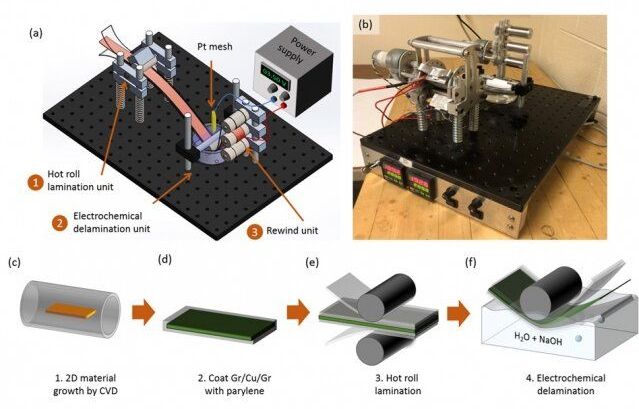

A new way of making large sheets of high-quality, atomically thin graphene could lead to ultra-lightweight, flexible solar cells, and to new classes of light-emitting devices and other thin-film electronics.

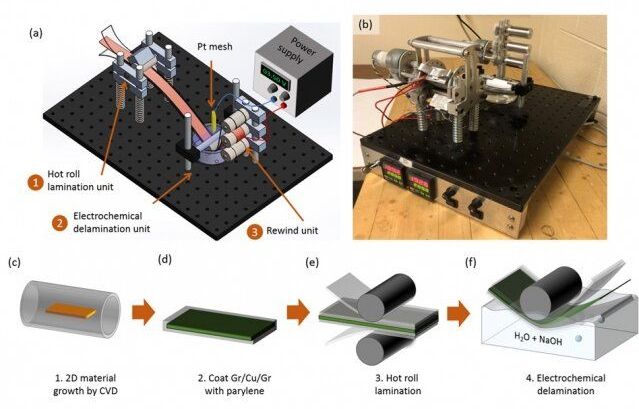

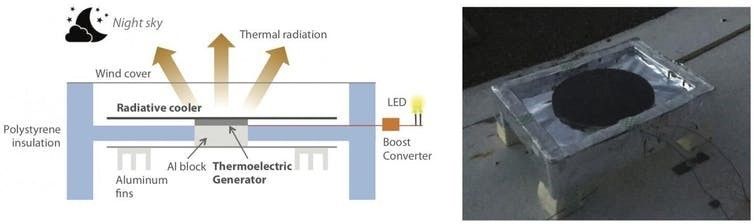

It sounds like something from a sci-fi movie, but the newly revealed Shadow-Effect Energy Generator (SEG) is a real prototype device. The fascinating concept could help us to transform the way renewable energy is generated indoors.

The SEG uses the contrast between darkness and light to produce electricity. It’s made up of a series of thin strips of gold film on a silicon wafer, placed on top of a flexible plastic base.

Whereas shadows are usually a problem for renewable solar energy production, here they’re actually harnessed to keep on generating power. The technology — which is cheaper to produce than a typical solar cell, according to its developers — produces small amounts of power and could be used in mobile gadgets, for example.

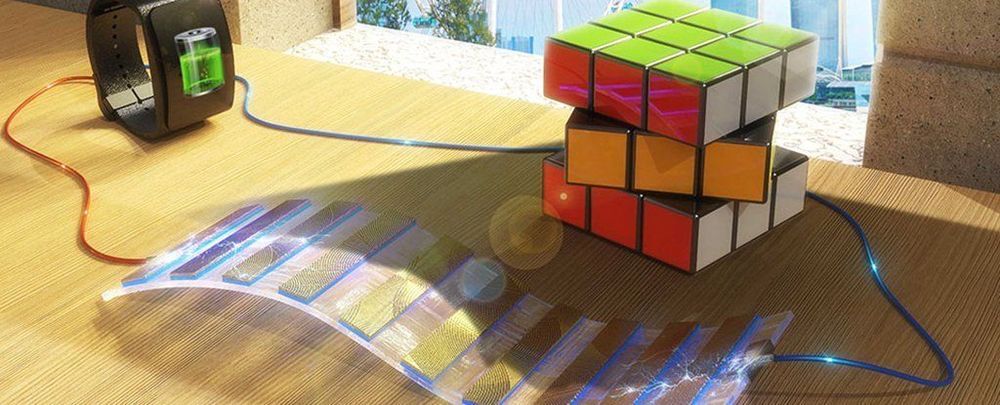

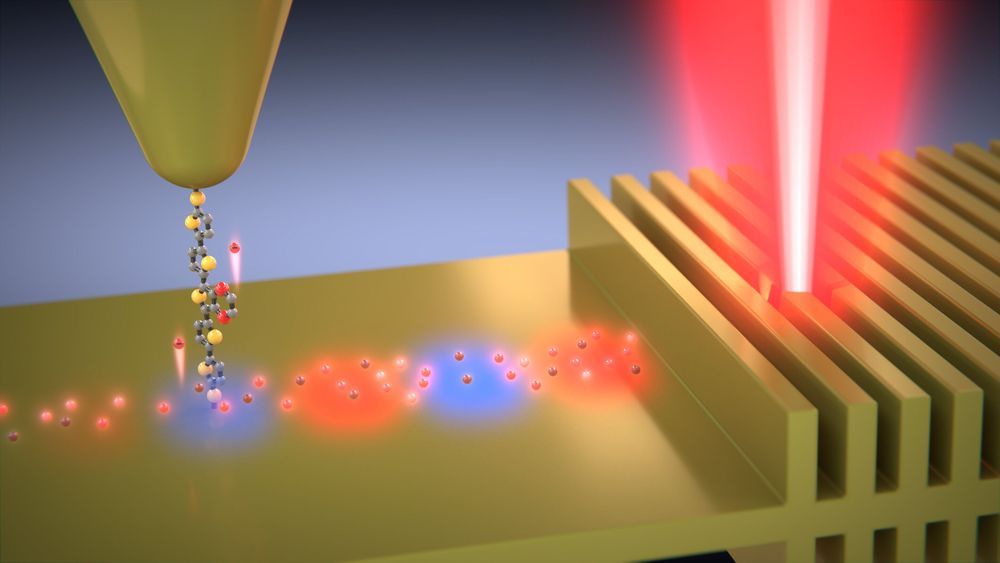

Highly energetic, “hot” electrons have the potential to help solar panels more efficiently harvest light energy.

But scientists haven’t been able to measure the energies of those electrons, limiting their use. Researchers at Purdue University and the University of Michigan built a way to analyze those energies.

“There have been many theoretical models of hot electrons but no direct experiments or measurements of what they look like,” said Vladimir “Vlad” Shalaev (shal-AYV), Purdue University’s Bob and Anne Burnett Distinguished Professor of Electrical and Computer Engineering, who led the Purdue team in this collaborative work.

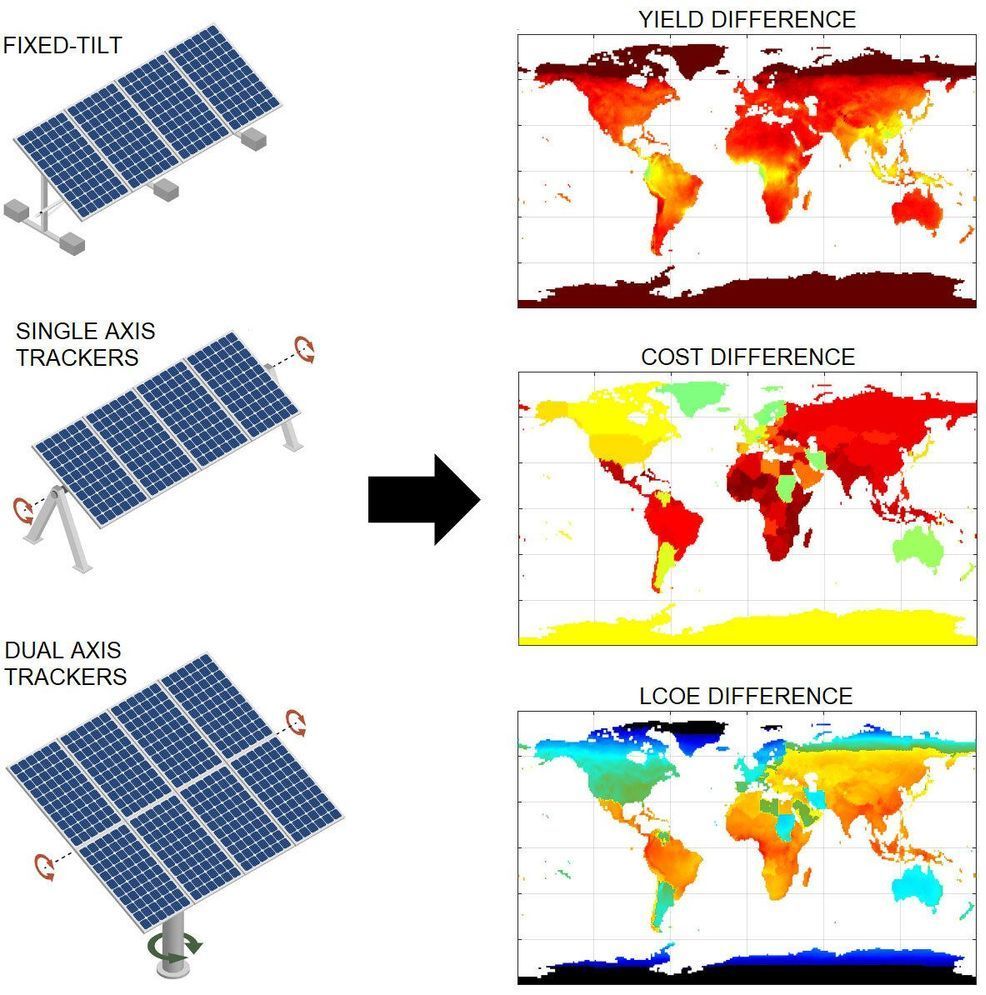

Solar power systems with double-sided (bifacial) solar panels—which collect sunlight from two sides instead of one—and single-axis tracking technology that tilts the panels so they can follow the sun are the most cost effective to date, researchers report June 3rd in the journal Joule. They determined that this combination of technologies produces almost 35% more energy, on average, than immobile single-panel photovoltaic systems, while reducing the cost of electricity by an average of 16%.

“The results are stable, even when accounting for changes in the weather conditions and in the costs from the solar panels and the other components of the photovoltaic system, over a fairly wide range,” says first author Carlos Rodríguez-Gallegos, a research fellow at the Solar Energy Research Institute of Singapore, sponsored by the National University of Singapore. “This means that investing in bifacial and tracking systems should be a safe bet for the foreseeable future.”

Research efforts tend to focus on further boosting energy output from solar power systems by improving solar cell efficiency, but the energy yield per panel can also be increased in other ways. Double-sided solar panels, for example, produce more energy per unit area than their standard counterparts and can function in similar locations, including rooftops. This style of solar panel, as well as tracking technology that allows each panel to capture more light by tilting in line with the sun throughout the day, could significantly improve the energy yield of solar cells even without further advancements in the capabilities of the cells themselves. However, the combined contributions of these recent technologies have not been fully explored.

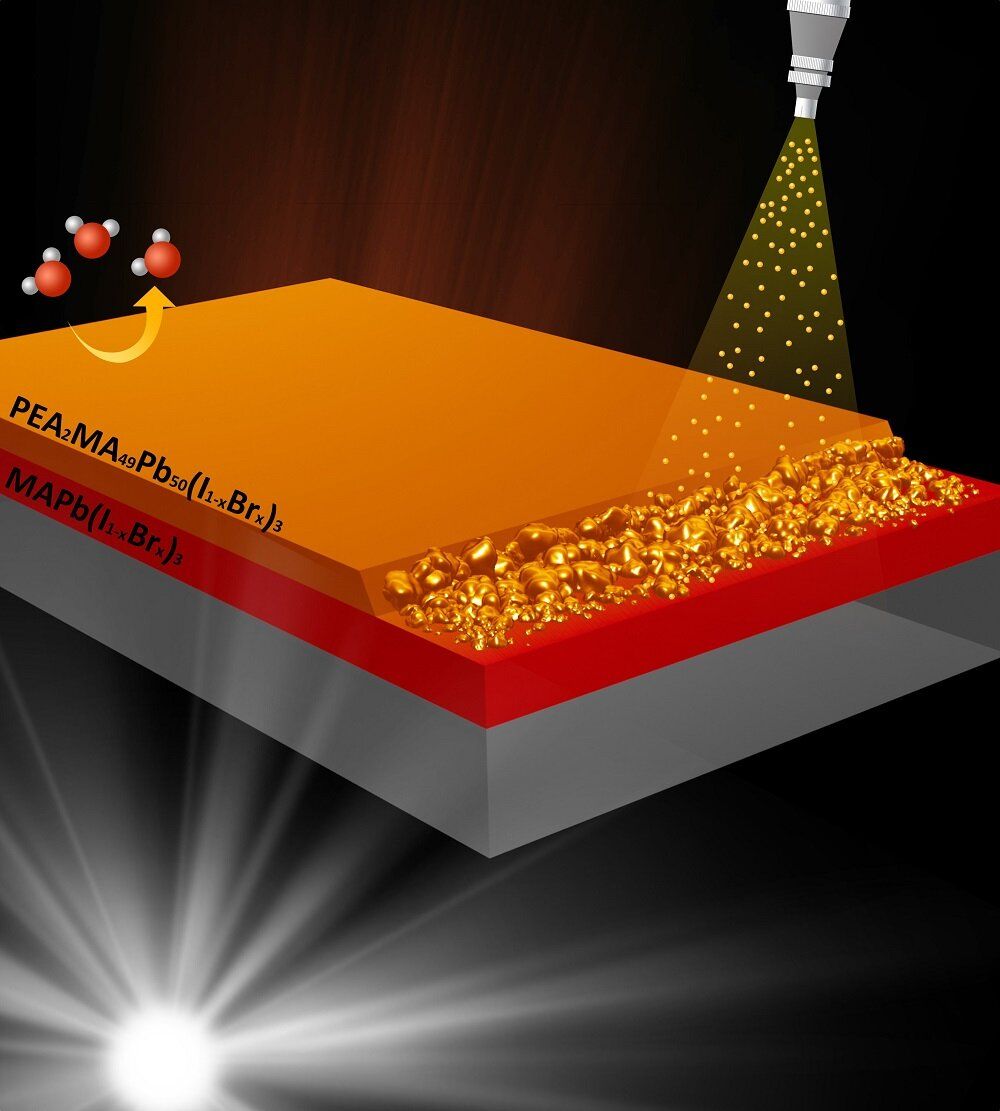

Although perovskites are a promising alternative to the silicon used to make most of today’s solar cells, new manufacturing processes are needed to make them practical for commercial production. To help fill this gap, researchers have developed a new precision spray-coating method that enables more complex perovskite solar cell designs and could be scaled up for mass production.

Perovskites are promising for next-generation solar cells because they absorb light and convert it to energy with better efficiency and potentially lower production costs than silicon. Perovskites can even be sprayed onto glass to create energy-producing windows.

“Our work demonstrates a process to deposit perovskite layer by layer with controllable thicknesses and rates of deposition for each layer,” said research team leader Pongsakorn Kanjanaboos from the School of Materials Science and Innovation, Faculty of Science, Mahidol University in Thailand. “This new method enables stacked designs for solar cells with better performance and stability.”

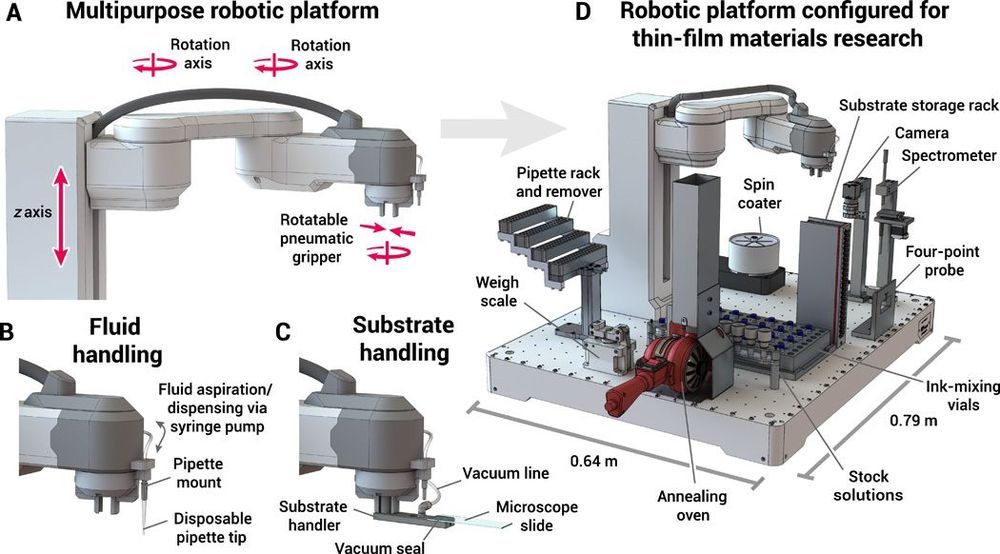

Discovering and optimizing commercially viable materials for clean energy applications typically takes more than a decade. Self-driving laboratories that iteratively design, execute, and learn from materials science experiments in a fully autonomous loop present an opportunity to accelerate this research process. We report here a modular robotic platform driven by a model-based optimization algorithm capable of autonomously optimizing the optical and electronic properties of thin-film materials by modifying the film composition and processing conditions. We demonstrate the power of this platform by using it to maximize the hole mobility of organic hole transport materials commonly used in perovskite solar cells and consumer electronics. This demonstration highlights the possibilities of using autonomous laboratories to discover organic and inorganic materials relevant to materials sciences and clean energy technologies.

Optimizing the properties of thin films is time intensive because of the large number of compositional, deposition, and processing parameters available (1, 2). These parameters are often correlated and can have a profound effect on the structure and physical properties of the film and any adjacent layers present in a device. There exist few computational tools for predicting the properties of materials with compositional and structural disorder, and thus, the materials discovery process still relies heavily on empirical data. High-throughput experimentation (HTE) is an established method for sampling a large parameter space (4, 5), but it is still nearly impossible to sample the full set of combinatorial parameters available for thin films. Parallelized methodologies are also constrained by the experimental techniques that can be used effectively in practice.

The journey took a very long time—505 days to fly 26,000 miles (42,000 km) at an average speed of about 45 mph (70 kph)—but pilots Bertrand Piccard and Andre Borschberg successfully landed the Solar Impulse 2 aircraft in Abu Dhabi on Tuesday, after flying around the world using only the power of the Sun. Solar Impulse 2 is a solar-powered aircraft equipped with more than 17,000 solar cells that weighs only 2.4 tons with a wingspan of 235 ft (72 m). Technical challenges, poor flying conditions, and a delicate aircraft all contributed to the slow pace. Gathered here are images from the record-setting circumnavigation, undertaken to help focus the world’s efforts to develop renewable energy sources.

A machine-learning algorithm has been developed by scientists in Japan to breathe new life into old molecules. Called BoundLess Objective-free eXploration, or Blox, it allows researchers to search chemical databases for molecules with the right properties to see them repurposed. The team demonstrated the power of their technique by finding molecules that could work in solar cells from a database designed for drug discovery.

Chemical repurposing involves taking a molecule or material and finding an entirely new use for it. Suitable molecules for chemical repurposing tend to stand apart from the larger group when considering one property against another. These materials are said to be out-of-trend and can display previously undiscovered yet exceptional characteristics.

‘In public databases there are a lot of molecules, but each molecule’s properties are mostly unknown. These molecules have been synthesised for a particular purpose, for example drug development, so unrelated properties were not measured,’ explains Koji Tsuda of the Riken Centre for Advanced Intelligence and who led the development of Blox. ‘There are a lot of hidden treasures in databases.’

Make no small plans. That seems to be the logic among the leaders of Algeria.

For some perspective, I just wrote about the corporate behemoth Amazon, which hopes to get to 100% renewable electricity by 2025 (firm target of 2030) and has a whopping total of 31 utility-scale wind and solar power plants built or planned that add up to 2,900 MW of total power capacity. That’s 2.3 gigawatts (GW). Algeria is talking about building 4 gigawatts of solar power capacity in 5 years. That’s a pretty stunning target.

Algeria does have a population of 44 million, making it the 32nd most populous country in the world. It also has ample sunshine. Nonetheless, 4 GW means increasing the country’s solar power capacity 10 times over, and that solar power capacity hasn’t changed much in the past 3 years.