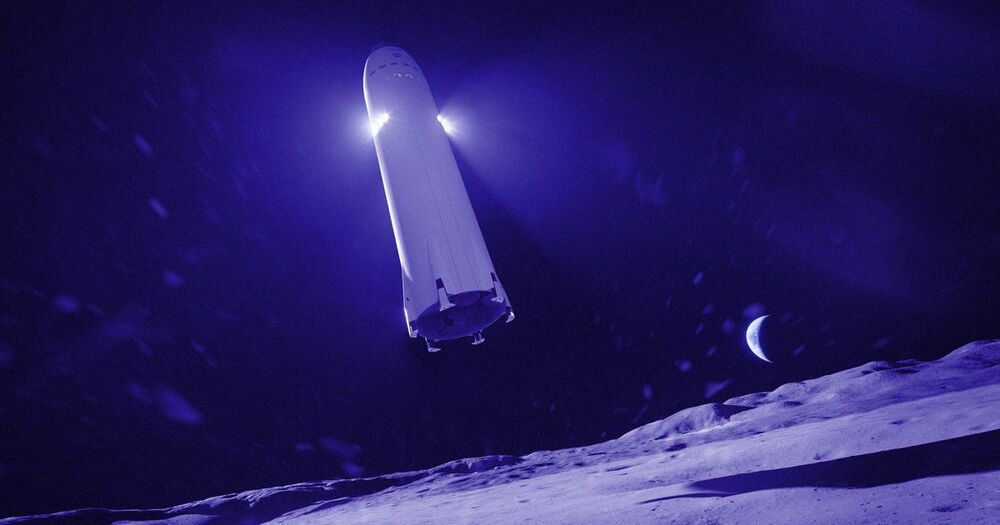

NASA officially announced that it’s going to announce who it will choose to build a rocket capable of bringing the first astronauts to the Moon’s surface since the Apollo missions.

But news of the decision may have just leaked to The Washington Post a little early.

According to documents obtained by the newspaper, NASA has officially chosen Elon Musk’s SpaceX to to build a lunar lander variant of its Starship spacecraft as part of the agency’s Artemis program — an extraordinary coup for the spacetech startup.

Four veteran astronauts will launch to the International Space Station on Thursday (April 22) for SpaceX’s Crew-2 mission, the second operational commercial crew flight of SpaceX’s Crew Dragon spacecraft.

The mission is set to blast off on April 22 from Pad 39A at NASA’s Kennedy Space Center in Florida at 6:11 a.m. EDT (1011 GMT). And, if all goes as planned, Crew Dragon will dock with the orbital outpost less than 24 hours later.

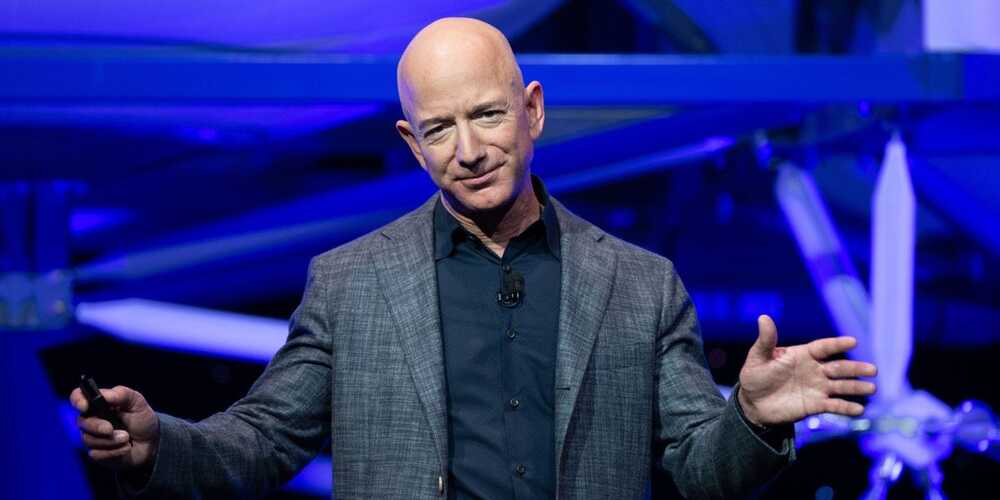

Blue Origin launched an uncrewed test flight of its New Shepard suborbital vehicle on April 14, 2021 from their West Texas facility. The capsule and rocket both landed several minutes after launch. The private spaceflight company complete an ‘astronaut rehearsal’ prior to the flight with future crew members boarding the capsule temporarily. Full Story: https://www.space.com/blue-origin-new-shepard-ns-15-launch-landing-success.

Credit: Blue Origin

Elon Musk’s SpaceX added more money to its February equity raise, with the amended total reaching nearly $1.2 billion.

Elon Musk’s SpaceX added more money to its most recent equity raise, according to a securities filing on Wednesday.

SpaceX held a second close of about $314 million, adding to the $850 million that CNBC reported the company raised in February. The amendment brings the round’s new total equity raised to $1.16 billion, which the company raised at a valuation of about $74 billion.

Strong demand for the company’s shares centers around its ambitious Starship and Starlink projects.

On April 13, 2021, Astrobotic announced that the Falcon Heavy rocket will launch the Griffin lander carrying NASA’s Volatiles Investigating Polar Exploration Rover (VIPER) to the moon.

Credit: Space.com | footage & animations: SpaceX & Astrobotic | produced & edited by Steve Spaleta (http://www.twitter.com/stevespaleta)

Circa 2013 o.o

We may still have a long way to go before we get a warp drive, but we may not have to wait much longer for our very own Star Trek-style phasers.

Scientists at NTT Basic Research Laboratories in Japan have managed to build the world’s first phaser, which is essentially a laser-like emission that works with sound instead of light. Like a laser, but not a laser. Aka a phonon laser. Basically: a phaser.

The technology essentially is able to emit a force via sound waves without the use of a laser, which is a major scientific feat. Scientists working on the project say the leap will make it “much easier to integrate into other applications and devices.”