Developing humanoid robots, unravelling the complexities of AI, and the mysteries of consciousness.

Welcome to the North of Patient podcast — conversations on health[beyond]care — where we paint an inspired landscape of healthcare’s future through dialogues with creative and unconventional thinkers from around the world.

For a summary of the episode, visit the blog post on North of Patient:

https://open.substack.com/pub/northofpatient/p/episode-13-dr…Share=true.

This week’s guest is the remarkable Dr. Suzanne Gildert. She’s a physicist, artist, and AI tech executive based in Vancouver on a mission to uncover the mysteries of consciousness and innovate unconscious AI.

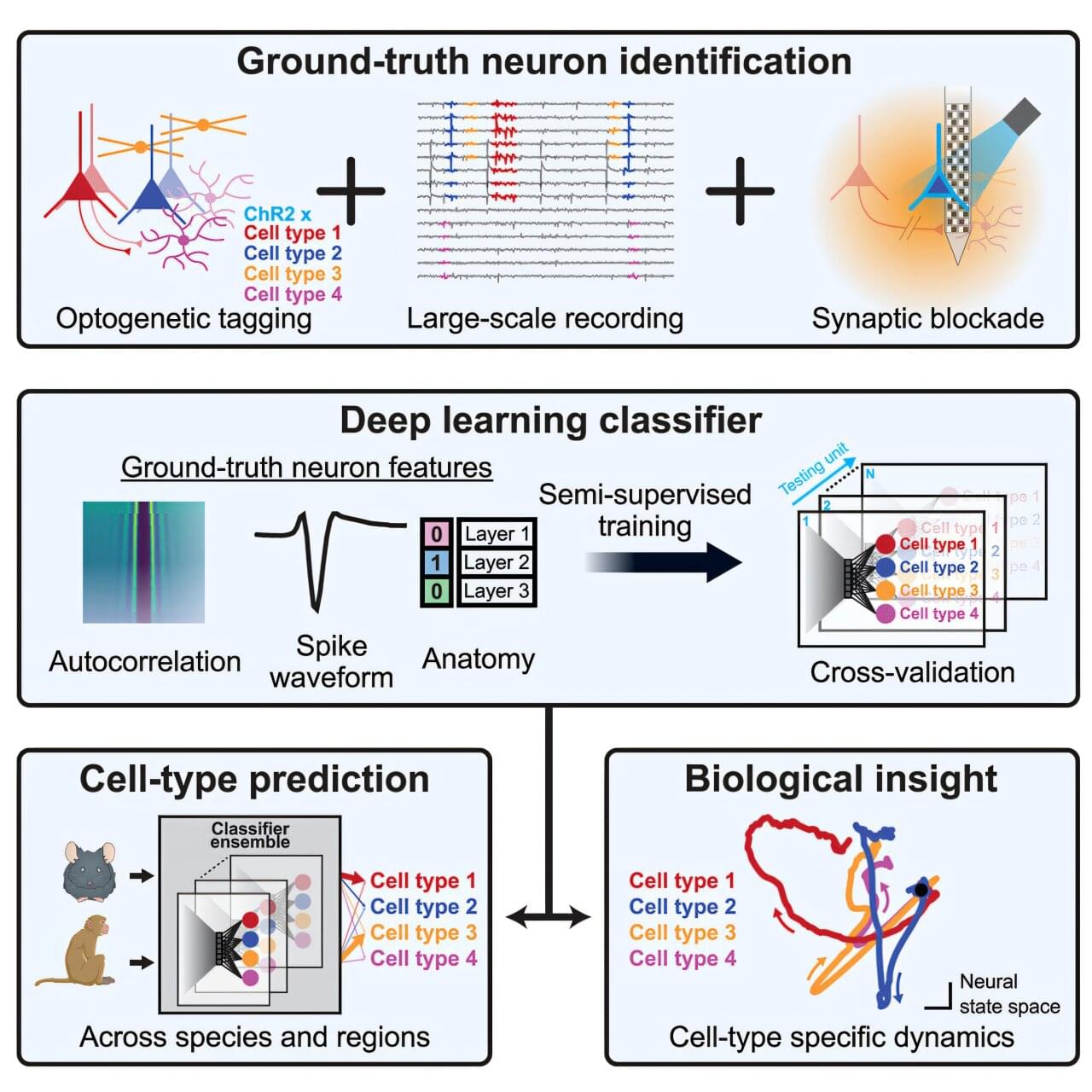

In this episode, we dive into the groundbreaking advancements and pressing challenges in quantum computing, examining the transformative potential of these technologies to reshape our world. Beyond the science, we also explore the philosophical dimensions of AI consciousness, questioning whether AI can ever truly replicate human experience and identity.

Learn more about Nirvanic AI: