In forthcoming years, everyone will get to observe how beautifully Metaverse will evolve towards immersive experiences in hyperreal virtual environments filled with avatars that look and sound exactly like us. Neil Stephenson’s Snow Crash describes a vast world full of amusement parks, houses, entertainment complexes, and worlds within themselves all connected by a virtual street tens of thousands of miles long. For those who are still not familiar with the metaverse, it is a virtual world in which users can put on virtual reality goggles and navigate a stylized version of themselves, known as an avatar, via virtual workplaces, and entertainment venues, and other activities. The metaverse will be an immersive version of the internet with interactive features using different technologies such as virtual reality (VR), augmented reality (AR), 3D graphics, 5G, hologram, NFT, blockchain, haptic sensors, and artificial intelligence (AI). To scale personalized content experiences to billions of people, one potential answer is generative AI, the process of using AI algorithms on existing data to create new content.

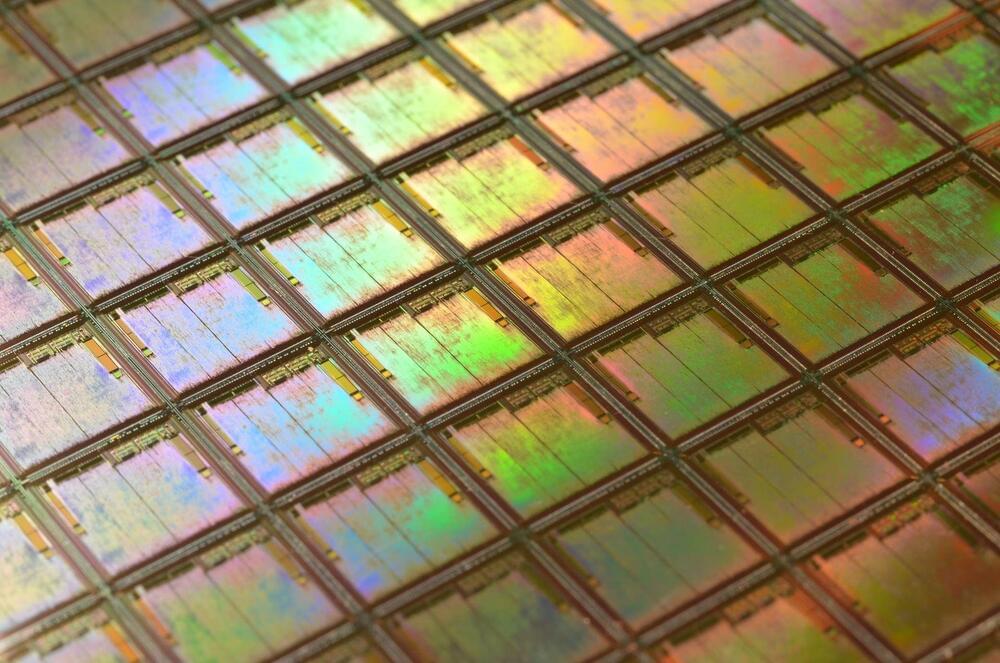

In computing, procedural generation is a method of creating data algorithmically as opposed to manually, typically through a combination of human-generated assets and algorithms coupled with computer-generated randomness and processing power. In computer graphics, it is commonly used to create textures and 3D models.

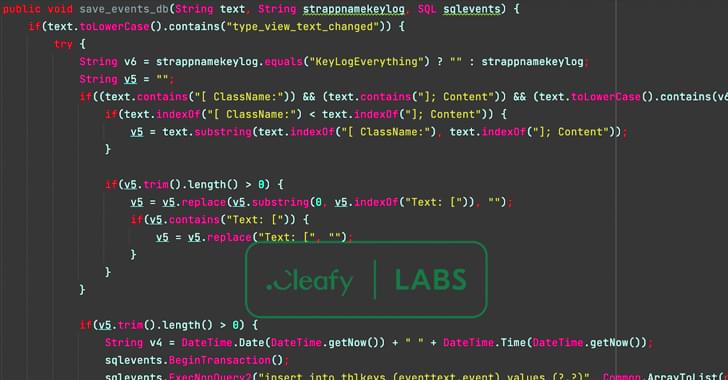

The algorithmic difficulty is typically seen in Diablo-style RPGs and some roguelikes which use instancing of in-game entities to create randomized items. Less frequently it can be used to determine the relative difficulty of hand-designed content to be subsequently placed procedurally, as can be seen with the monster design in Unangband. For example, the designer can rapidly create content, but leaves it up to the game to determine how challenging that content is to overcome, and consequently where in the procedurally generated environment this content will appear. Notably, the Touhou series of bullet hell shooters use algorithmic difficulty. Though the users are only allowed to choose certain difficulty values, several community mods enable ramping the difficulty beyond the offered values.