A Python library for extracting structured information from unstructured text using LLMs with precise source grounding and interactive visualization. — google/langextract

Bruce and John are embracing AI innovation, one hug at a time.

In the latest episode of AI Bros, Bruce Burke and John Lawson III take listeners on a journey through the ever-evolving landscape of artificial intelligence, peppered with personal anecdotes and industry insights. Titled “From Purple Rain to AI’s Technology Reign,” this episode is a testament to the dynamic nature of technology and its impact on various sectors.

The conversation begins with a light-hearted discussion about Prince’s iconic “Sign O’ the Times” concert film, which is being re-released in IMAX. Bruce and John reminisce about the legendary artist’s influence and the technological advancements that have allowed his work to be experienced in new formats. This naturally leads into a broader conversation about how industries, including the adult industry, are often at the forefront of adopting new technologies.

As the discussion progresses, the focus shifts to the recent release of ChatGPT-5 by OpenAI. Bruce and John explore the mixed reactions from the tech community, highlighting the improvements in reasoning and factual accuracy promised by the new model. They delve into the implications of these advancements for businesses and consumers alike, noting the strategic moves by companies like OpenAI to make AI more accessible and integrated into everyday life.

A significant portion of the episode is dedicated to the economic impact of AI, particularly the rapid creation of wealth in the sector. Bruce shares insights from a report by CB Insights, revealing the unprecedented speed at which AI companies are minting new billionaires. The hosts ponder the sustainability of such rapid growth and the potential for a bubble, offering a thoughtful analysis of the current economic landscape.

Throughout the episode, John and Bruce also touch on the personalization features of AI models, which allow users to tailor interactions to their preferences. They discuss the emotional attachment users develop with AI, drawing parallels to the nostalgia some feel for older versions of technology. This personalization, they argue, offers both enhanced user experiences and potential challenges in managing user expectations.

As the episode draws to a close, Bruce and John reflect on the future of AI and its role in shaping industries and personal lives. They emphasize the importance of embracing innovation and staying informed about technological advancements.

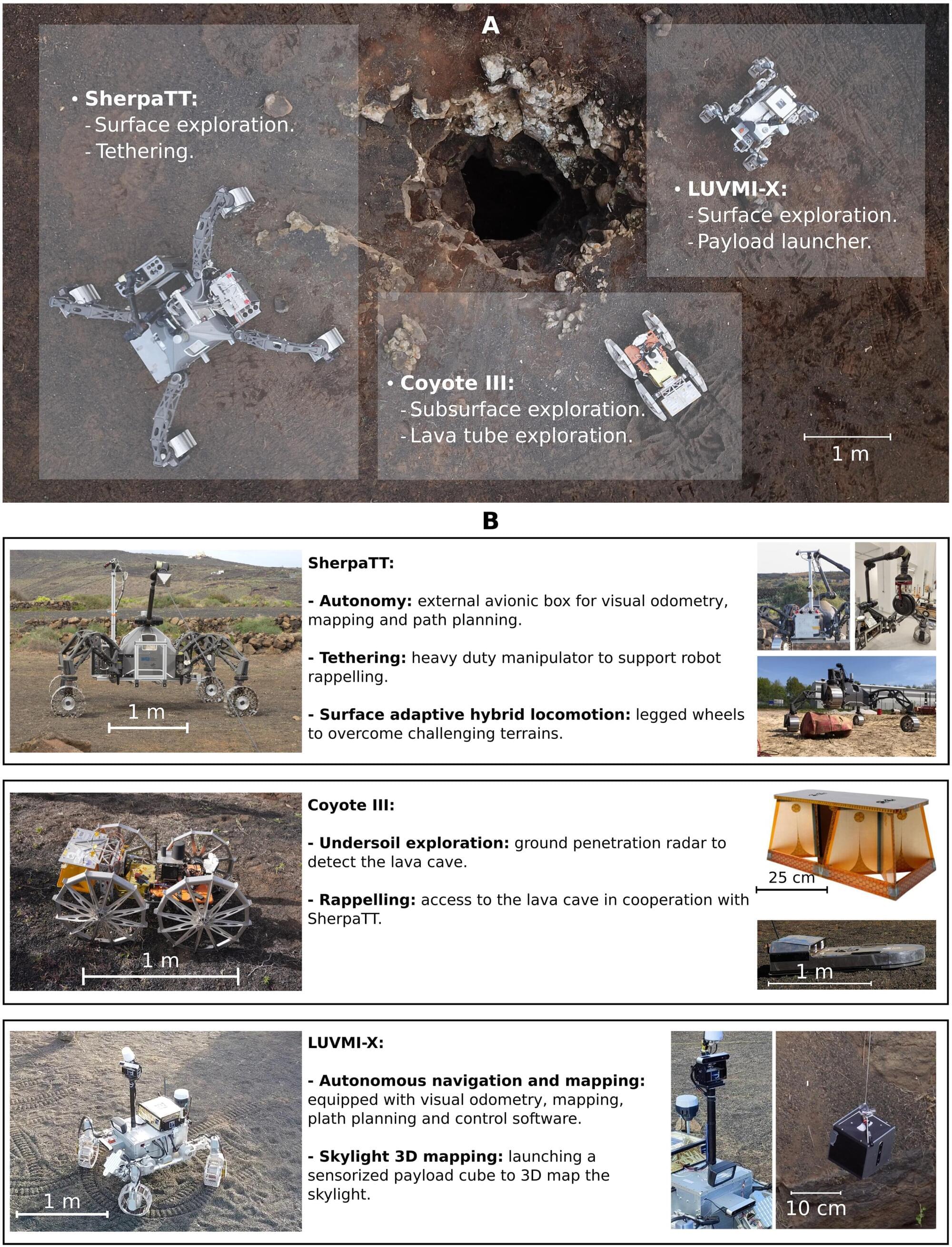

In the not-too-distant future, the search for signs of life on Mars and the moon could see the next generation of robots exploring a new frontier: subsurface lava tubes. These missions could also help us determine the best locations for establishing human bases.

To see whether this could be feasible, scientists tested three autonomous robots in a lava cave on the Spanish island of Lanzarote.

Lava tubes are deep underground caves formed by volcanic activity and are found in various parts of the world, as well as on Mars and the moon. These cavernous spaces could offer protection from the harsh environment of space, such as extreme temperatures, radiation and bombardment from meteorites. This means they may not only harbor existing life but could also serve as ideal locations for manned lunar and Martian bases.

US hid location trackers in AI chip shipments to spot diversions to China: Report.

Some chip shipments delivered from the United States to other locations had tracking devices, according to a report.

People familiar with the matter told a UK-based news agency that the location tracking devices were placed in shipments at high risk of illegal diversion to China.

The step reportedly aimed to restrict AI chip exports to destinations under the US administration’s curbs.

New AI method speeds up calculations to protect fusion reactors from plasma heat.

Scientists in the US have introduced a novel artificial intelligence (AI) approach that can protect fusion reactors from the extreme heat generated by plasma.

The new method, which is called HEAT-ML, was developed by researchers from Commonwealth Fusion Systems (CFS), the US Department of Energy’s (DOE) Princeton Plasma Physics Laboratory (PPPL), and Oak Ridge National Laboratory.

It is reportedly capable of quickly identifying magnetic shadows, which are critical areas protected from the intense heat of the plasma, and therefore help prevent potential problems before they start.

AI-powered brain implant restores speech in paralysis patient after 18 years.

UC Berkeley and UCSF use AI-driven brain-computer interface to restore near real-time speech in paralysis patient.

Discover how to create AI experiences with Copilot Studio and build low-code solutions using Microsoft Power Platform. Join the Microsoft Power Up Program today and get ready for the future of work.

Information tasks such as writing surveys or analytical reports require complex search and reasoning, and have recently been grouped under the umbrella of \textit{deep research} — a term also adopted by recent models targeting these capabilities. Despite growing interest, the scope of the deep research task remains underdefined and its distinction from other reasoning-intensive problems is poorly understood. In this paper, we propose a formal characterization of the deep research (DR) task and introduce a benchmark to evaluate the performance of DR systems. We argue that the core defining feature of deep research is not the production of lengthy report-style outputs, but rather the high fan-out over concepts required during the search process, i.e., broad and reasoning-intensive exploration. To enable objective evaluation, we define DR using an intermediate output representation that encodes key claims uncovered during search-separating the reasoning challenge from surface-level report generation. Based on this formulation, we propose a diverse, challenging benchmark LiveDRBench with 100 challenging tasks over scientific topics (e.g., datasets, materials discovery, prior art search) and public interest events (e.g., flight incidents, movie awards). Across state-of-the-art DR systems, F1 score ranges between 0.02 and 0.72 for any sub-category. OpenAI’s model performs the best with an overall F1 score of 0.55. Analysis of reasoning traces reveals the distribution over the number of referenced sources, branching, and backtracking events executed by current DR systems, motivating future directions for improving their search mechanisms and grounding capabilities. The benchmark is available at https://github.com/microsoft/LiveDRBench.

Detailed sources: https://docs.google.com/document/d/1ksVvFuR0IttxzH6zoASSYy7Z…b62ckaanow.

Based on the report: Situational Awareness — by Leopold Aschenbrenner https://situational-awareness.ai/from-agi-to-superintelligence/

Hi, I’m Drew! Thanks for watching smile

I also post mid memes on Twitter: https://twitter.com/PauseusMaximus.

Also, I meant to say Cortés conquered the Aztecs, not the Incas.