These are the buzziest talking points and biggest developments in enterprise automation for the next year.

A new video released by nonprofit The Future of Life Institute (FLI) highlights the risks posed by autonomous weapons or ‘killer robots’ – and the steps we can take to prevent them from being used. It even has Elon Musk scared.

Its original Slaughterbots video, released in 2017, was a short Black Mirror-style narrative showing how small quadcopters equipped with artificial intelligence and explosive warheads could become weapons of mass destruction. Initially developed for the military, the Slaughterbots end up being used by terrorists and criminals. As Professor Stuart Russell points out at the end of the video, all the technologies depicted already existed, but had not been put together.

Now the technologies have been put together, and lethal autonomous drones able to locate and attack targets without human supervision may already have been used in Libya.

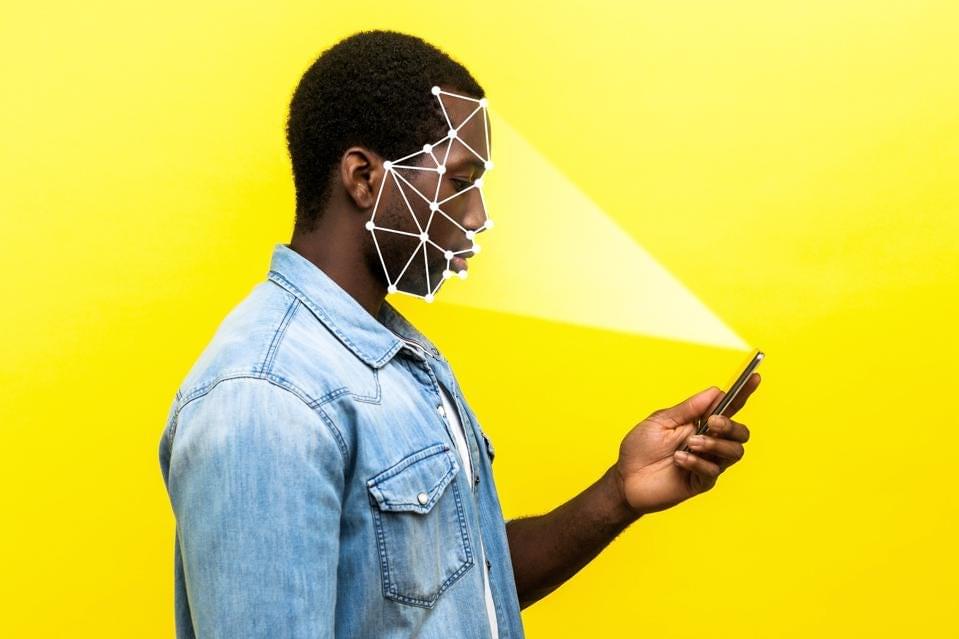

Meta, the company formerly known as Facebook is pulling the plug on its facial recognition program. The company is planning to delete more than one billion people’s individual facial recognition templates, and will no longer automatically recognize people’s faces in photos or videos as a result of this change, according to its own post. The use of facial recognition technology has a disparate impact on people of color, disenfranchising a group who already face inequality, and Facebook seems to be acknowledging this inherent harm. The Breakdown You Need to Know.

CultureBanx reported that Meta seems to always be embroiled in corporate drama and with intense scrutiny. When you add that to the growing concern from users and regulators that facial recognition space remains complicated, an exit makes sense. More than 600 million daily active users on Facebook had opted into the use of the face recognition technology.

Research shows commercial artificial intelligence systems tend to have higher error rates for women and black people. Some facial recognition systems would only confuse light-skin men 0.8% of the time and would have an error rate of 34.7% for dark-skin women. Just imagine surveillance being used with these flawed algorithms. A 2018 IDC report noted it expects worldwide spending on cognitive and AI systems to reach $77.6 billion in 2022.

The bot is a platform that will used to test more robotic technologies.

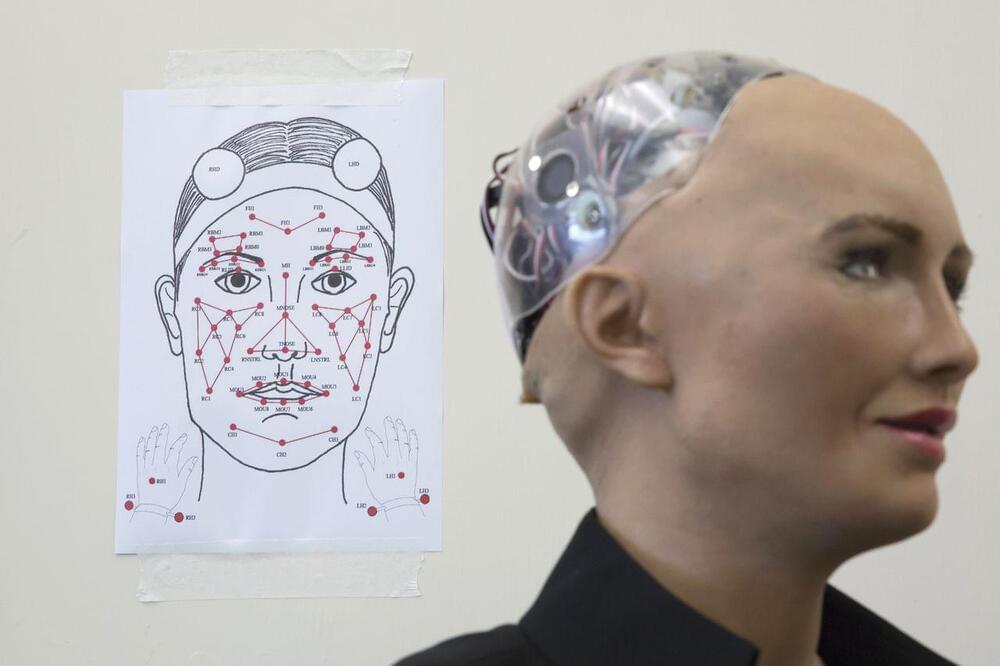

A U.K.-based company Engineered Arts has developed a humanoid robot that can display human-like expressions with ease. In a short video released on YouTube, the company shows off its most advanced humanoid, dubbed Ameca, which is initially a platform for testing robotic technologies.

With new developments in artificial intelligence, machines are learning to not only do human tasks but also go further beyond. However, for humans and machines to work together more fluidly, machines need to occupy the same space and humanoids are the best platforms to do this. Researchers have been working to make humanoids more interactive by teaching them non-verbal communication and Ameca is quite a milestone in this area.

As is seen in the video above, the humanoid appears to have woken up in a robotic laboratory while an actual human is busy working in the background. The robot moves its arms, shows a flurry of expressions in a matter of seconds, and even expresses amazement at how its hands and fingers move fluidly before looking at the camera quite surprised. The teaser is a sufficient demonstration of what the robot can do when it comes to the upper half of the body.

Full Story:

The winning face must be “kind and friendly.”

Could you use an extra $200K? That’s what a Russian robotics company is offering to pay someone who’s willing to surrender the rights to their face and voice — forever — for use in robot development. They’re looking for a face that’s “kind and friendly,” reports say.

According to a report by Newsweek, the company, named Promobot, is known for producing “hyper-realistic, humanlike” robots. In 2019, the Promobot company launched the “Android Robo-C,” a made-to-order robot that could be modeled after anyone’s appearance.

Currently, the report said, Promobot is looking for a face as a model for “a humanoid robot-assistant which will work in hotels, shopping malls and other crowded places.”

Engineered Arts has provided a sneak preview of its latest robot, Ameca, which it claims is the most advanced android ever built. The machine will be on display at CES 2022.

Founded in 2005, Engineered Arts is a UK-based company that designs and manufacturers humanoid entertainment robots. Its first machine, RoboThespian, appeared on stage at the Eden Project in Cornwall. Since then, the company has installed more than 100 robots at exhibitions, science centres, theme parks and other venues worldwide. Over the years, its robots have evolved to have more realistic human movements and ways of interacting with people.

Ameca, seen briefly in the video below, is the newest addition to the line-up – described as “the world’s most advanced human shaped robot, representing the forefront of human-robotics technology.”

Meet Ameca: with eerily realistic facial expressions and movements…

Cornwall-based Engineered Arts, which brands itself ‘the UK’s leading designer and manufacturer of humanoid entertainment robots’, unveiled the machine on YouTube to much excitement.

Many viewers expressed their amazement at how realistic and human-like the machine is.

One user wrote: ‘I know we’re supposed to be scared of AI, but this is the first gynoid that hasn’t creeped me out. It’s pretty cool.’

Scientists with the help of next gen Artificial Intelligence managed to create the smallest and most efficient camera in the world. A specialist medical camera that measures just under a nanometer has just entered the Guinness Book of Records. The size of the grain of sand, it is the camera’s tiny sensor that is actually being entered into the world-famous record book, for being the smallest commercially available image sensor.

–

TIMESTAMPS:

00:00 A new leap in Material Science.

00:57 How this new technology works.

03:45 Artificial Intelligence and Material Science.

06:00 The Privacy Concerns of Tiny Cameras.

07:45 Last Words.

–

#ai #camera #technology

Engie and Macquarie to build 150MW one hour battery at site of shuttered Hazelwood coal generator.

French energy giant Engie and Macquarie’s Green Investment Group are to jointly fund the construction of a 150MW/150MWh big battery at the site of the now closed Hazelwood brown coal generator.

The announcement, which comes four years after Engie closed what was Australia’s dirtiest power station, continues the trend of using the sites of closed or ageing coal and gas plants to build battery storage to support the switch to 100 per cent renewables.

Construction has already begun on the Hazelwood Battery, which will be built and maintained over a 20-year period by US-based Fluence, using – for the first time in Australia – its sixth-generation Gridstack product and its AI-enabled bidding system.

The robot navigates using sensors and removes weeds mechanically without the need for chemicals. The LiDAR (light detection and ranging) scanners installed in the weed killer continuously emit laser pulses as the vehicle moves, which are then reflected by objects in the surrounding area. This produces a 3D point cloud of the environment, which helps mobile weed killers to find their way and determine the position of plants or trees. “AMU-Bot is not yet able to classify all plants; however, it can recognize crops such as trees and shrubs in the rows of the tree nursery cultivations,” said the team leader Kevin Bregler.

The weeds in the spaces between the plants or trees are also reliably eliminated. To do this, the manipulator moves into the gaps between the crops. The weeds do not need to be collected separately and are left on the ground to dry out. Thanks to its caterpillar drive, the self-driving weed killer moves along the ground with ease and is extremely stable. Even holes in the ground created when saplings are removed do not pose a problem for AMU-Bot. The AMU-Bot platform is economical, robust, easy to use, and at the same time highly efficient.

The project is funded by the German Federal Office of Agriculture and Food. The AMU-Bot platform relies on the ingenious interaction of three sophisticated modules: caterpillar vehicle, navigation system, and manipulator. Bosch is responsible for the navigation and the sensor system, while KommTek developed the caterpillar drive. The Fraunhofer IPA designed the height-adjustable manipulator, including rotary harrows, and was responsible for overall coordination.